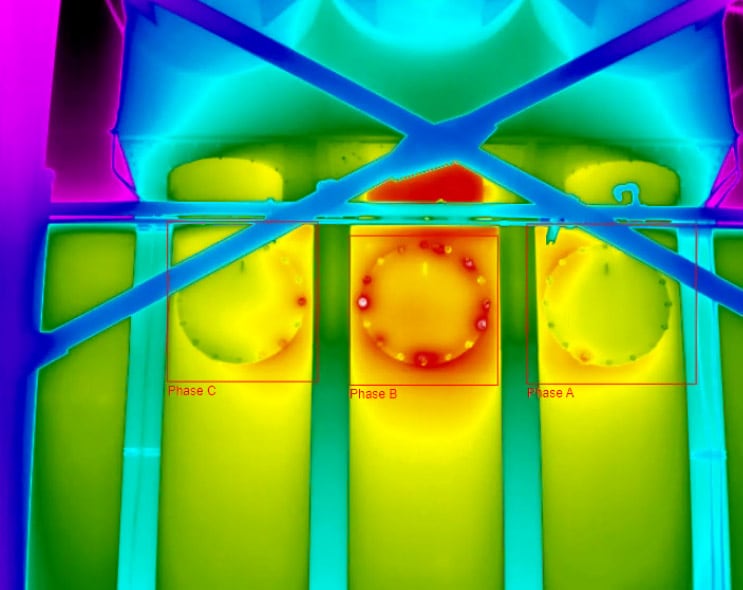

Infrared (IR) Thermography

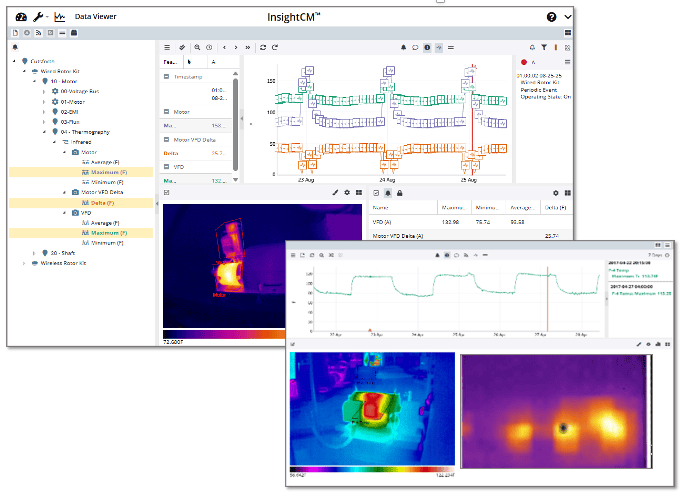

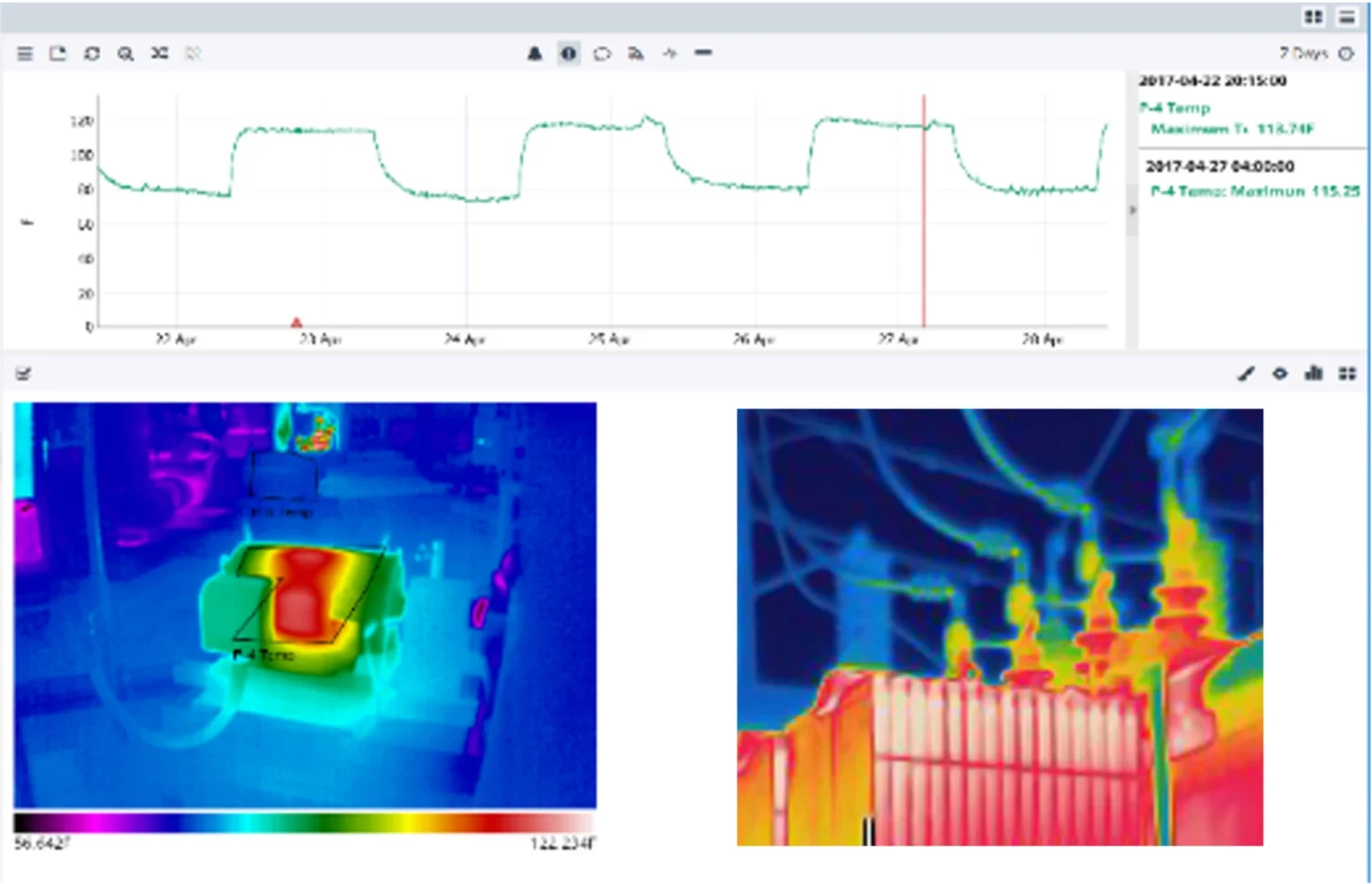

IR thermography uses thermal imaging to detect heat patterns that reveal developing problems in electrical and mechanical equipment. By visualizing surface temperature changes, it helps identify loose connections, overloads, friction, and insulation breakdown before they escalate into failures. As a non-contact, real-time technique, thermography is a powerful tool for continuous or periodic condition monitoring — especially when safety or accessibility limits the use of other sensors.