Prioritize Reliability

With age and demand on plants increasing and budgets and personnel in decline, organizing and implementing these programs can relieve pressure on finances, operations, and equipment

– Improving reliability of all assets throughout the fleet

– Increasing the capabilities of the maintenance, operations, and engineering workforce

– Optimizing capital expenditures across the fleet by increasing risk-informed decision making

– Improving thermal performance / net output

– Eliminating low value manual work activities and increase process efficiencies through digital transformation

– Increasing advanced analytics capability to improve early detection and correction of equipment anomalies

Equipment Reliability and Asset Management processes, integrates, and coordinates a broad range of ER activities into one process so plant personnel may establish optimal preventive maintenance tasks. Personnel are able to make operational, risk management, and equipment adjustment decisions based on equipment health and maintenance feedback.

Equipment Reliability (ER)/Digital Transformation Workshops

- ER Process/Program Management/Leadership Training

- ER Program Assessment (Industry Standards & AP-913)

- ER Process/Program Coaching & Training

- ER Software Tools Implementation Support

- ER Process: Support, asset criticality determination, PM task/program optimization, CBM program deployment support, risk management process deployment

Monitoring & Diagnostics Centers are crucial to a Reliability Monitoring strategy, enabling plants to:

- Monitor data available at plants

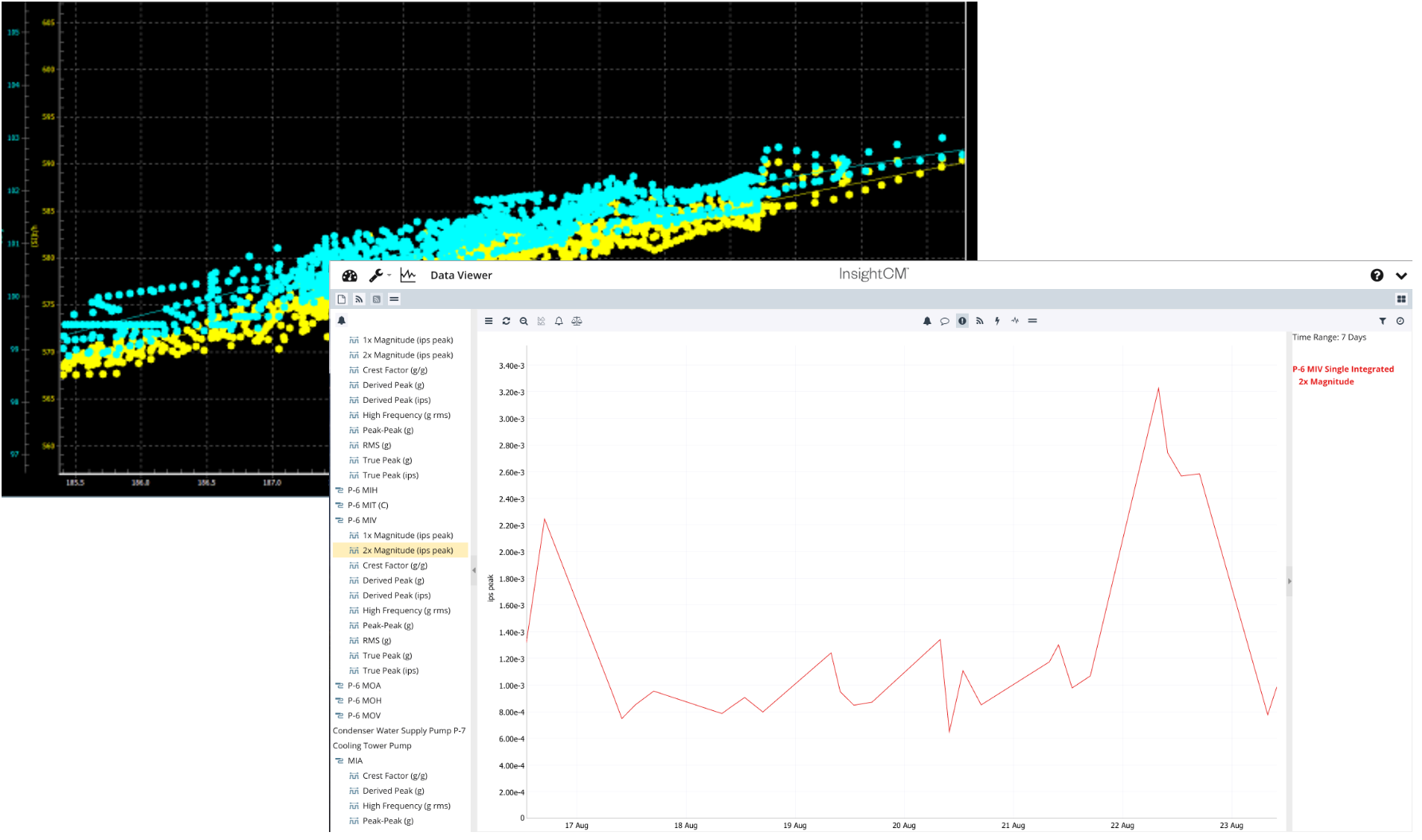

- Utilize Advanced Pattern Recognition (APR) Software: Learning the relationships among process parameters through pattern identification and data training for better data reliability

- Apply Thermal Performance Monitoring: Using existing data to calculate and trend equipment and system performance parameters. A 1% heat rate improvement on a single 500MW unit is worth over $900,000 per year in fuel cost savings

- Detect even small changes and notify plant personnel

- Apply Cutsforth™️ diagnostic models

Through Monitoring & Diagnostics Centers, companies have great access to Continuous On-Line Monitoring (COLM), scoping support & business case development. Cutsforth can facilitate technical steering committees, provide system design support, installation support, commission advanced instrumentation, and integrate these technologies with M&D centers. Using COLM, plants are able to progress using more advanced software programs to best detect and predict failures:

- Level 1: APR application using existing sensors to identify some anomalies

- Level 2: Additional sensors using analysis to improve anomaly detection

- Level 3: Diagnostics utilizing advanced algorithm techniques to diagnose and validate anomalies

- Level 4: Prognostics predicting remaining useful life, while applying AI and prescriptive technologies