Rotor Flux Monitoring

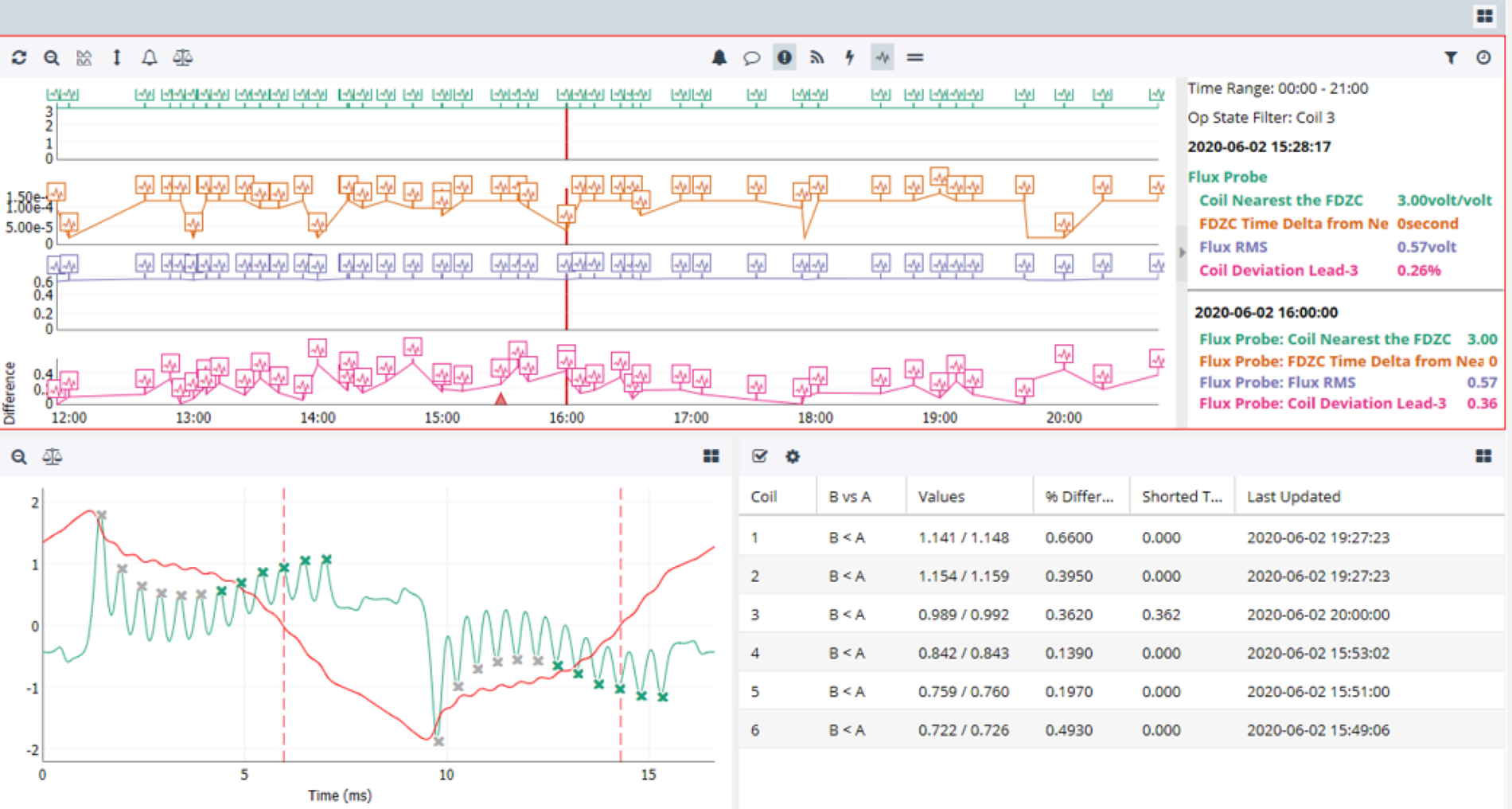

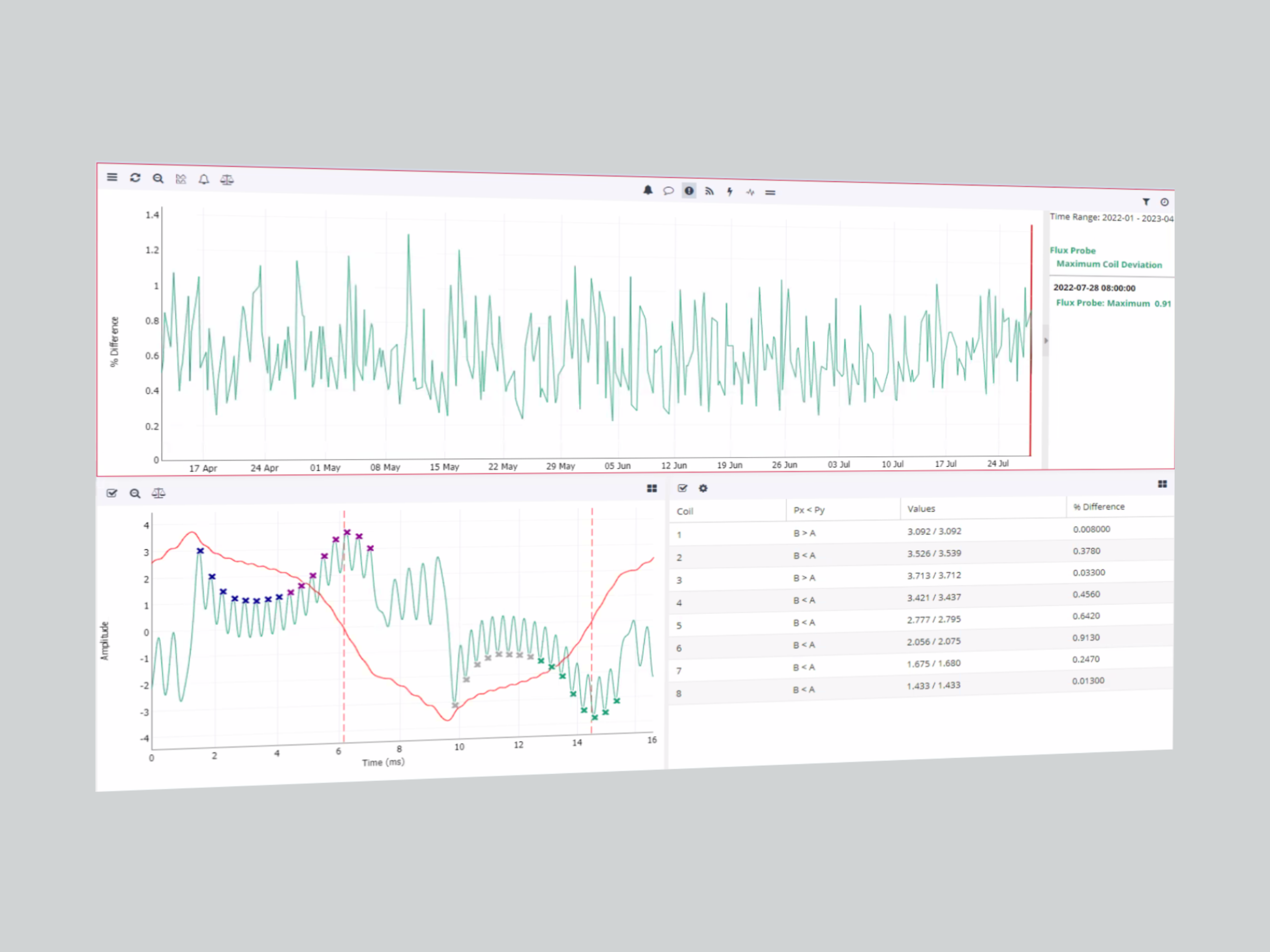

Straightforward user interface displays all the actionable information required to effectively manage the flux conditions on a generator.

Overview

Variances in the magnetic flux within a generator indicate deterioration of winding insulation. Whether a result of thermal wear, large variation on load, contamination, or other causes, the impact to efficient generation is significant. Imbalances within the rotor can damage insulation, which degrades the generator’s output capacity and increases vibrations. This further damages the insulation leading to a forced outage.

Benefits of Rotor Flux Monitoring System

Continuous monitoring is better than periodic measurements

Benefits

- Plants own and control their own data

- Eliminates annual outsource expenses—one less vendor onsite, saving costs

- Real time information

- Real time status alarms—multiple parameter alarms

- Easy to Install and Does Not Require an Outage

Performs Analysis: Automated Cycle Finding (Two-Pole Machines)

- High speed samples identify shorted turns and flux density zero cross (FDZC)

- Flux waveforms and generator loads are archived for historical trend analysis

- Waveforms are collected periodically

- Data sets are collected using three dimensions: Time (periodically), Alarms, and when FDZC crosses a coil

User-Defined Thresholds for

Alarm Levels

- Alarms can be associated with multiple features

- Full data sets are collected on alarms

- Operating states can be configured using InsightCM

Calculations

- Maximum flux deviation

- The percent deviation associated with an FDZC

- A table calculates deviation and number of shorted turns per coil

on FDZC. These values are trended over time - System plots FDZC for each coil over time

- System Approximates Shorted Turns on Accessible Coils

Creates a Generator Health Trend

- Critical for identification of worsening shorts indexed against time and changing load conditions

- Featured trends provide early indication conditions leading to rotor

ground faults - Manage the maintenance cycle through real – time measurements

Return on Investment

Is degradation of the rotor windings within your generators placing your operation at risk?

Take four minutes to read our paper to discover how continuous online monitoring of the rotor field is crucial to your generator’s health.

Download Paper

Declaration of Conformity