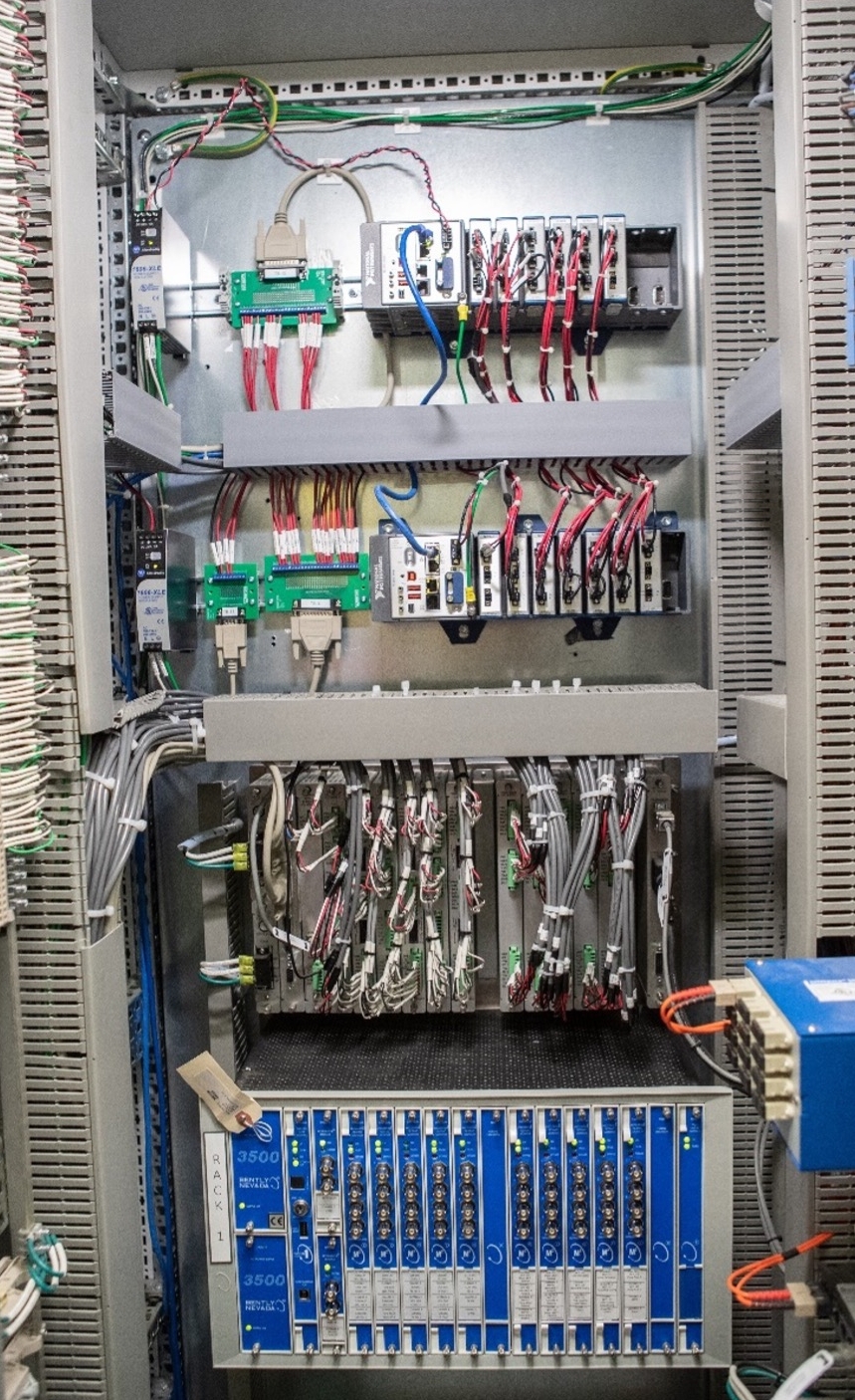

Benefits of Wired Monitoring

• Can work with existing protection systems, where present, or can make direct dynamic measurements using key phasor, tachs, and prox probes

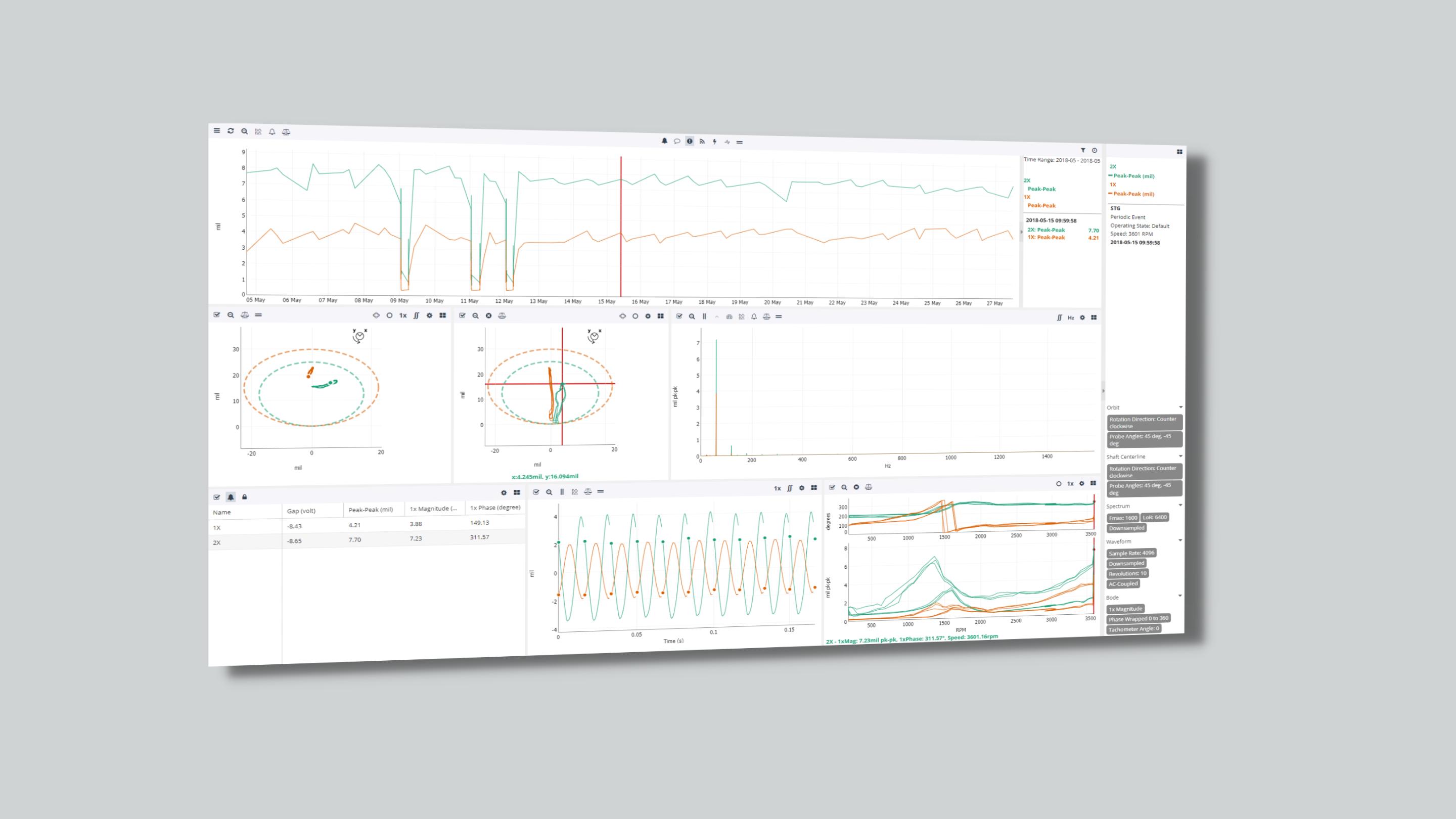

• 24×7 screening to detect alarm events and operating state changes in near real-time

• Intelligent gating, based on a user- configurable operating states and collections parameters, to optimize data volume and coverage

• Ability to stream transient events such as runs up and coast downs

• Can also support process inputs (4-20mA, thermocouple, and more)

Benefits of Wireless Monitoring

• Replace manual route collections

• Lower installation cost

• Same Data Viewers as Wired Monitoring Systems

Wired monitoring systems provide 24×7 monitoring and support event based data capture based on:

Time—Data is captured in user-configurable time intervals such as once an hour, once a day, three times a day, and so on. Choose when to capture the features calculated (less data), the full waveform (more data), or both.

Change in engineering units (delta EU)—Data is captured when a calculated feature changes by the set delta value with respect to the initial measured value. Once the trigger condition is met, the trigger resets from the latest value but retains the same delta limit. This feature is most often used for ramp-ups and coast-downs, during which data recordings at periodic rotational speeds are desired; for example, recording a 4 s waveform every 50 rpm during ramp-up.

Alarm limits—Data is captured when a measured feature crosses a preset limit. You must acknowledge alarms before retriggering.

Force trigger—You can request a real-time reading using the force trigger option in the action menu for any device. This feature is good for troubleshooting sensor connections, spot-checking an asset, or investigating the current state before acknowledging an alarm.

Wireless monitoring devices dramatically reduce retrofit installation costs, when battery powered, by eliminating the need for running cable and conduit for signal, power, and ethernet. InsightCM™ supports two different platforms for wireless sensors. The first is NI’s platform which provides a wireless measurement device and wireless vibration sensor, both for vibration, along with their matching gateway. The second is Erbessd’s wireless sensors and matching gateway. Both platforms are based on Bluetooth Low Energy Version 5 (BLE5).

Learn More about Wireless Monitoring