Vibration Analysis

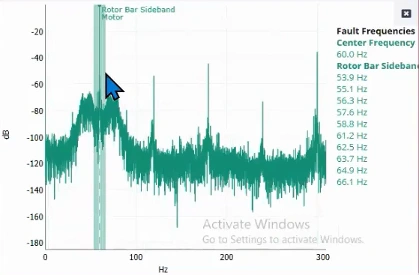

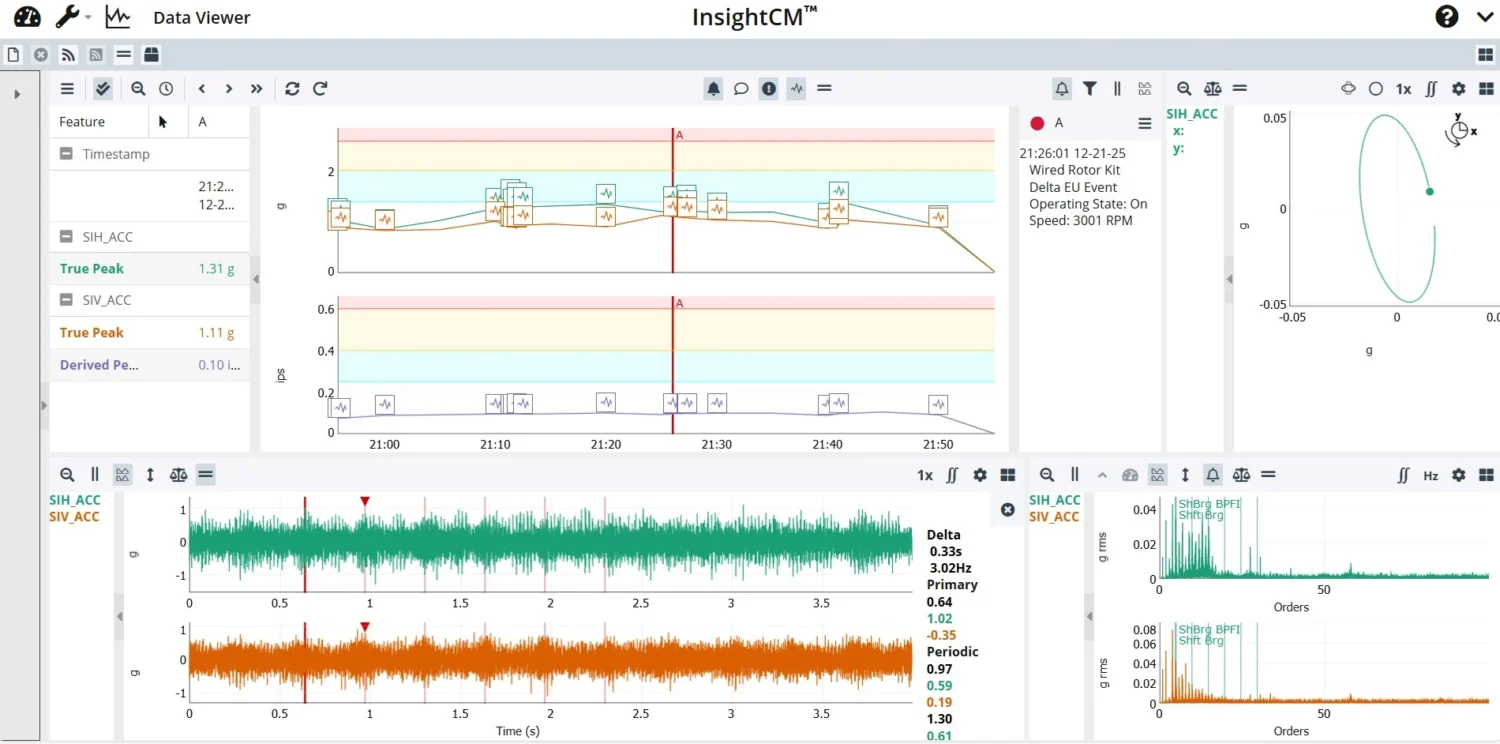

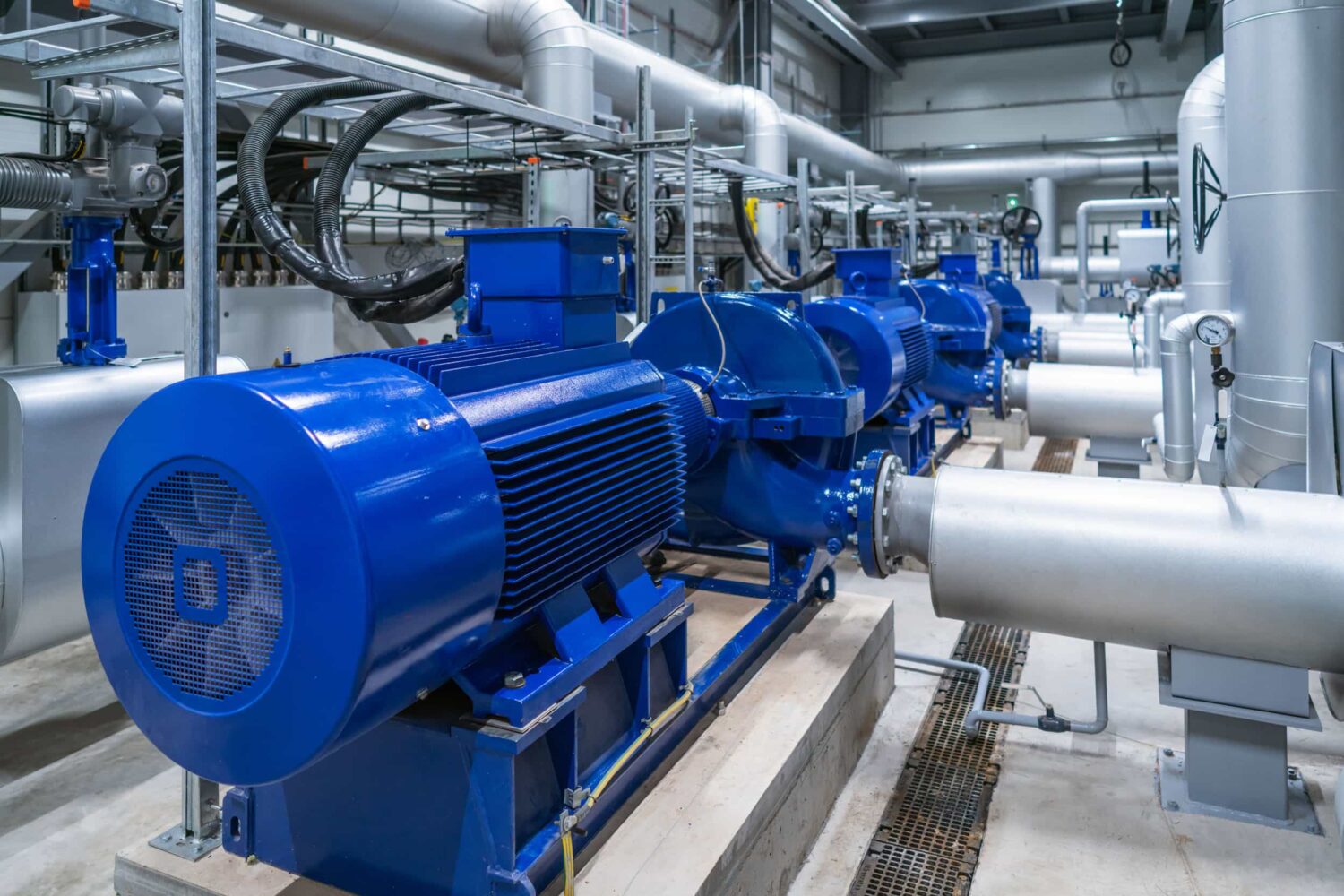

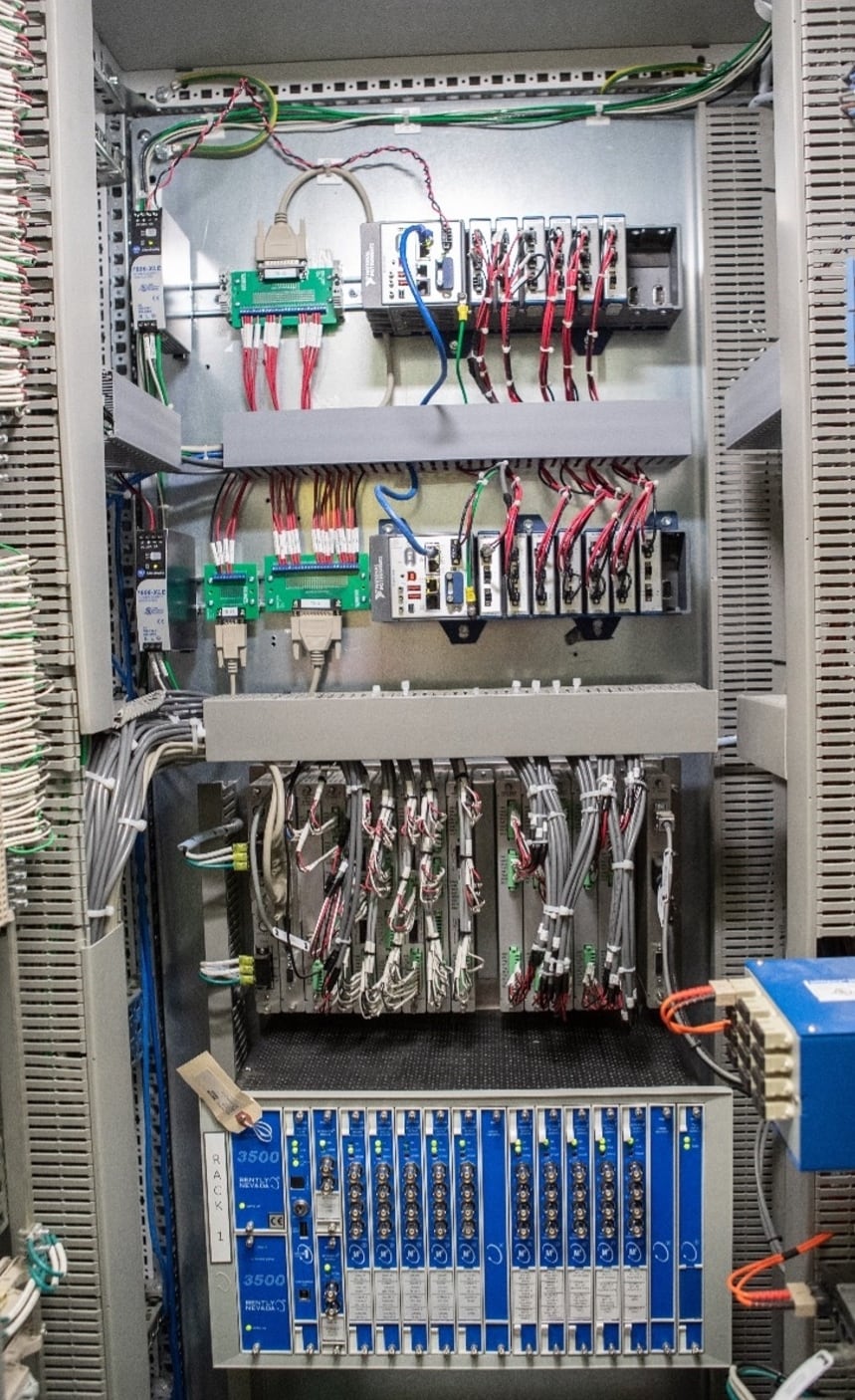

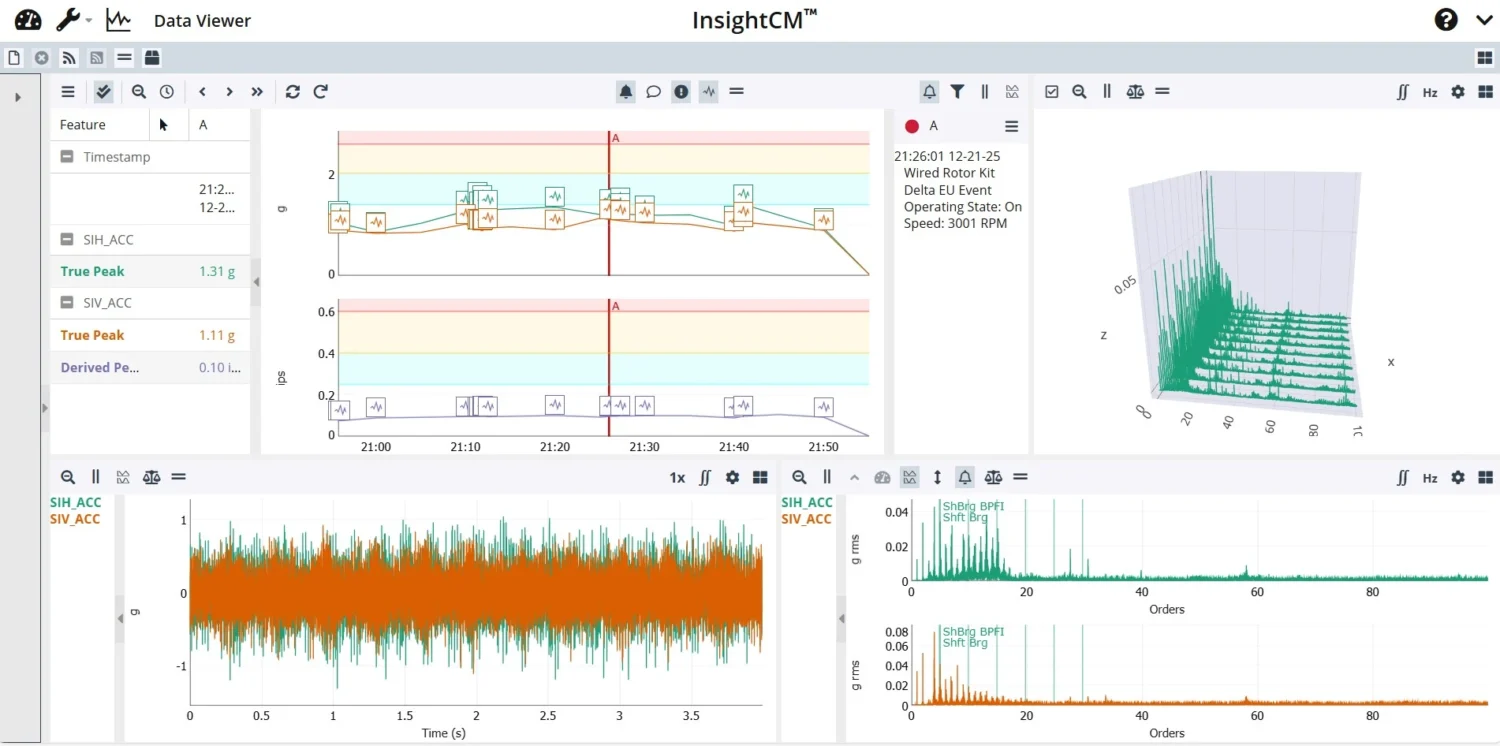

Vibration monitoring measures the motion and dynamic behavior of rotating and reciprocating equipment to detect developing mechanical faults. By analyzing vibration amplitude, frequency, and patterns over time, it reveals imbalance, misalignment, bearing wear, looseness, and other issues that compromise reliability. As one of the most proven and widely used condition monitoring methods, vibration analysis provides continuous, high-fidelity insight into machine health and performance.