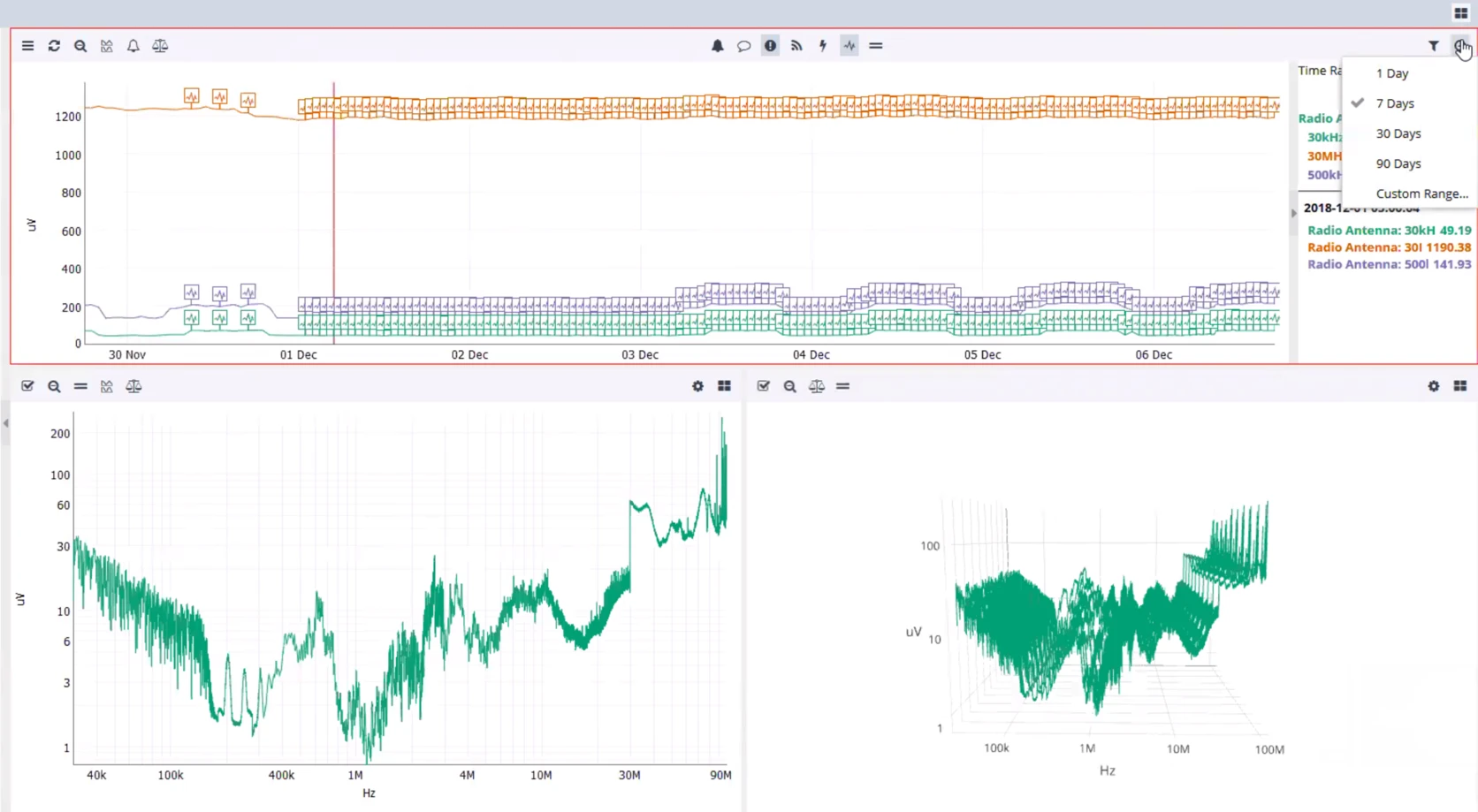

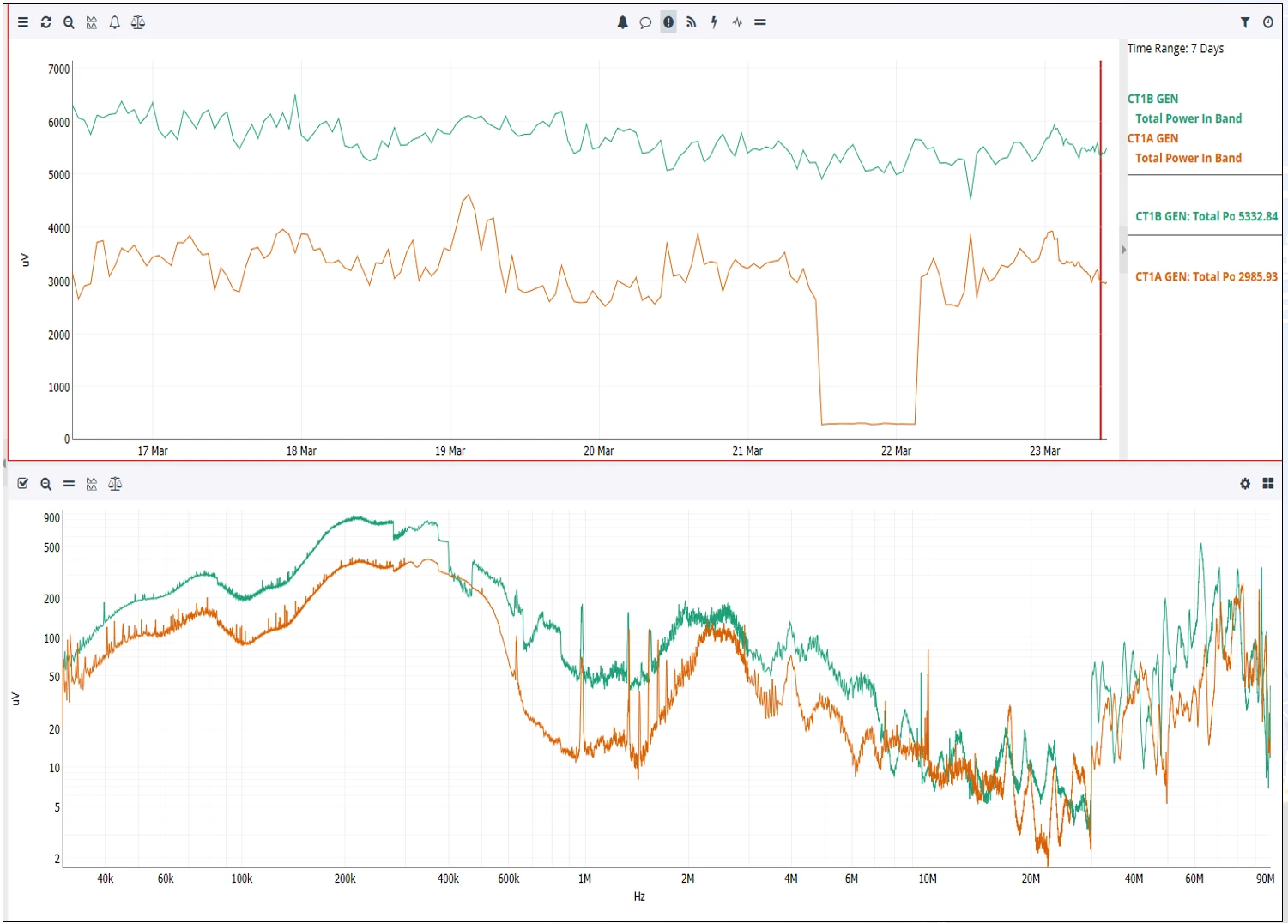

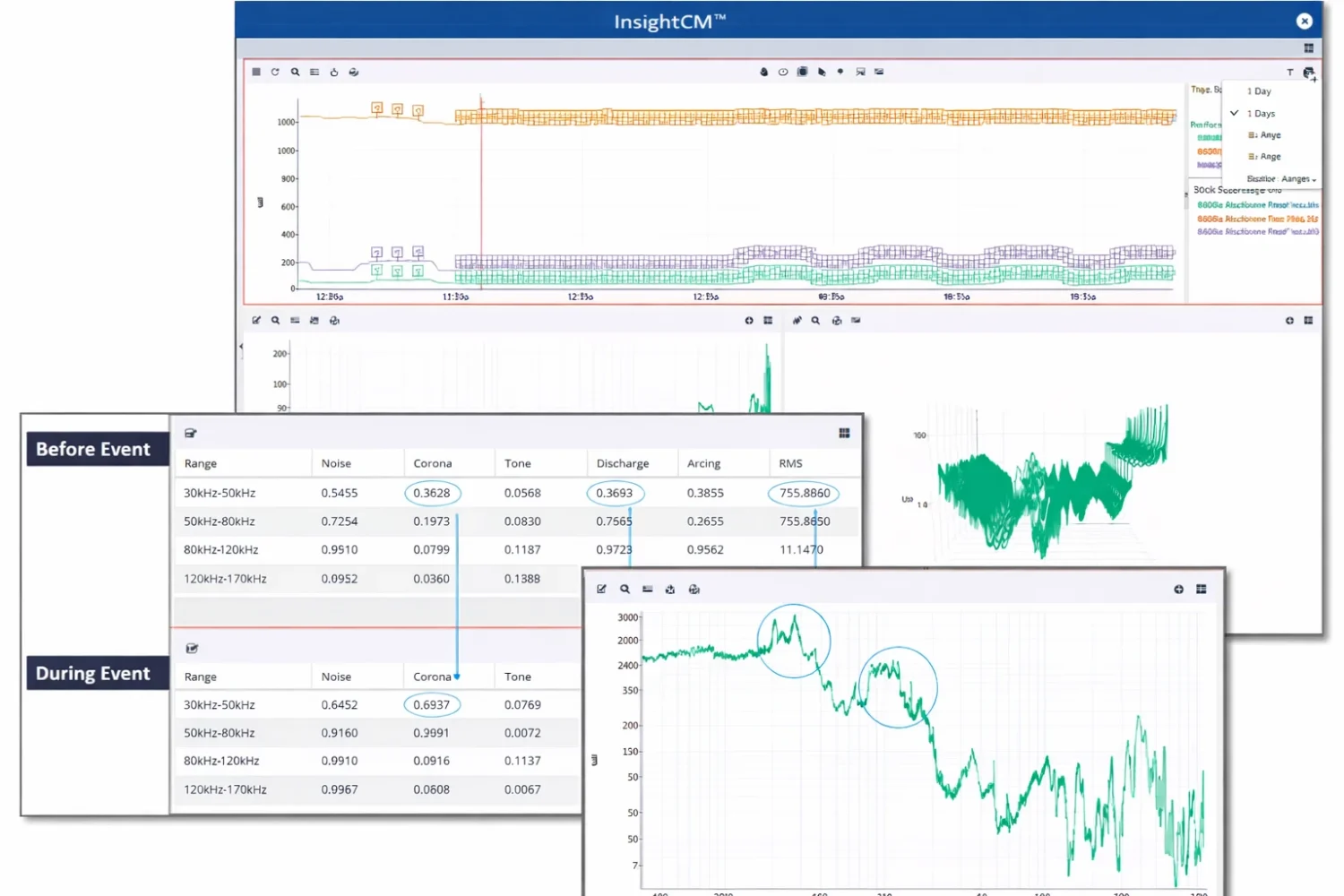

Electromagnetic Interference (EMI) Monitoring

EMI monitoring detects high-frequency emissions produced by electrical activity such as arcing, corona, discharge, or partial discharge in machines and power systems. By capturing and analyzing these transient signals, EMI provides an early warning of insulation degradation, loose connections, and other electrical faults that traditional vibration or thermal methods may miss. It’s a fast, non-contact, highly sensitive technique that helps identify developing issues long before visible or thermal symptoms appear.