Condition Monitoring

Monitors, Trends, and Archives

- Usable Brush Length (%)

- Brush Vibration (Mils Displacement, Pk-to-Pk)

- Temperature (degrees)

Configurable Brush Health Alerts

- Brush Length Warnings

- High Vibration

- High Temperature

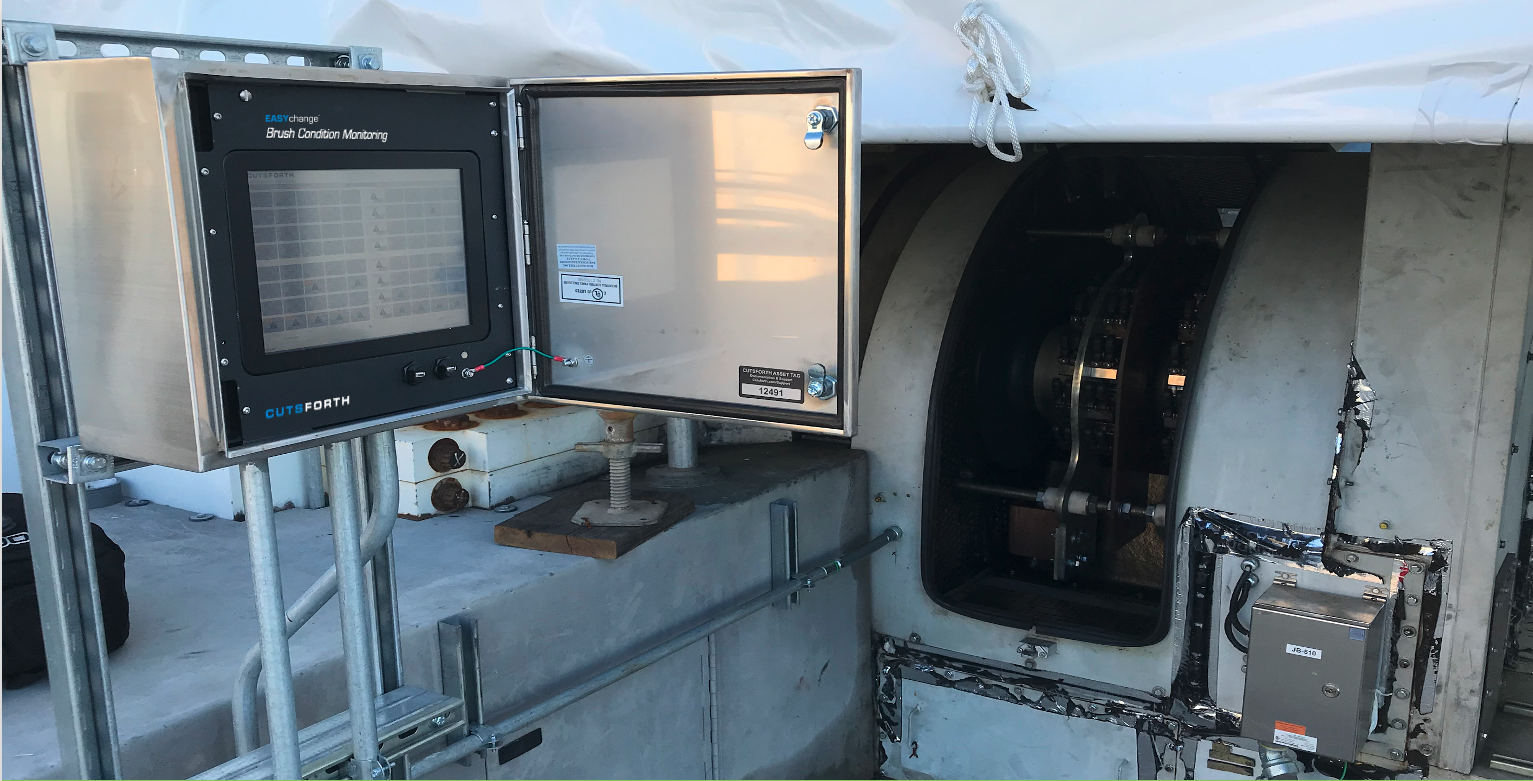

Since 2001, Cutsforth™ has installed over 40,000 of the best-in-class EASYchange® brush holders on turbine generators worldwide. Now, with our exclusive EASYchange® Brush Condition Monitoring, Cutsforth™ offers an even better way to operate your generator’s brush-type excitation. Automated measurements and brush health analytics can now be delivered to the control room system and maintenance can be performed based on brush condition, rather than a calendar.

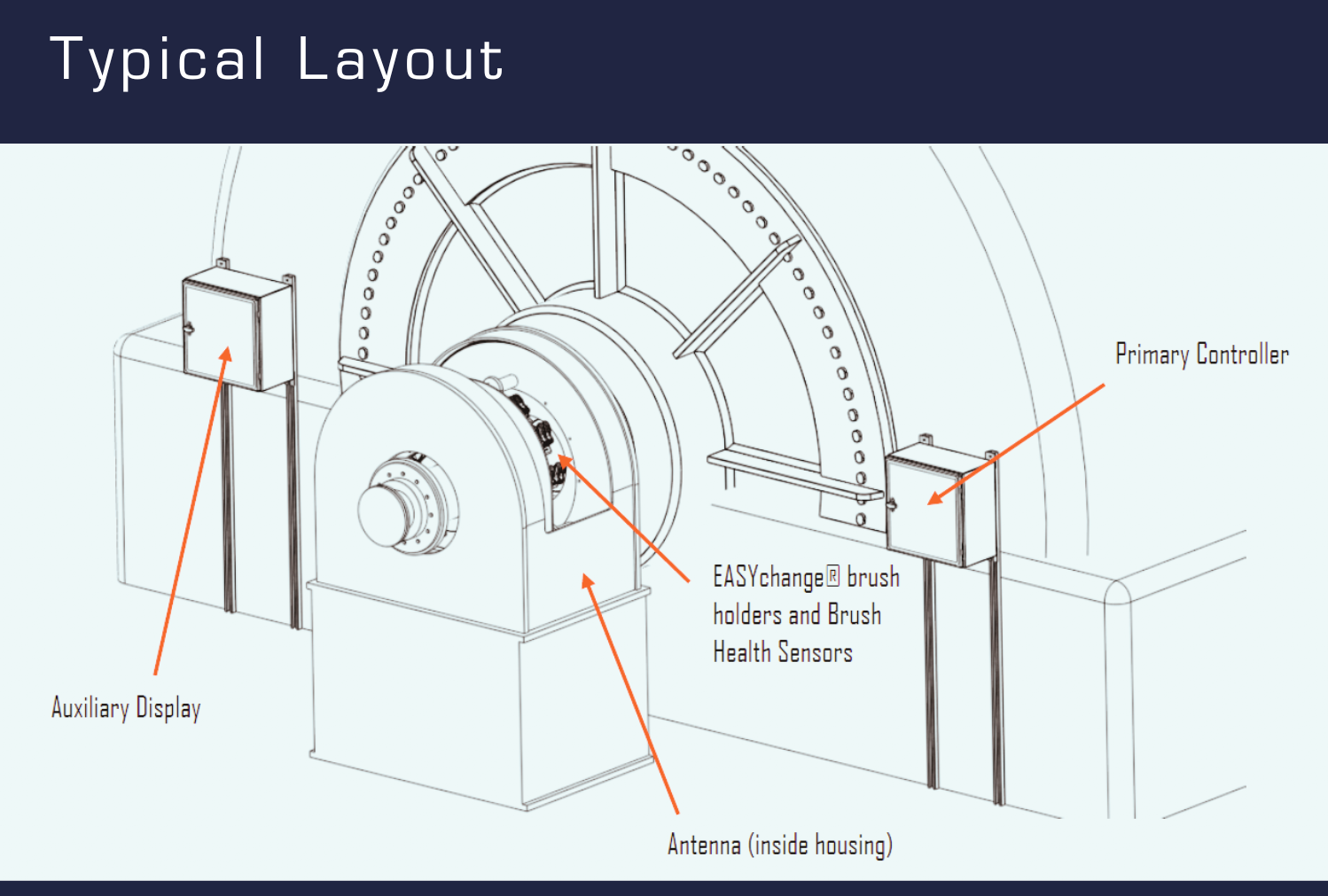

The Brush Condition Monitoring System is composed of the Brush Health Sensor (BHS), a Cutsforth™ developed industrial data logger, and a System Controller equipped with a touch-screen interface that compiles data collected from several BHS units installed with the EASYchange® brush holders.

Concerned about needing to replace the BHS battery down the road? Our quality batteries integrate with our Brush Health Sensor and the sensor is integrated with the spring. When a new battery is eventually needed, follow these simple instructions for replacing the spring.

Learn more about our Brush HoldersAt the generator, the System Controller’s touchscreen user interface visually alerts users of short brushes and high vibrations, both based on plant defined thresholds. Each data square represents an individual brush, providing relevant data and critical threshold warnings.

This same critical data can also be relayed to the control room, your data historian, or InsightCM system, reducing the number of unnecessary physical inspections.

For quick reference, brush health historical analytics are logged by the system and available on the Brush Detail screen for each brush holder location.

Trending brush health analytics improves operator efficiencies and optimizes a plant’s staff utilization. This greatly reduces operating expenses and forced outages resulting from catastrophic events such as ring fires and flashovers.

How would BCM integrate into your plant’s equipment? We’ve got you covered. Cutsforth works with your plant to install our Brush Condition Monitoring systems in a large variety of layout scenarios. Our skilled install team will come to your site to install the system, providing a turnkey experience.

Consider integrating our Auxiliary Display for convenient access to brush health readings on both sides of your equipment.

Explore the latest techniques and technologies to trend and monitor usable brush length and vibration. Our expert speakers will present use cases from the field, providing real-world examples of how these techniques have been successfully applied. You’ll learn about the benefits of Brush Condition Monitoring, including early detection of potential issues and improved equipment performance.