Our Standard Measurement Capabilities

Every plant has unique monitoring needs. InsightCM makes it possible to add specialized sensors and measurements to capture the right data for complex conditions and expand coverage as your strategy evolves.

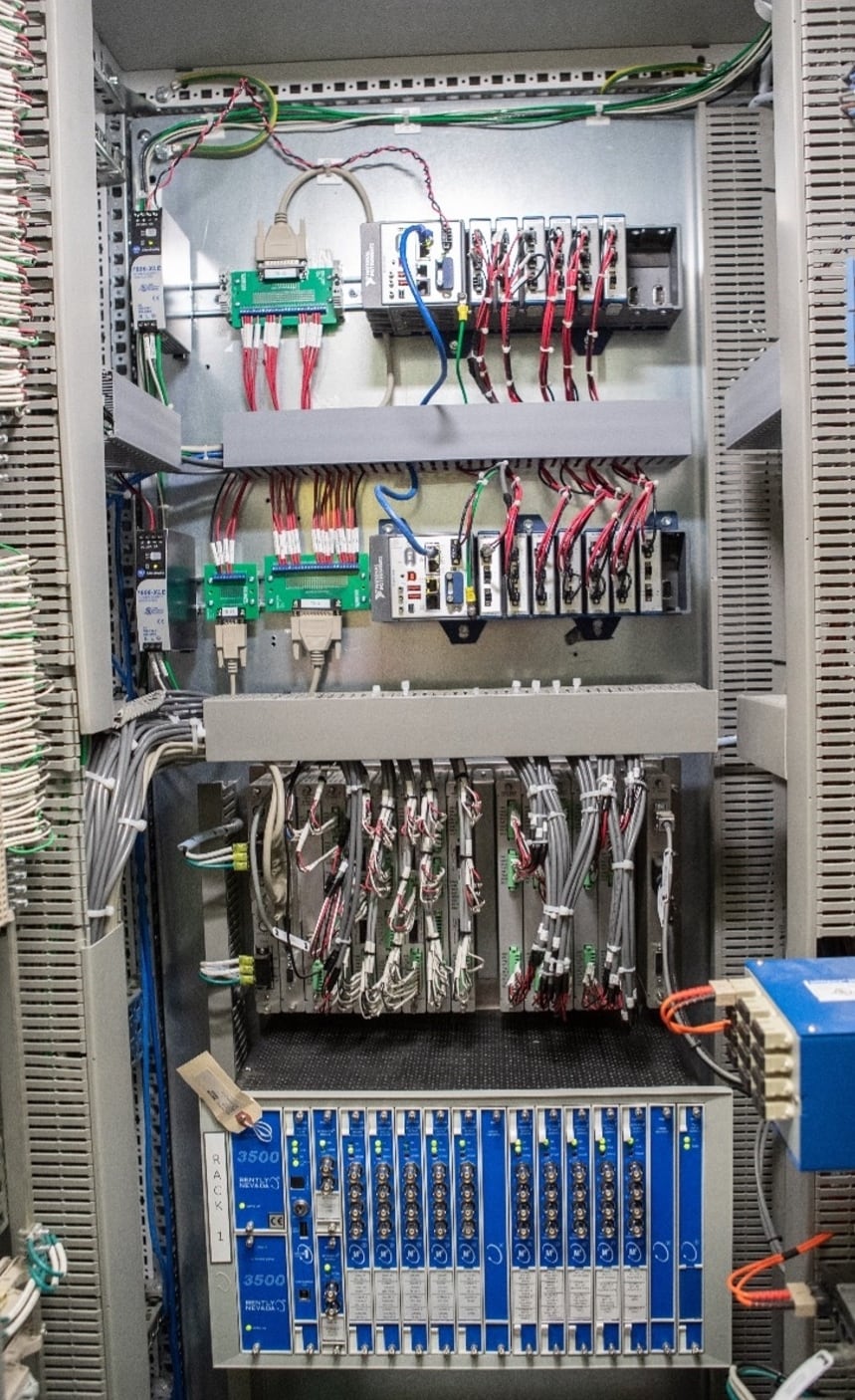

Cutsforth monitoring systems unify wired and wireless sensing into one powerful platform, capturing vibration, electrical, thermal, and oil analysis data with exceptional clarity. With high-resolution converters, fast sampling, and long waveform capture, our measurement hardware delivers the performance needed to uncover subtle changes before they become failures.