Implementing Predictive and Prescriptive Digital Pump Maintenance Technologies

Pumps play a vital role in process industries including chemicals, oil and gas, mining, water treatment and power generation. When pumps degrade in availability or performance due to a developing defect, production losses are experienced in downtime, performance losses and quality.

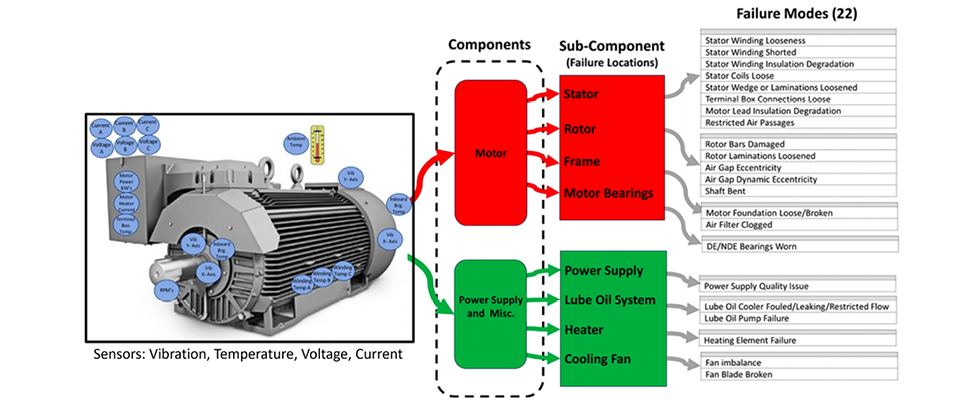

Pumps and systems are monitored in this digital era with a wide range of sensors to detect probable pump defects, automate analytics and recommend mitigating actions. Automating sensor data collection and analytics improves worker productivity by focusing the workforce on tasks that require human insight and decision-making. With automated sensor systems, benefits are accrued like lower maintenance costs, increased equipment life span, lower capital costs, increased production output, improved sustainability, reduction in safety incidents and improved visibility of pump health and performance.

This article will focus on the components of a digital predictive and prescriptive maintenance program and application. It will also describe the process of implementation and share a case study.

Read the rest of the article at Pumps&Systems.com – https://www.pumpsandsystems.com/implementing-predictive-prescriptive-digital-pump-maintenance-technologies