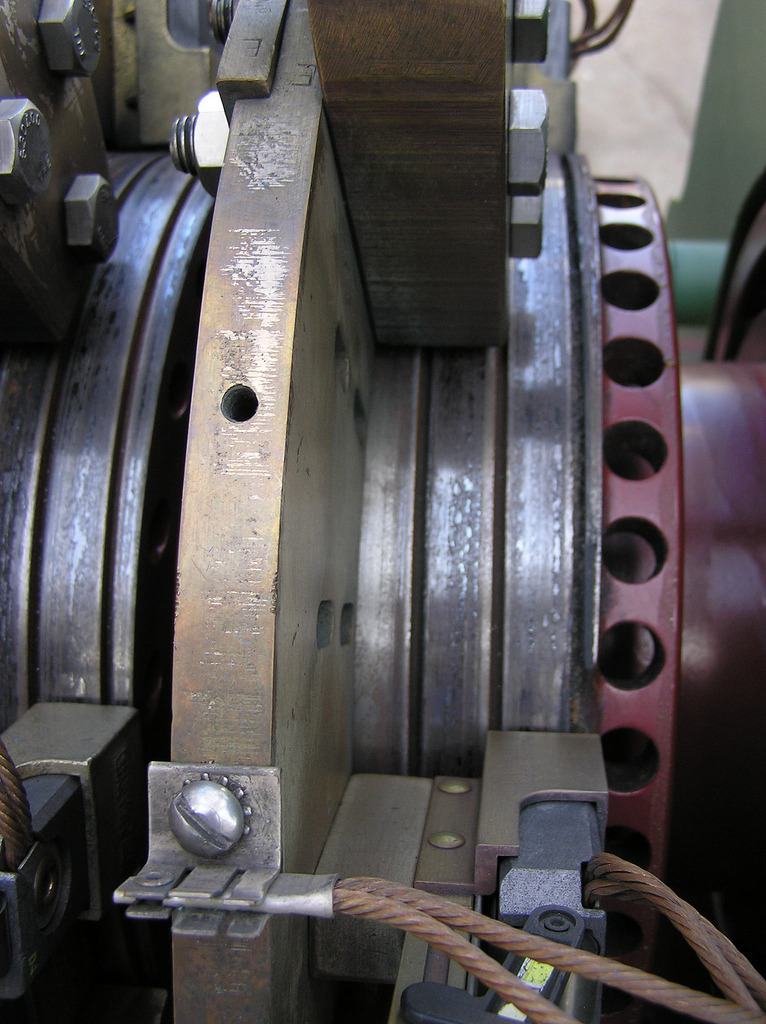

Caused by a compromised brush-to-ring connection. Brush box restrictions like carbon deposits, poor spring pressure and out-of-round rings are the most frequent culprits of visible arcing. Without proper maintenance, this arcing can escalate into a catastrophic ring fire causing equipment damage and a forced outage.

Any restrictions present in the brush box can restrict the brush moving freely in the box. Some examples:

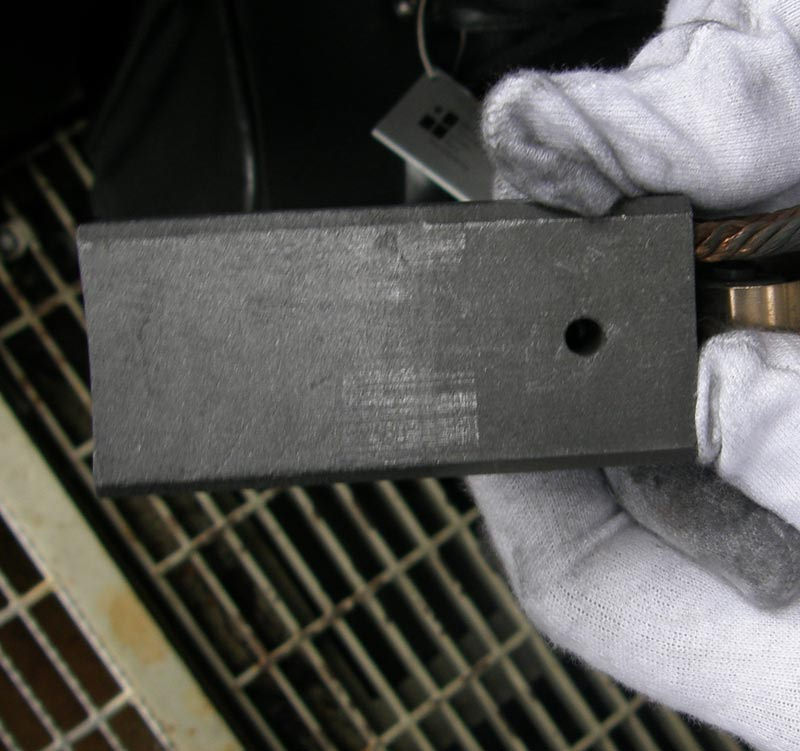

- A bent brush holder that was dropped

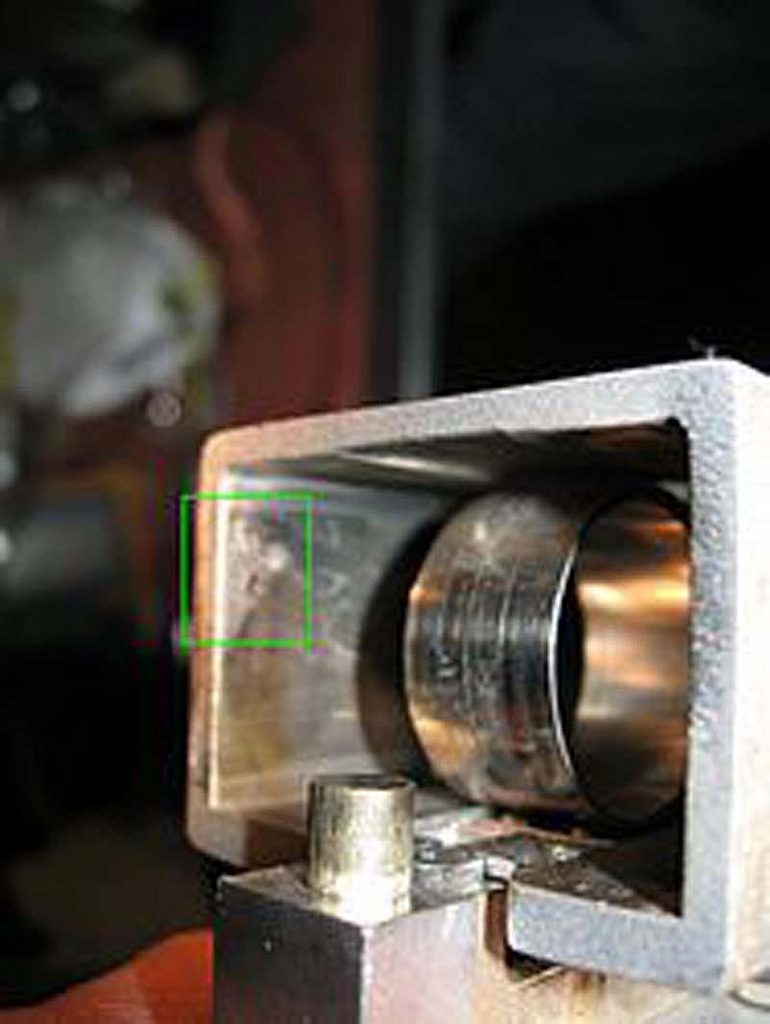

- A rough edge or burr on the brush box interior wall

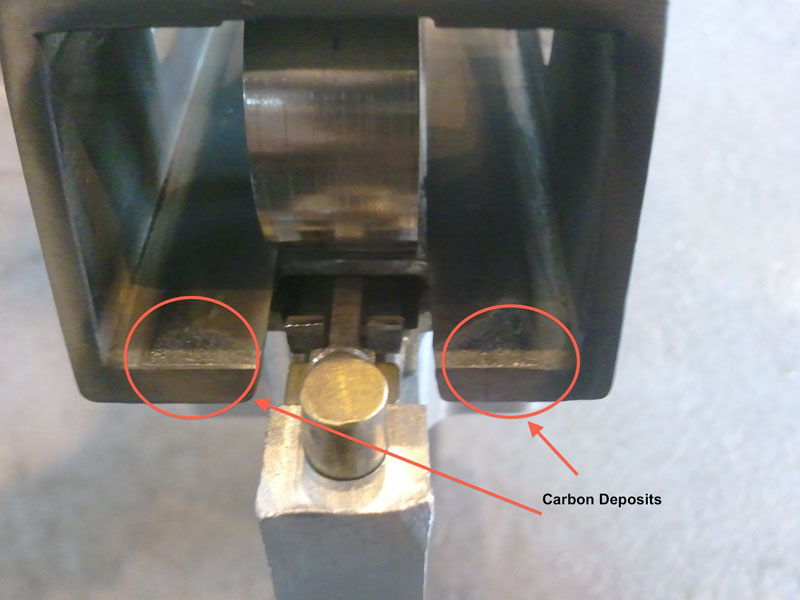

- Carbon deposit buildup (hardened, not carbon dust)

- Spring pressure from constant pressure springs. Creates a sideways pressure causing the brush to bind.

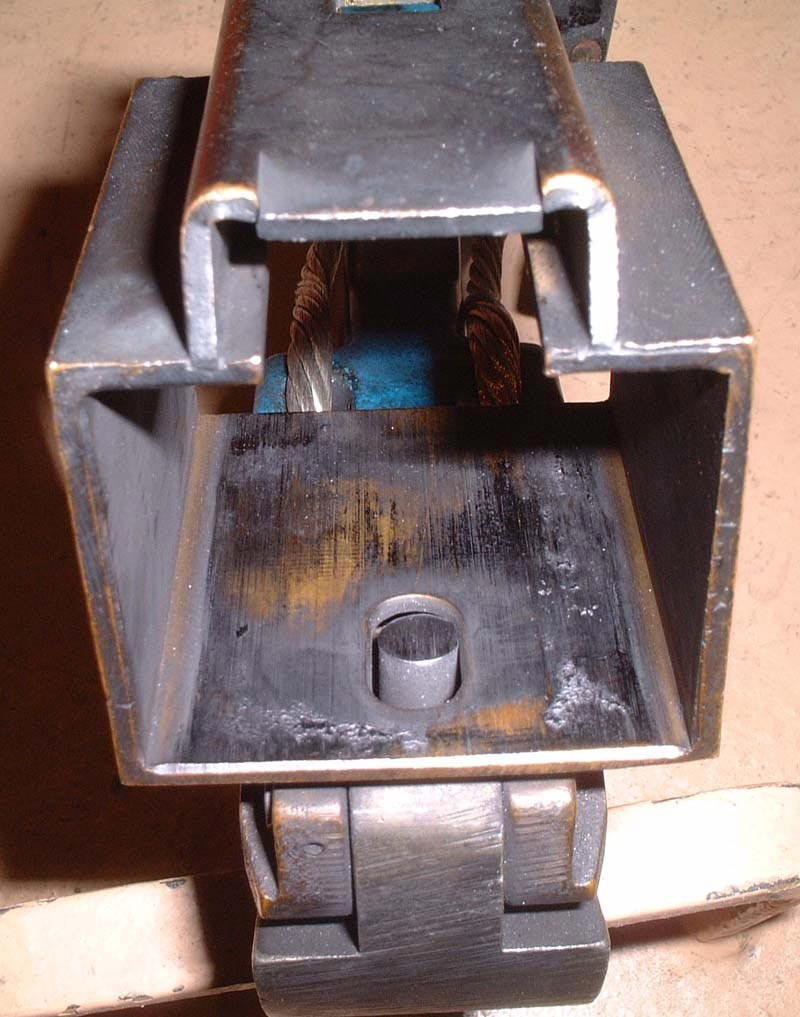

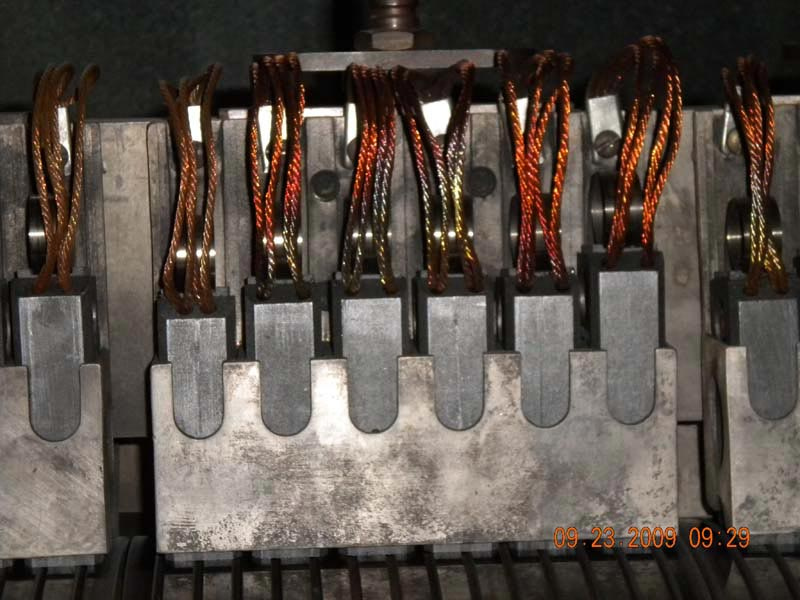

Small, hardened carbon deposits (not carbon dust) that adhere to the brush box wall caused by the repetitive impact of the brush against the brush box in high speed turbine generators.

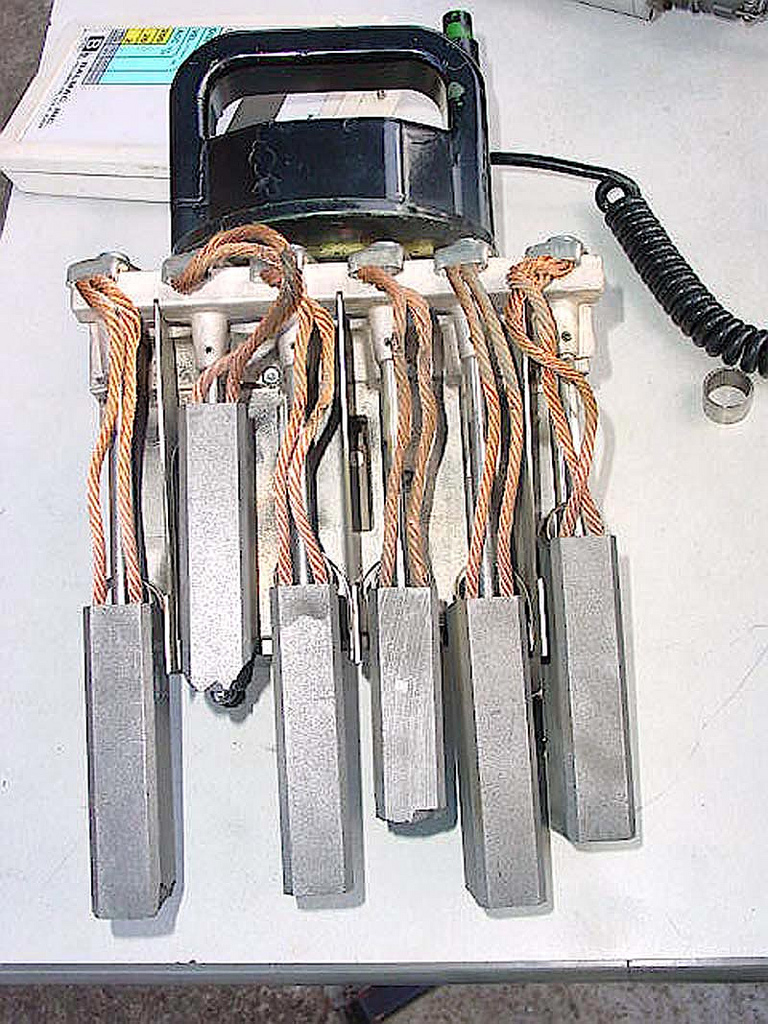

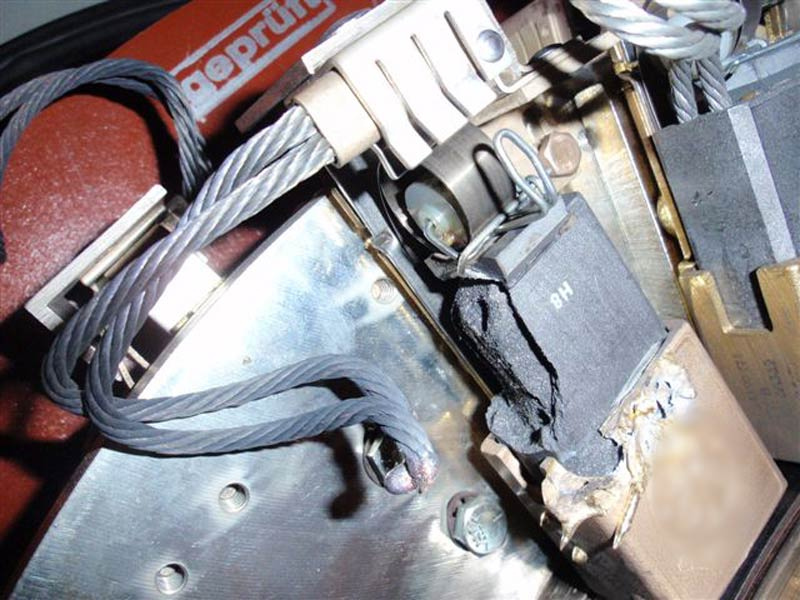

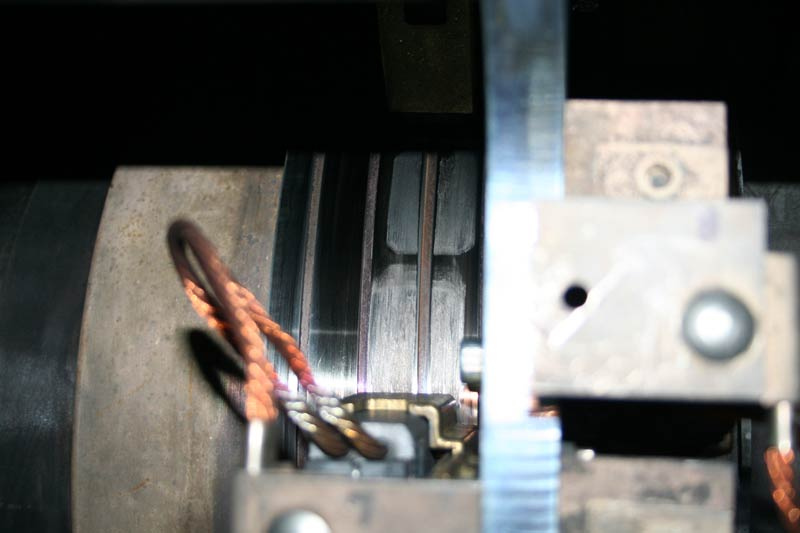

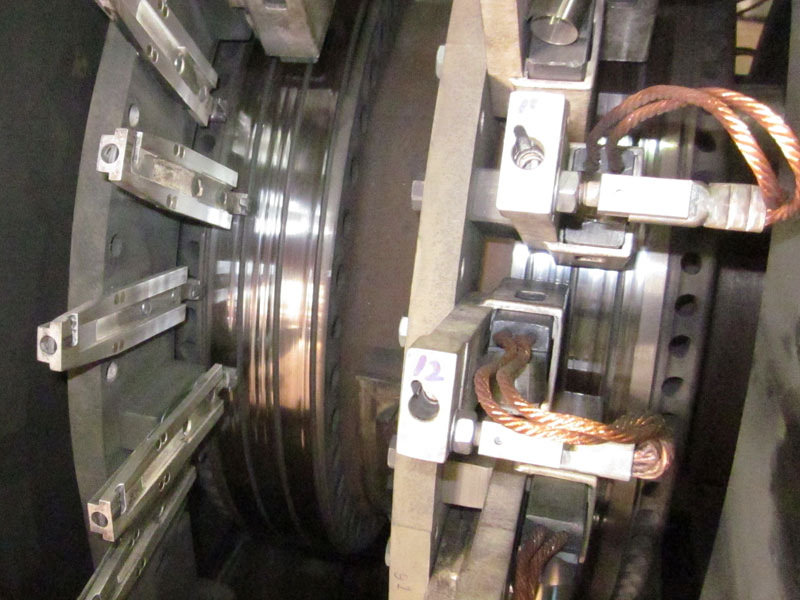

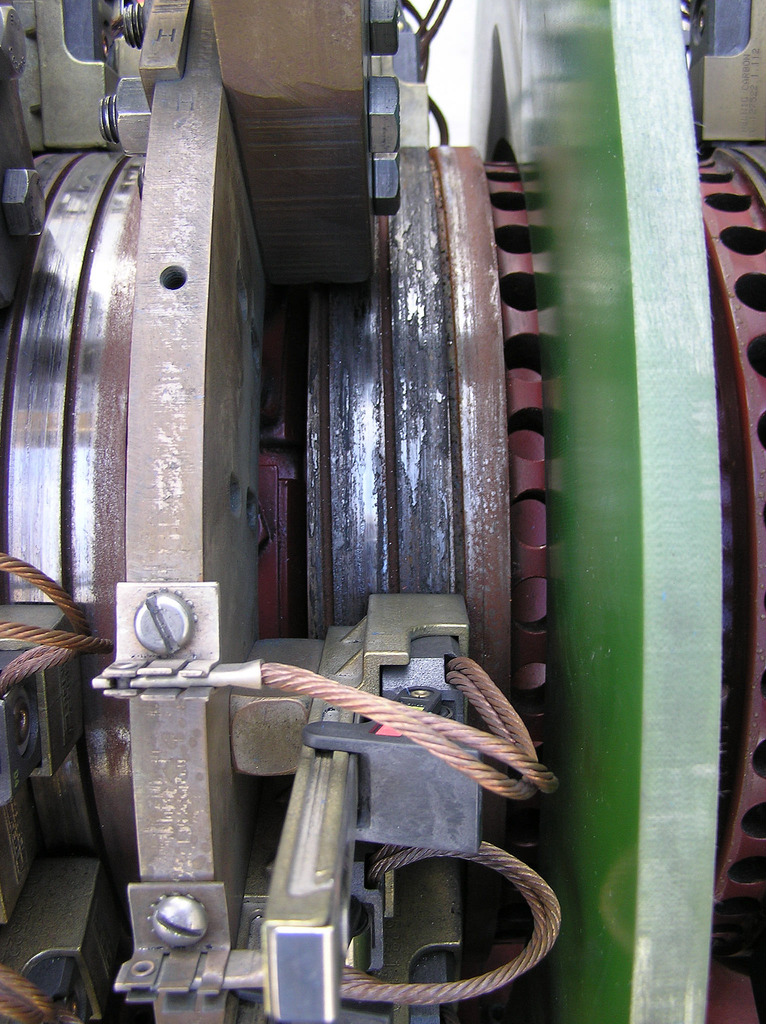

This happens when the brush box becomes the primary current path. Can be caused by burned/overheated shunts. Brush box becomes pitted from electrical erosion. This electrical erosion can often be seen on the brush as well.

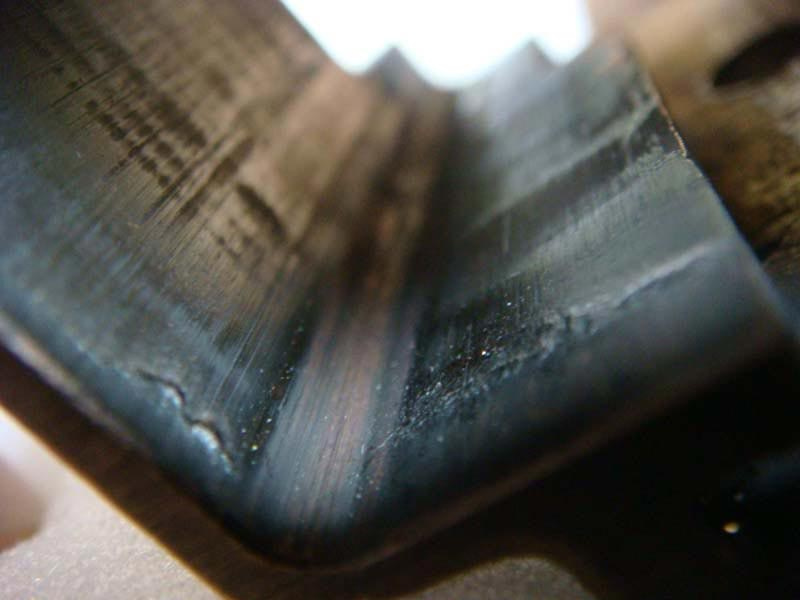

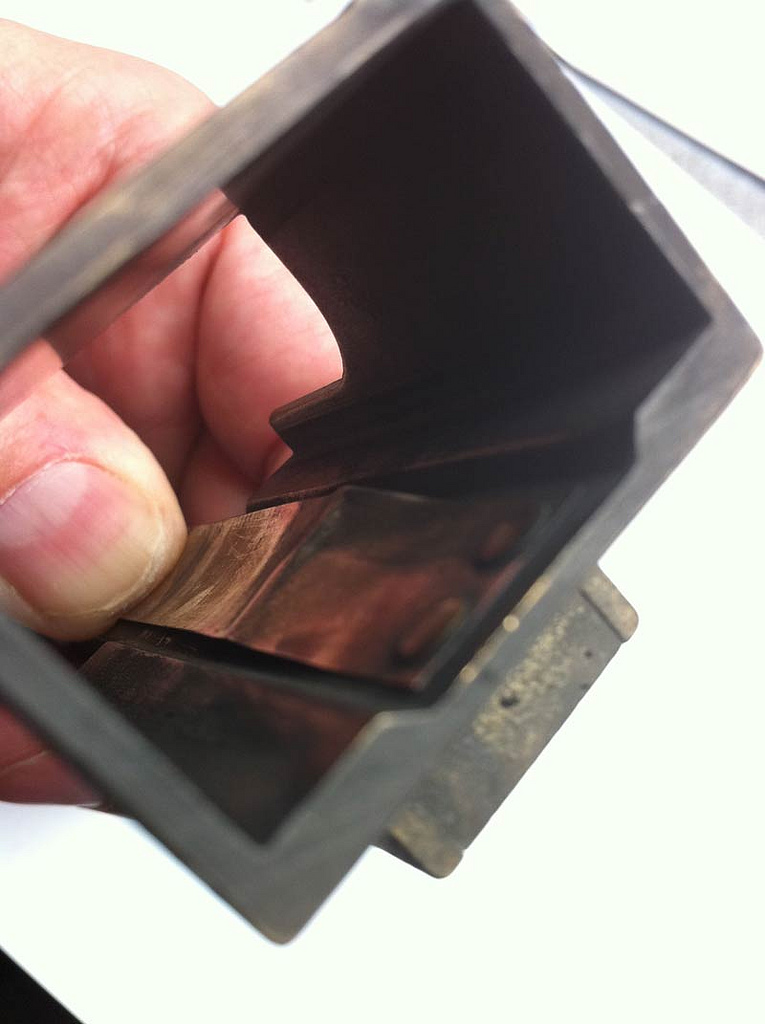

Brush can become chipped when the collector ring becomes out-of-round causing the brush to move (or chatter) in the brush box. Chipping of brushes can occur when brush chatter reaches > 10-15mls.

Brush catch mechanisms from some OEM and aftermarket brush holders can chip the brushes when they are not working properly. Brushes can also chip if they are not fully riding on the collector ring surface.

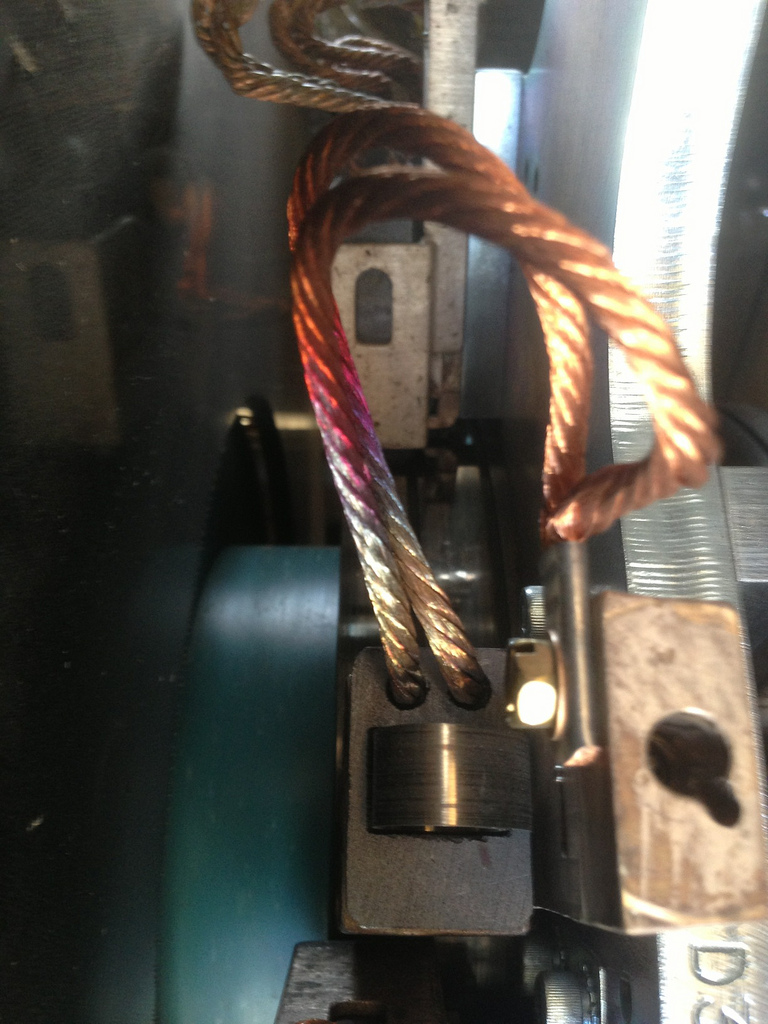

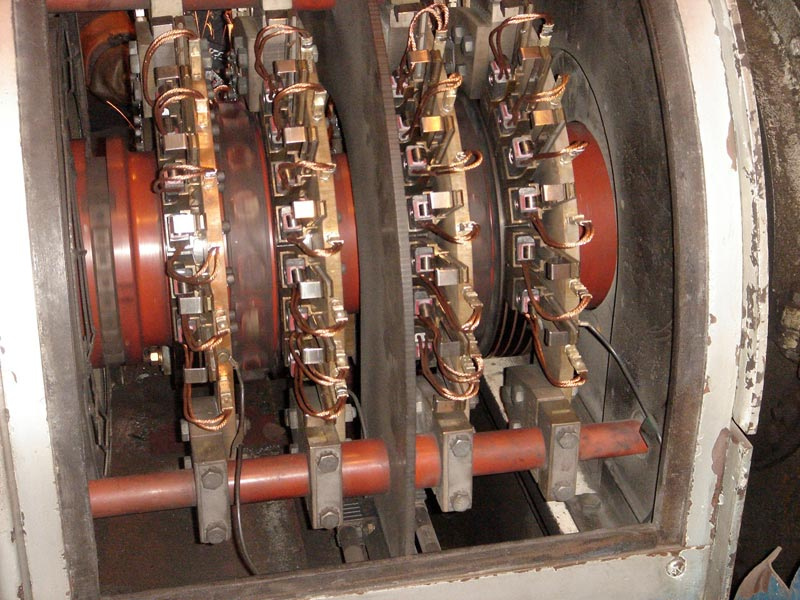

Selective action causes an overheating of shunts that lead to discoloring. A silvering of the shunt (see photo) can be an indicator that selective action is occurring – the brush is carrying too much current.

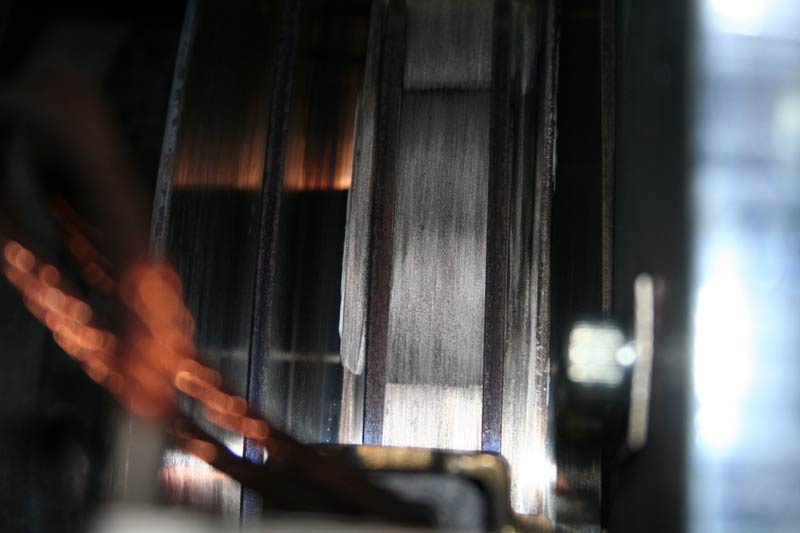

Also called imaging, footprinting, or ghosting, this is a common phenomena where the brush-to-ring connection is compromised. The marks are signs of electrical erosion resulting in a compromised connection which affects the concentricity (or roundness) of the ring. The ring surface can be observed by using a strobe when the unit is in operation. Taking digital pictures can also capture photographing while the unit is running.

Contamination, rust, and dirty air can all negatively affect the surface of the collector ring. These conditions can cause rapid brush wear, affect the brush film (or patina) and cause problems with the transfer of current from the ring through the brushes.

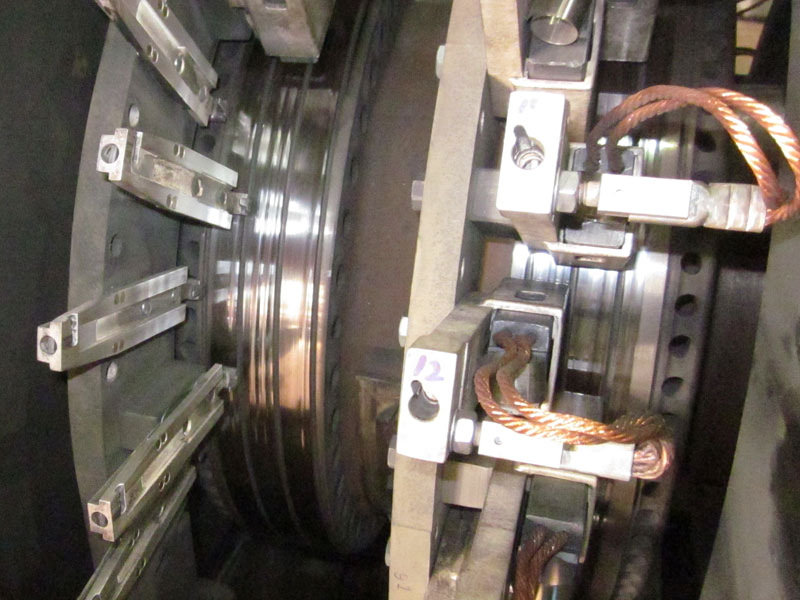

Poorly designed and poorly maintained terminal connections can become trouble points for your brush holders. These connection points are difficult to maintain and are therefore not serviced regularly. The pictures show loose or burned connection points which can be trouble spots for arcing.

OEM and aftermarket brush holder spring designs do not allow for easy replacement. The spring is usually riveted to the spring clip or magazine type holder. Weakened or over-sprung springs compromise the brush-to-ring connection. Cutsforth brush holder’s spring is easily replaced. We provide a new spring with every brush eliminating this common problem.

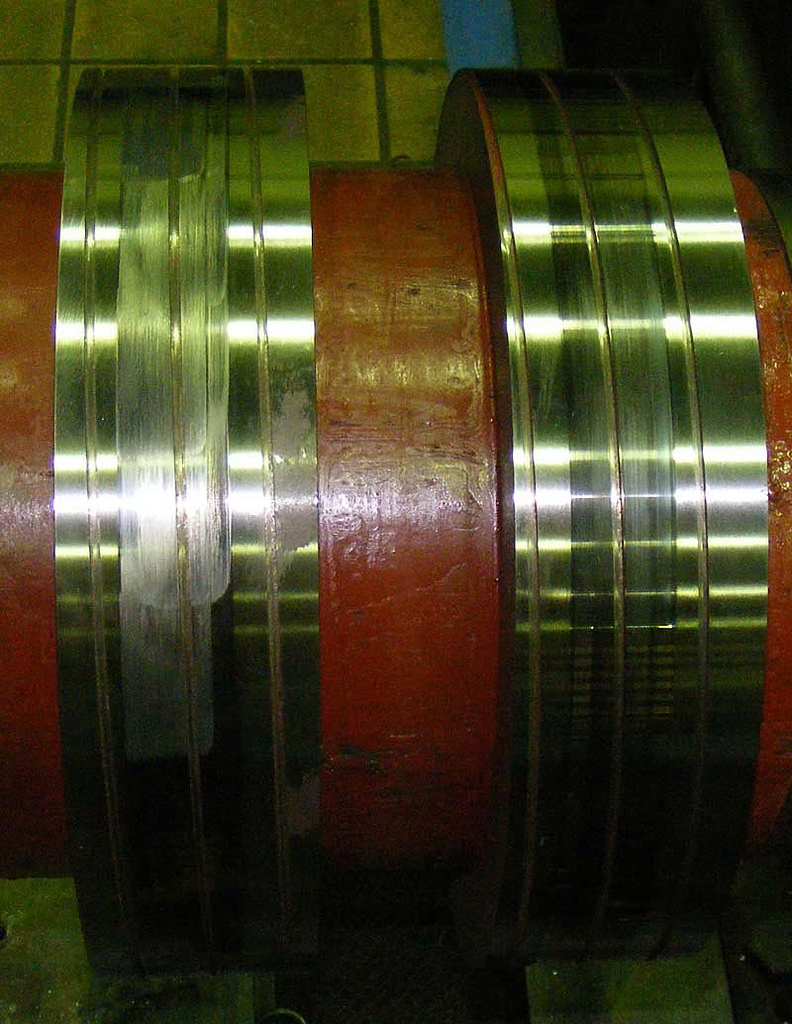

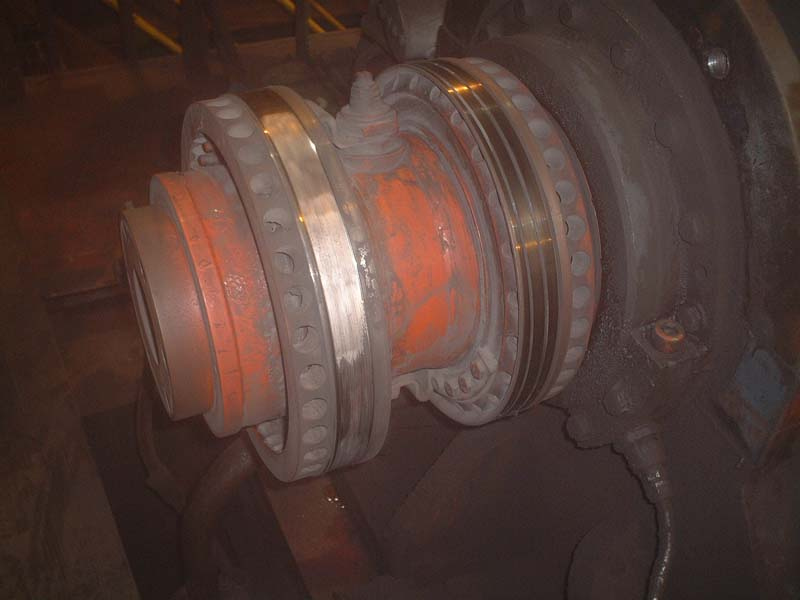

Collector rings and commutators are grooved from mechanical and electrical brush wear. Unfiltered air and oil contamination can increase the ring wear as well. Cutsforth Online Truing Service can restore the ring surface without shutting down.

If any part of the spiral groove is worn below .035″ or is missing, the groove should be restored to prevent selective action related problems. Cutsforth Spiral Groove Restoration saves valuable outage time and maintenance dollars.

Flat or low spots on the collector ring or commutator from electrical erosion increases brush vibrations (or brush chatter) and vibration related brush holder problems. This out-of-roundness will not be noticeable to the naked eye. Cutsforth Online Truing Service addresses out-of round collector rings and commutators since it is performed at operating speed and temperature.