Key Features

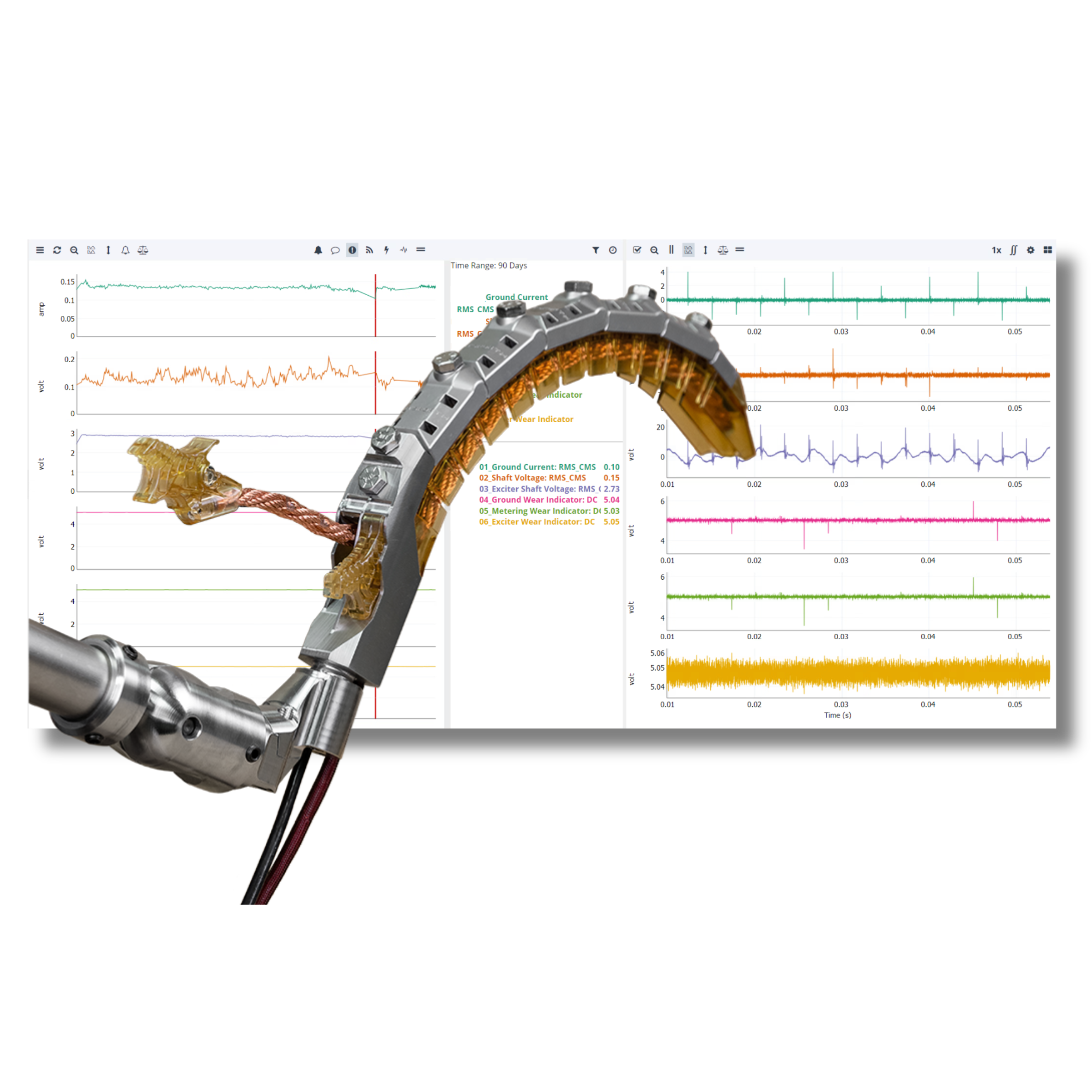

- Continuously measures Shaft Voltage and Current for early detection of failures such as:

- Poor Shaft Contact

- Bearing Failure

- Stator Insulation Failure

- Exciter Insulation Failure

- Ground Neutral Failure

- Touch Screen Monitor for real time information display

- Lengthens time between maintenance outages

More Features

- USB port enables data download for analysis or the installation of upgrades and revisions

- Delivers waveform level data of critical shaft grounding elements

- Rope Alarm indicates when ground and metering ropes require replacement

- Multi Channel 4-20 mA outputs allows communication to plant DCS systems

- The system is fully managed and data is archived using InsightCM™

Our expert field techs will come to your site to install the shaft grounding system.

The connection arms and ground rope holders will be installed first. Then, the technician will connect the hardware system to the Cutsforth Shaft Ground Premium monitoring system, located near the grounding connection point. Before leaving the site, our technicians will ensure data is flowing from the grounding hardware into the Cutsforth InsightCM software.

Once installation is complete, our team will setup the InsightCM software appropriately for your equipment. Our support team is always ready for any questions you have about the system or the data you’re seeing.

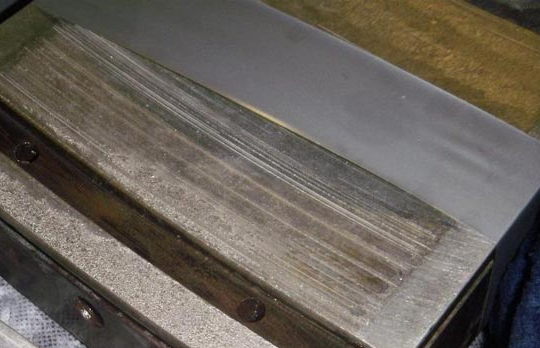

When generator shafts are not grounded correctly, the stray voltages will still find a path to ground. Most often, this path is through bearings, leading to very extensive, and expensive, damage. These pictures are just a few examples of the damages we’ve seen in the field.

By monitoring the shaft ground voltage and current, you can detect problems as they develop and address them early, avoiding these costly repairs, unnecessary downtime, and extended outages.

Contact Us TodayContinuous monitoring of shaft voltage and current reduces operating costs. Plants are able to reduce both the risk of component failures that lead to unplanned outages, and the risk of injury to maintenance personnel. Condition based monitoring allows you to predict failures and plan accordingly giving plants more control over the outage cycle. Monitoring allows plants to optimize capital spending, allocating manpower and financial resources when and where necessary.

By implementing these predictive maintenance practices related to shaft grounding, asset owners can continue to run their systems with confidence knowing what they’re up against during the next maintenance outage.

Download Paper