Electrical Signal Analysis (ESA)

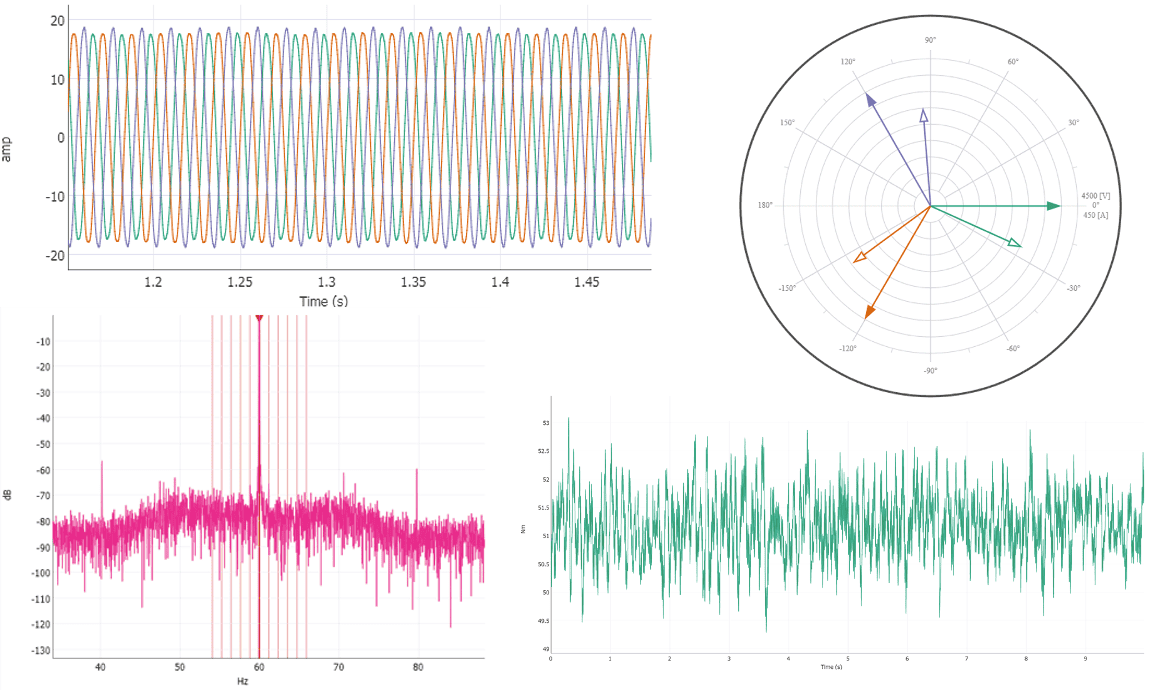

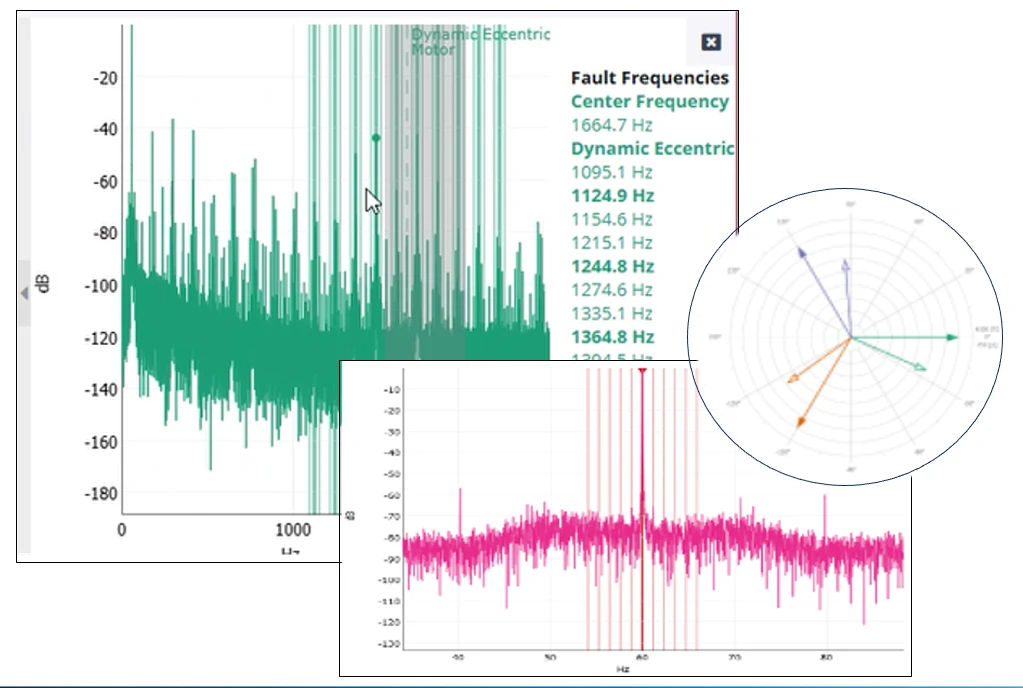

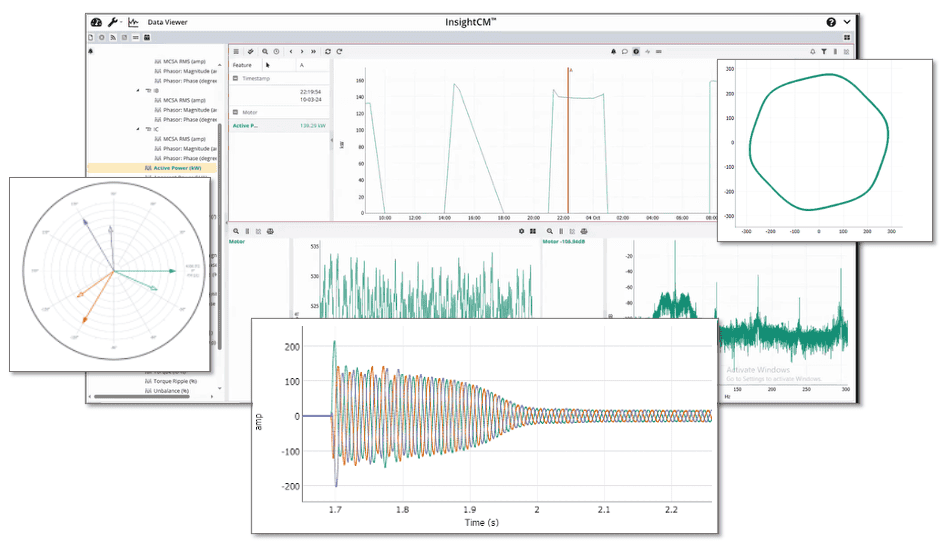

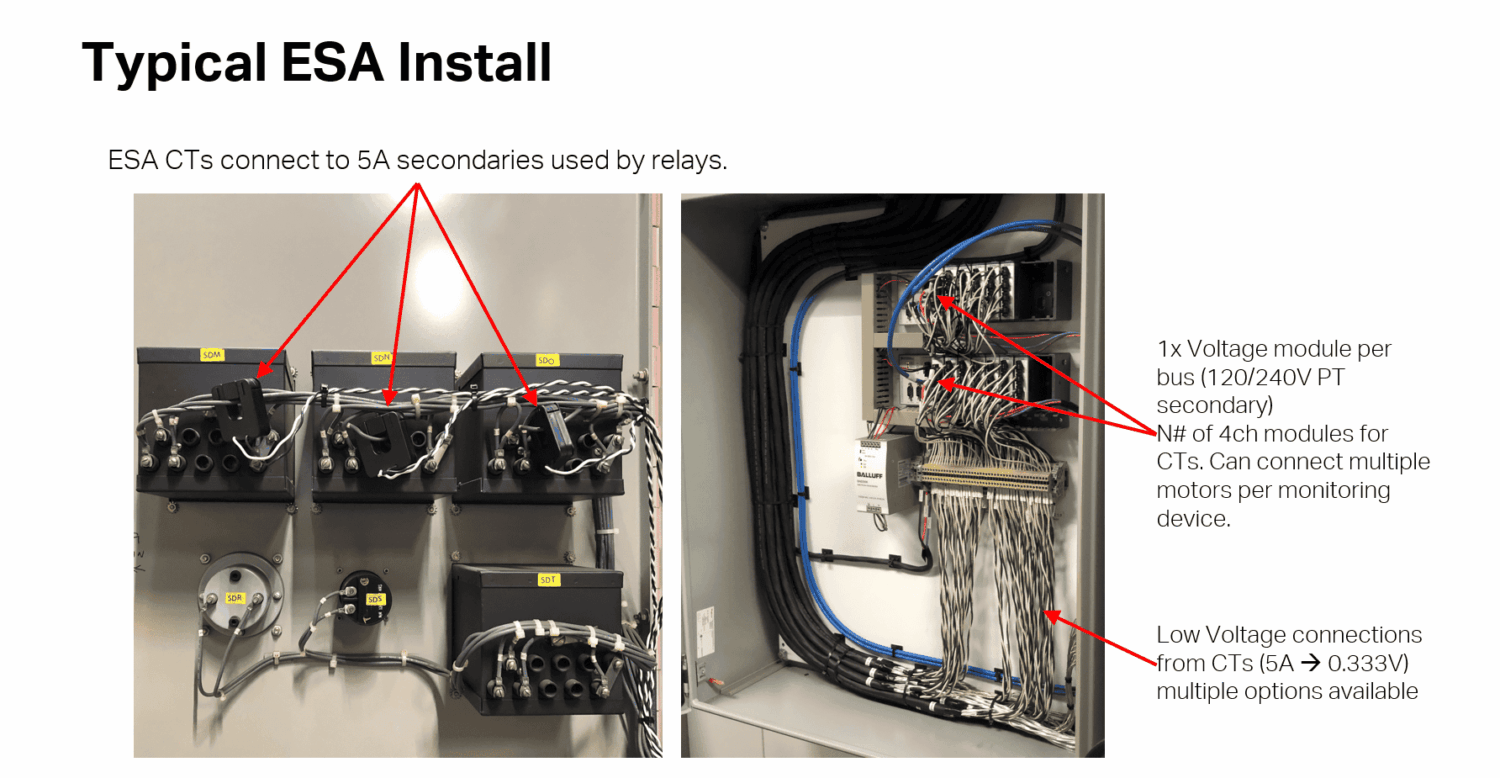

ESA measures 3-phase current and voltage signals from fixed- and variable-speed motors to detect subtle changes that reveal developing equipment faults. By analyzing variations in these signals, it can identify issues such as insulation breakdown, rotor bar defects, or load imbalances long before failure occurs. This non-intrusive method leverages existing electrical circuits to provide continuous, cost-effective monitoring that delivers early warning of both electrical and mechanical problems — offering a powerful, scalable way to improve reliability and reduce unplanned downtime.