magnetic

Interference

(EMI) Monitoring

Overview

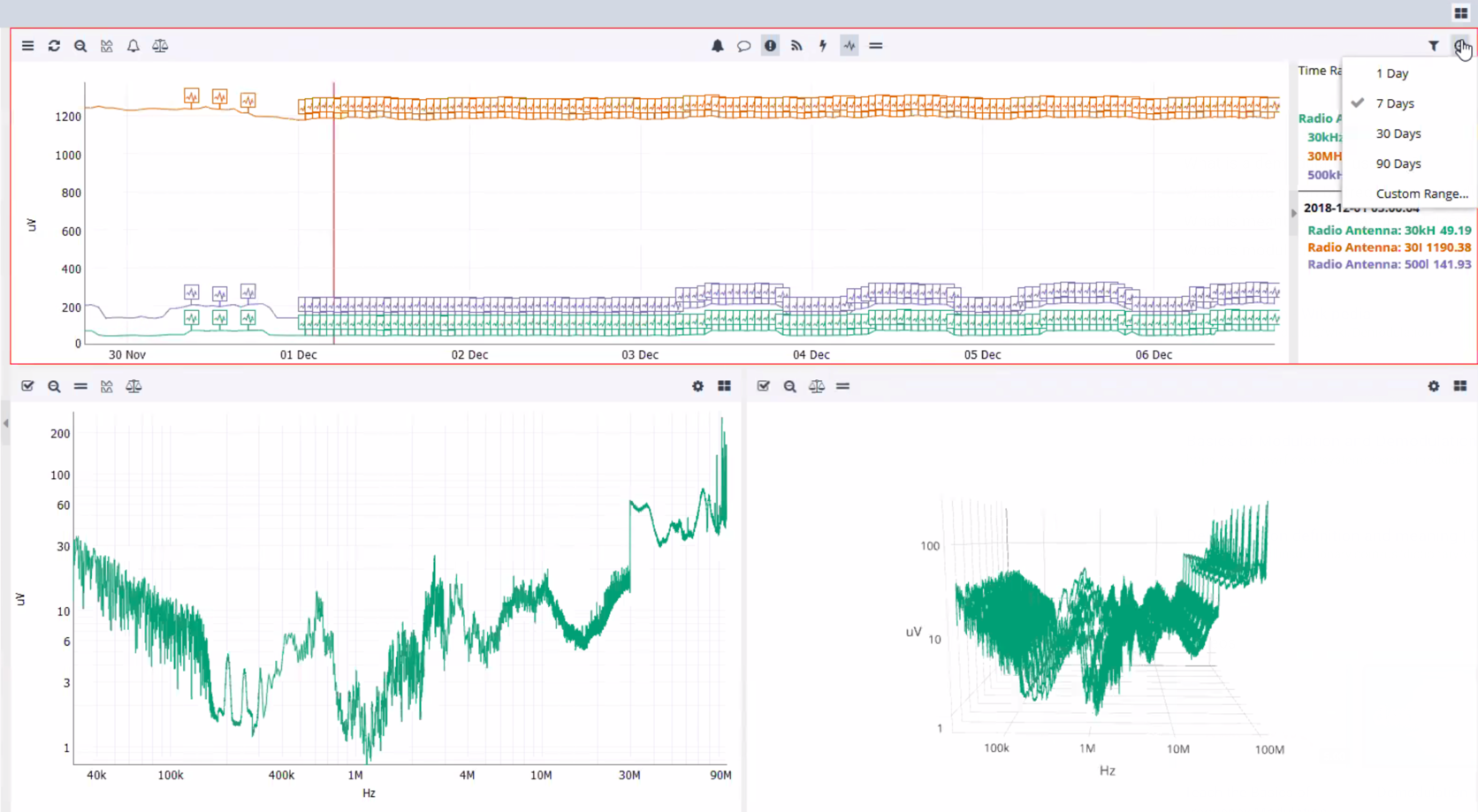

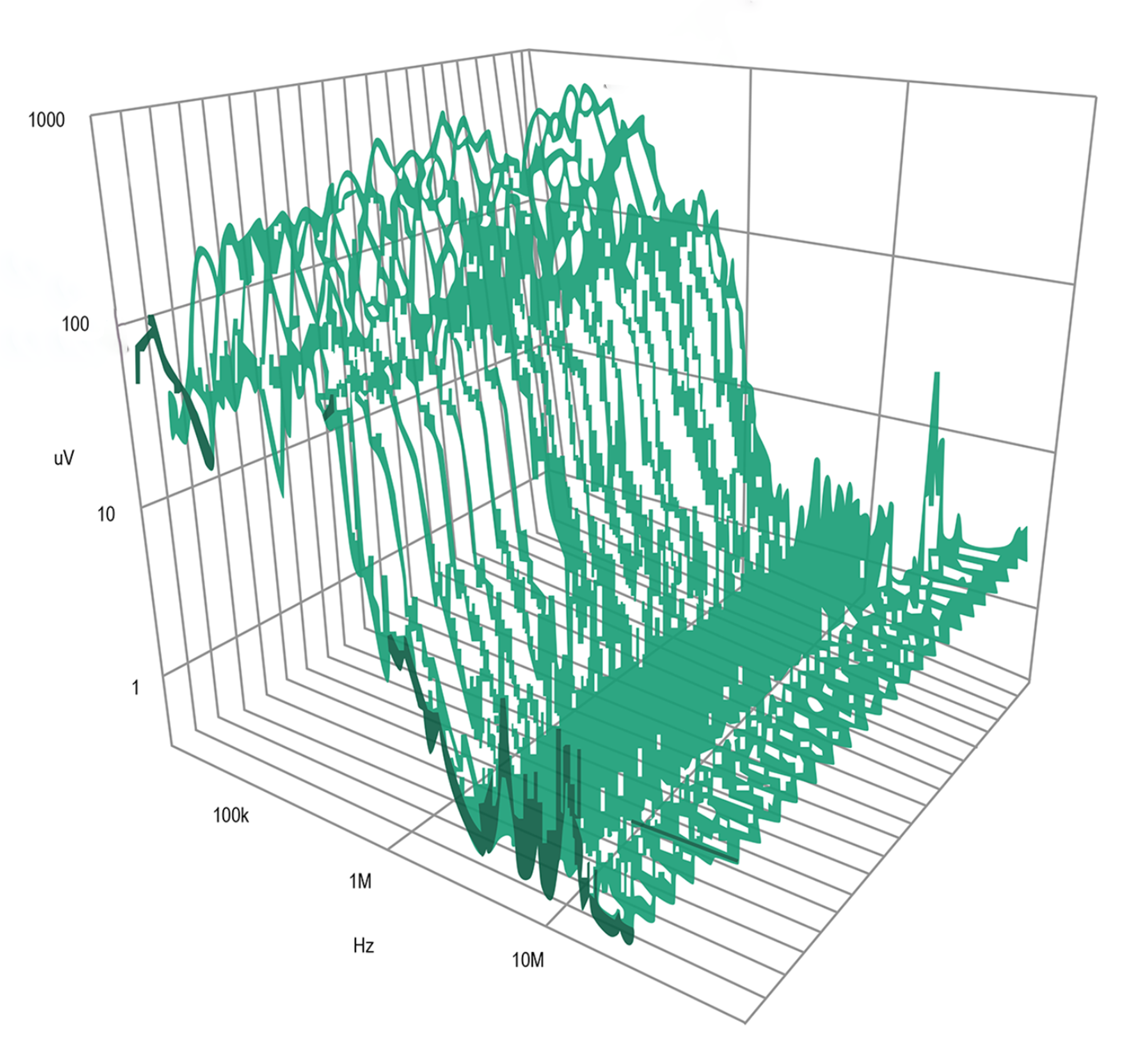

For generators, the EMI Monitoring system is typically configured to monitoring five (5) RF bands that are indicative of components. Alarm levels are set when Power levels within a band exceed a threshold; the thresholds may be configured by the user.

EMI Monitoring is able to maximize the early detection of EM emissions to predict failures including:

- Arcing

- Coronal Discharges

- Gap Discharges

- Partial Discharges

- Sparking

Current Transformers are typically coupled around the Generator to Neutral Ground connection, although it alternatively could be coupled around a frame ground. The System is easy to install and does not require an outage, or insertion of any probes or couplers into the generator or transformer.

Generators

-

Band 1: Exciter and Collector

(typically set 30kHz to 500kHz) -

Band 2: Stator Core and Slots area

(typically set 500kHz to 5 MHz -

Band 3: End Windings

(typically set 5 MHz to 30 MHz) -

Band 4: Isophase Bus or other connections

(typically set 30 MHz to 100 MHz) -

Band 5: Total Power Band to compare generator noise to overall system noise

Transformers

-

Single Total Power Band: Compares total power of the Transformer with the total power of the Generator

Thresholds are User Defined and set in Microvolts (uV). Typically, 3 levels are used.

- Below 1000 uV—no issues present

- Between 1000 uV and 10,000 uV — growing issue that demands observation

- Above 10,000 uV—remedial action required

System Features

- Multiple RFCT (Radio Frequency Current Transformer)

- All Components necessary to install

- Supports Coaxial runs up to 200 feet

- One InsightCMTM license

- Support from Subject Matter Experts

Benefits

The EMI Monitoring system offers a cost-effective alternative to traditional methods of failure detection. When compared with traditional methods, Cutsforth™ EMI Monitoring offers the following benefits:

- Lower Costs

- Multiple Component Measurements within a single system:

- EMI Monitoring measures stator and end-windings and Isophase Bus with a single system rather than multiple systems using invasive couplers and probes

- Holistic view of the generator and auxiliary equipment health in one application

- Non-invasive installation, NO outage required