Thermography

Monitoring

Features

- 24×7 non-invasive temperature monitoring

- Monitor multiple cameras with same Continuous Monitoring System

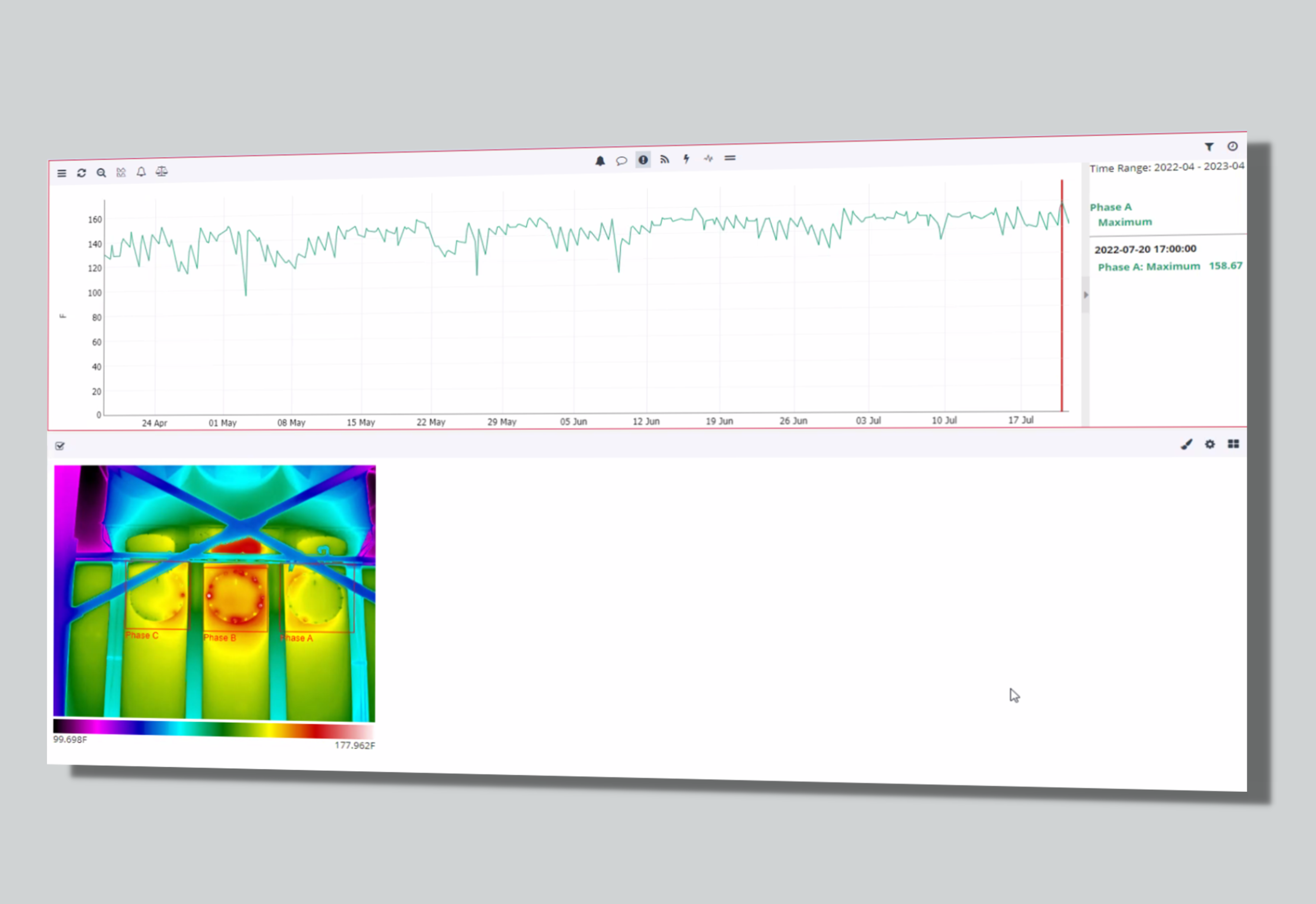

- View radiometric image in InsightCM

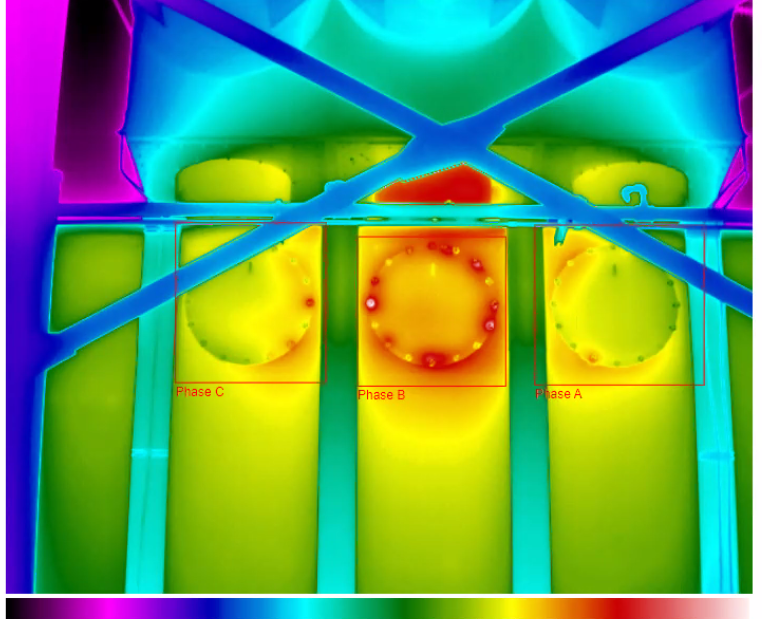

- Draw virtually unlimited regions of interest (ROIs) around assets in the image

- For each region of interest (ROI), InsightCM captures and trends the minimum, maximum, average, and delta between ROIs

- Common assets: Generator Step Up Transformers (GSUs), motors, breakers, panels

Failure Modes Detected

- Mechanical: improper lubrication, misalignment, friction points

- Electrical: insulation breakdown, loose connections

Wired Infrared Monitoring

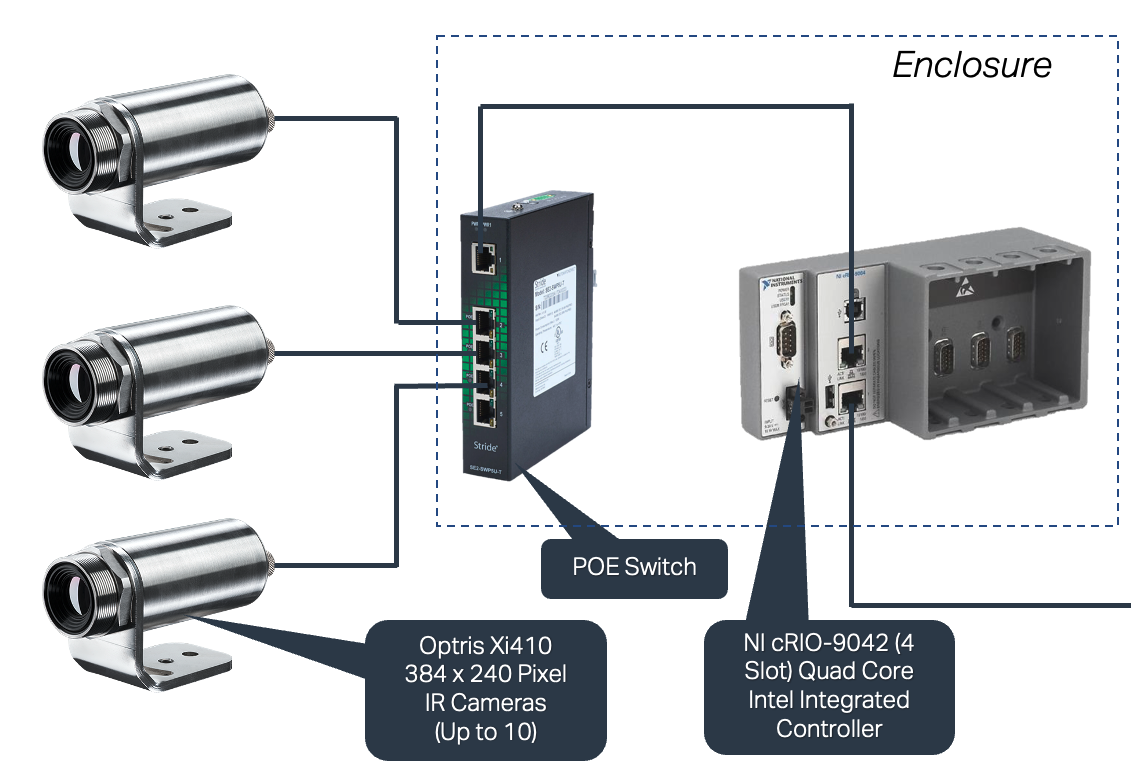

For monitoring a transformer, the tank temperature and the temperature of each individual bushing could be trended, alarmed on, and the temperature values shared as tags with the historian. InsightCM supports the Optris Xi410 camera at a resolution of 320×240 pixels. Each infrared monitoring system can connect with up to ten cameras.

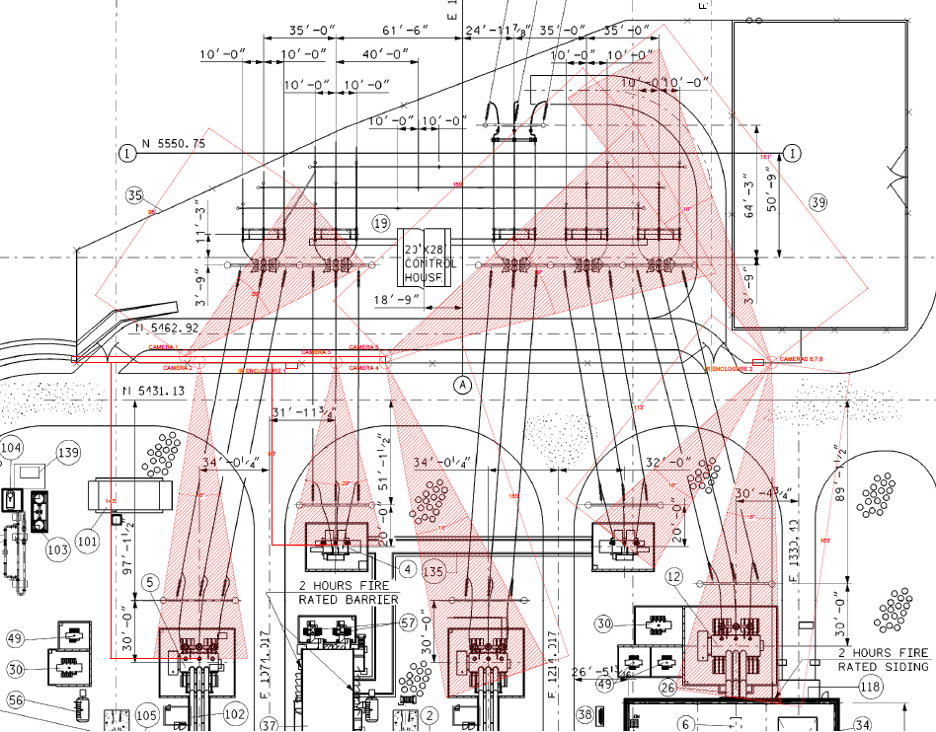

- Assets:

- 3 – GSU Transformers

- 2 – Station Service Transformers

- 5 – Switchyard Air Switches

- 1 – Switchyard Main Switch

- 1 – Transmission Switch

- 150 Regions of Interest (ROIs)

- 25 deltas between ROIs

- Data trended in InsightCM at the plant level with the M&D center using APR tools to model all of these points with other variables like ambient temp, load, etc.

Erbessd Wireless Infrared Monitoring

InsightCM also supports the Erbessd EPH-T70, wireless Infrared (IR) camera. This camera is intended to be used in power electronics and switchgear applications within the cabinet itself. This eliminates the need to create an IR window (design modification) within a cabinet for use with a handheld IR camera. It also allows for automated data collection of temperature without relying on manual, route-based collection of high-voltage assets where arc flash is a concern. The camera has a relatively low resolution (32×24 pixels) in comparison with the Cutforth hard-wired IR solution featuring the Optris Xi410, but it is cost-effective and suitable for identifying hot spots.