Generator Brush Condition Monitoring

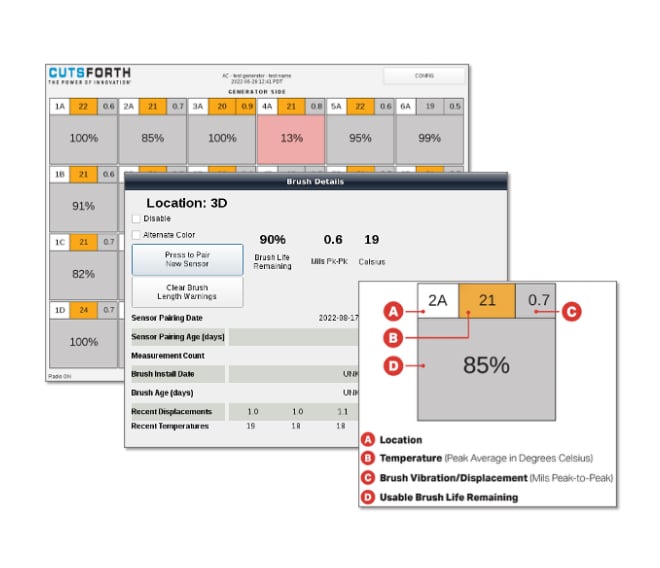

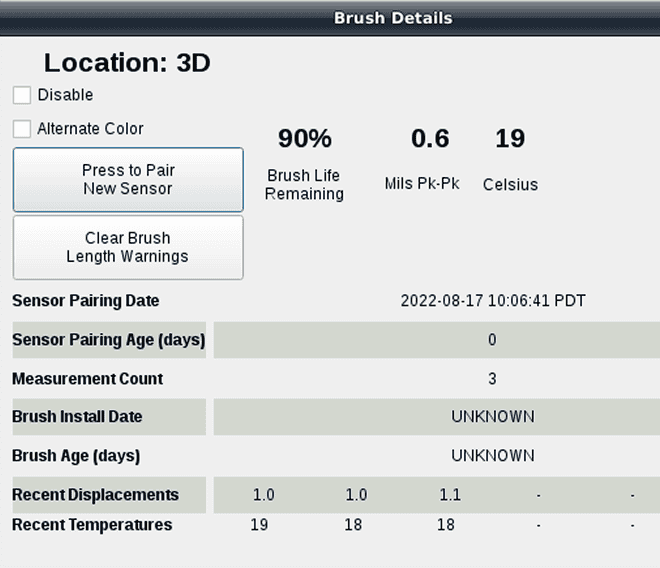

Brush condition monitoring (BCM) continuously tracks the health and performance of brushes and slip rings to prevent costly wear-related failures. By monitoring parameters such as usable brush length, temperature, and brush vibration, operators can detect abnormal wear, arcing, or loss of contact pressure before they cause catastrophic failure . This proactive approach increases reliability, extends maintenance intervals, and enhances operator safety by reducing manual inspections and amount of time in and around energized and rotating equipment. Supports NFPA 70B/70E compliance through multiphysics monitoring and documented condition data.