Products

InsightCM is Cutsforth’s platform for monitoring solutions. InsightCM is for maintenance professionals who need analytics-based reliability assessment, optimized maintenance schedules, online analysis tools, multiple sensor technology inputs, and connectivity to existing enterprise or IoT software. You can connect your equipment to InsightCM with Cutsforth continuous or wireless monitoring devices to help your maintenance team support predictive maintenance and digital transformation programs.

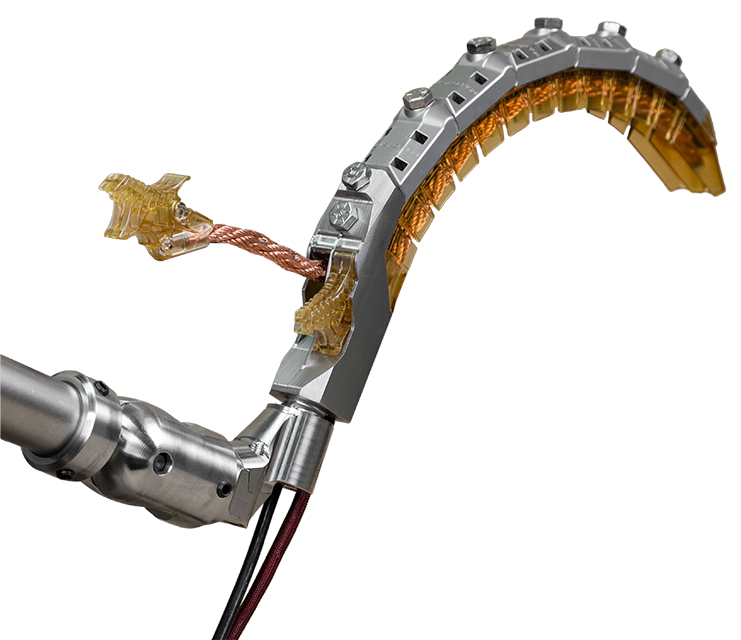

Learn moreSometimes the most challenging maintenance problems are solved by an innovative design solution. That’s the beauty of Cutsforth EASYchange® Removable Carbon Brush Holder—our unique solution to the challenges of brush changing on generators under load. With our removable brush holder system, you can easily reduce the risk of ring fires and forced outages, improve personnel safety, increase reliability, extend collector ring length of service, and reduce routine maintenance costs.

Learn moreSince 2001, Cutsforth™ has installed over 40,000 of the best-in-class EASYchange® brush holders on turbine generators worldwide. Now, with our exclusive EASYchange® Brush Condition Monitoring, Cutsforth™ offers an even better way to operate your generator’s brush-type excitation. Automated measurements and brush health analytics can now be delivered to the control room system and maintenance can be performed based on brush condition, rather than a calendar.

Learn moreCutsforth is recognized by power producers around the world as a leading expert in solving one of the most problematic sources of maintenance: brush excitation maintenance. Our latest line of Cutsforth Shaft Grounding Hardware offers solutions for all types of turbine generators. Cutsforth™ offers two tiers of Shaft Monitoring Systems to best fit the needs of each plant and unit.

Learn moreBy utilizing the patented Cutsforth™ Shaft Grounding Assembly, this system is designed not only to provide the best-in-class ground connection, it also collects, stores and delivers critical voltage information to plant personnel for analysis.

Learn moreThe Assurance System offers an efficient alternative to manual voltage and current measurements with its innovative Assurance System that integrates with most Cutsforth Shaft Grounding Assemblies. The Assurance System takes the readings in real-time and passes them directly to the control room. We’ve included an easy to read display panel for “walk-up” readings. Plant personnel can easily and safely know when changes occur on the shaft; changes that can damage bearings and other generator related elements.

Learn moreThe streamlined user interface displays actionable information for managing the flux conditions for a generator. Variances in the magnetic flux within a generator indicate deterioration of winding insulation. Whether a result of thermal wear, large variation on load, contamination, or other causes, the impact to efficient generation is significant. Imbalances within the rotor can damage insulation, which degrades the generator’s output capacity and increases vibrations. This further damages the insulation leading to a forced outage. But with Cutsforth’s Rotor Flux Monitoring, you can leverage continuous monitoring instead of periodic measurements, saving time and expense.

Learn morePremium Shaft Ground Monitoring and Rotor Flux Monitoring systems can be configured as one powerful Generator Field Monitoring system. By combining the functionality into a single platform, customers can achieve the benefits of both systems in one program integrated into InsightCM™ for better trend data and easier system management.

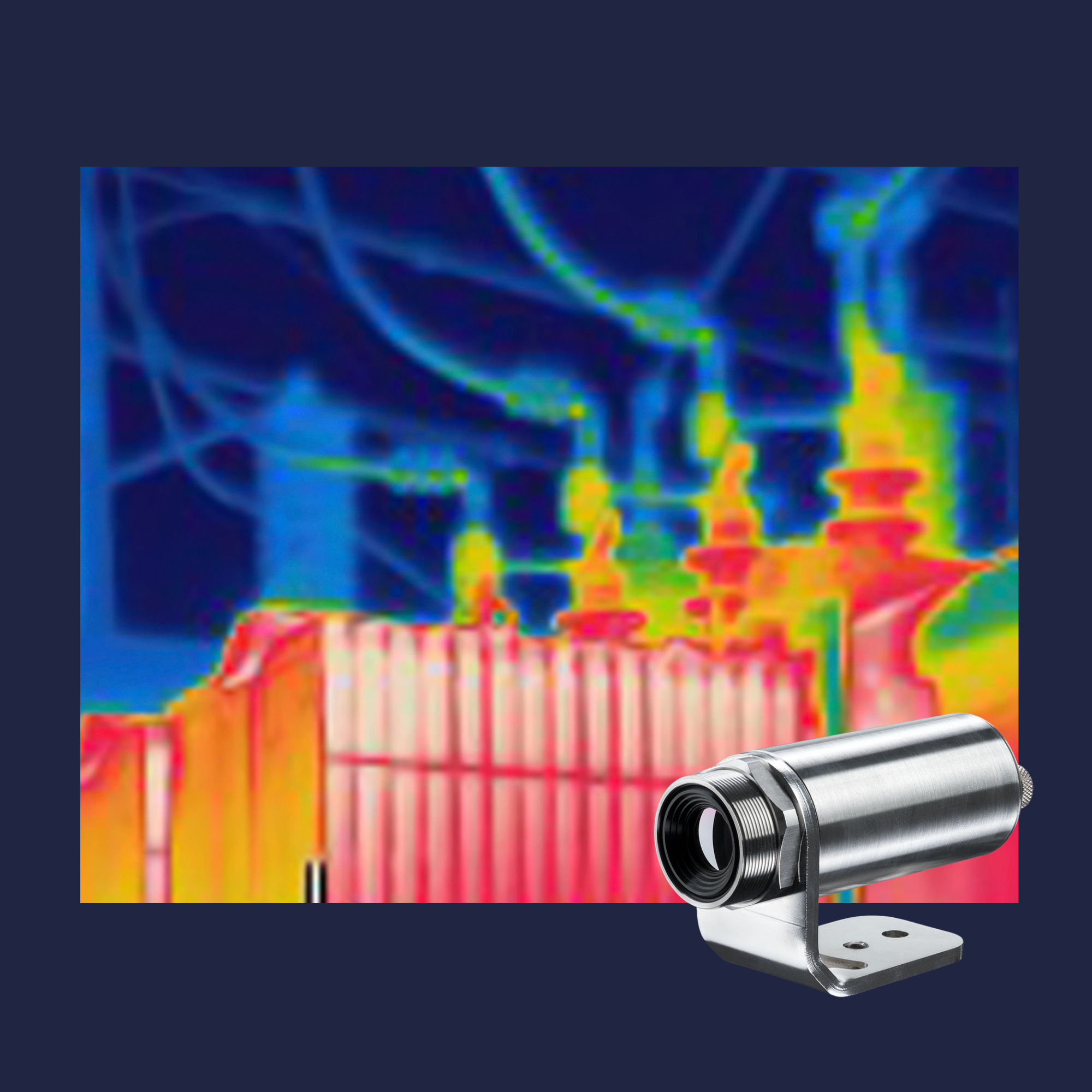

Learn moreMonitoring temperature of assets is a critical maintenance best practice. Constant monitoring of temperature gives insight into the health of an asset over time and catching unexpected rising temperature helps prevent catastrophic failure.

Learn moreCutsforth™ EMI system monitors abnormalities from energized, high voltage assets. It looks for patterns/signatures to indicate potential failures along the generator and out to the IsoPhase Bus. For generators, the EMI Monitoring system is typically configured to monitoring five (5) RF bands that are indicative of components. Alarm levels are set when Power levels within a band exceed a threshold; the thresholds may be configured by the user.

Learn moreCutsforth’s Motor Current Signature Analysis (MCSA) uses voltage and current signals to identify motor faults including rotor-bar damage, misalignment, eccentricity, mechanical looseness, and bearing problems. The MCSA toolkit for InsightCM™ computes features specific to electrical data and motors beyond phasor and waveform analysis.

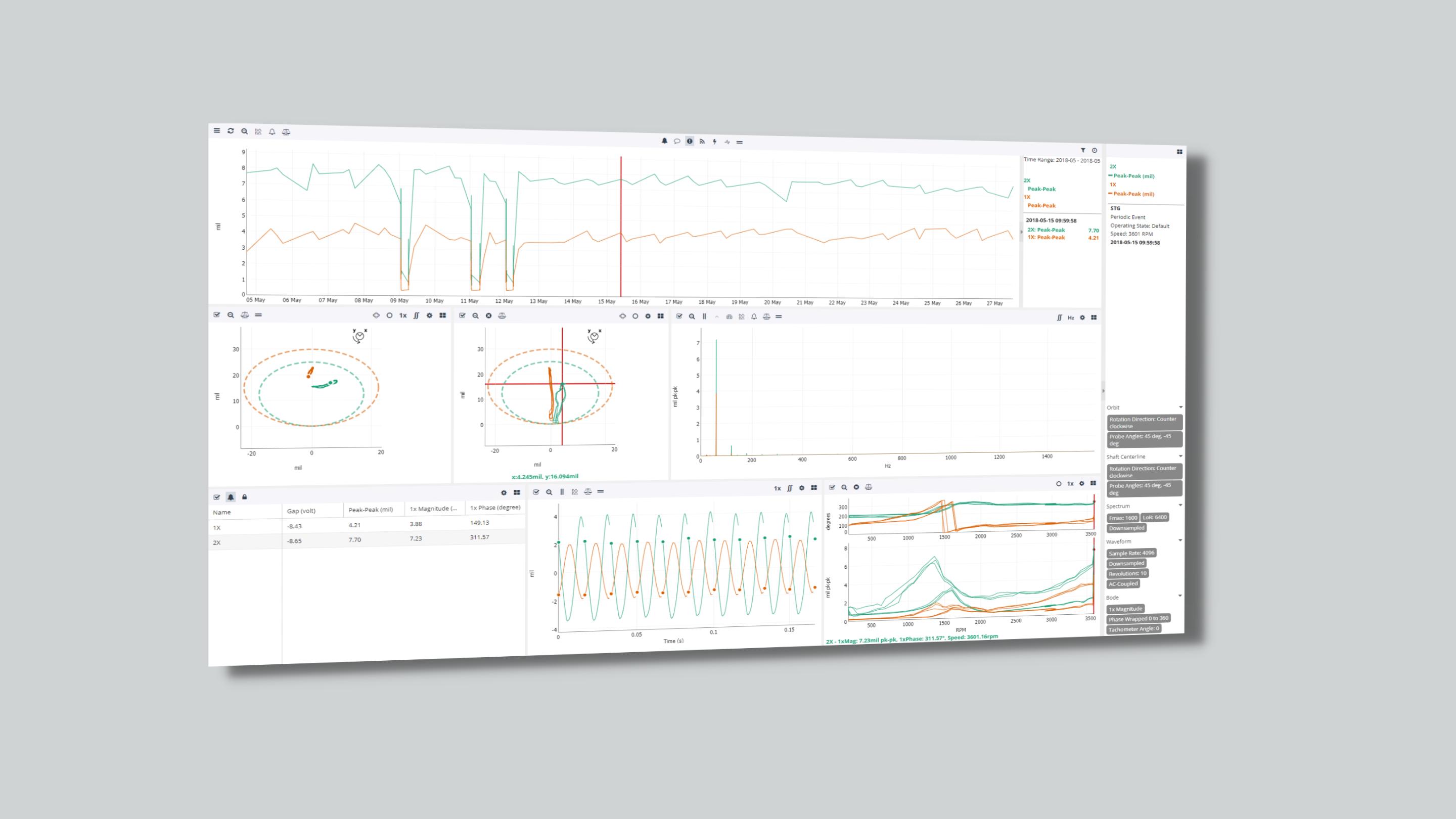

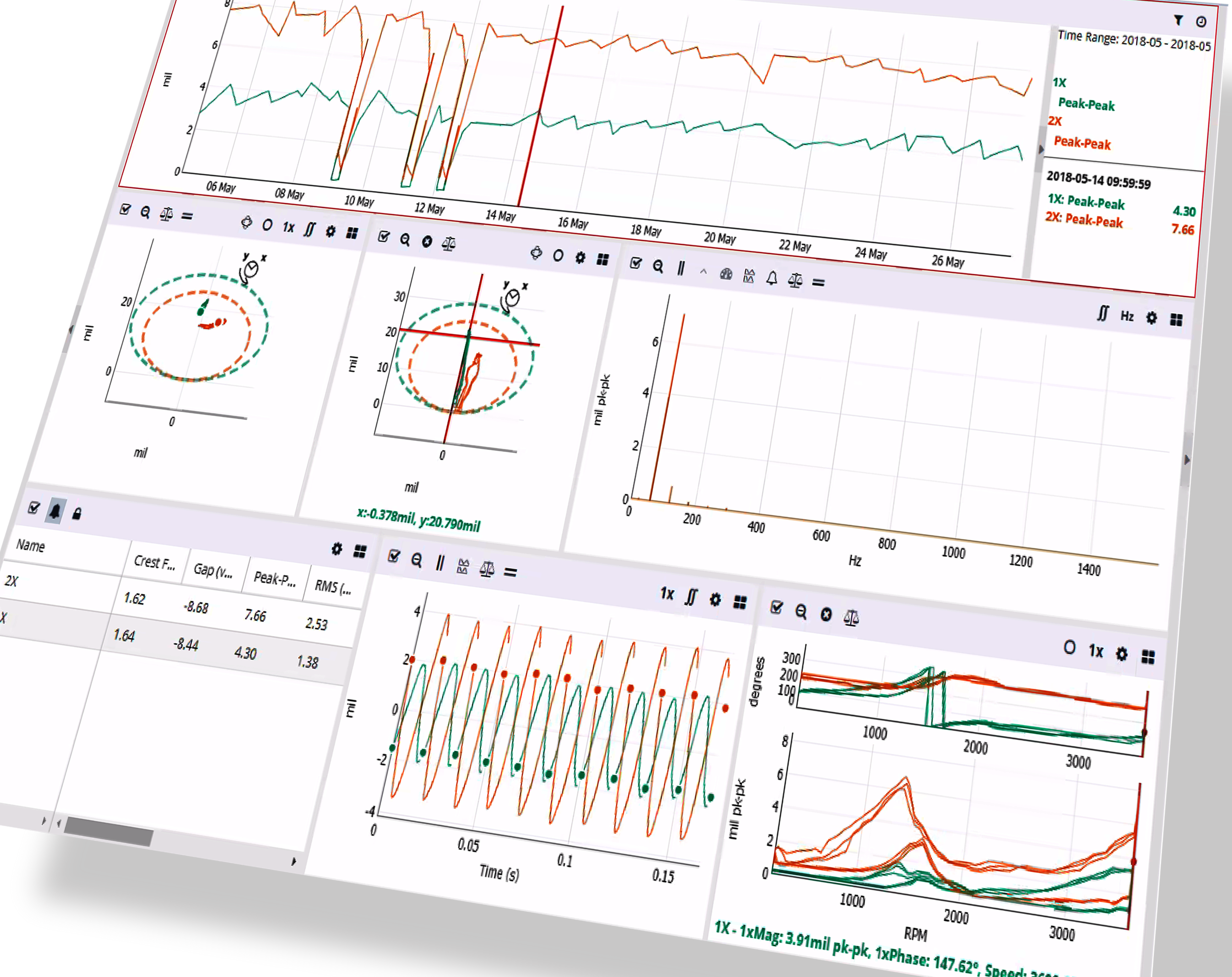

Learn moreVibration Monitoring is a tool to provide early detection of machine failure modes. InsightCM accomplishes this with hardware that monitors equipment 24/7. Alarms and Data Viewers allow a user to quickly identify an issue in order to take corrective action.

Learn more