Critical Asset Monitoring with VDMS

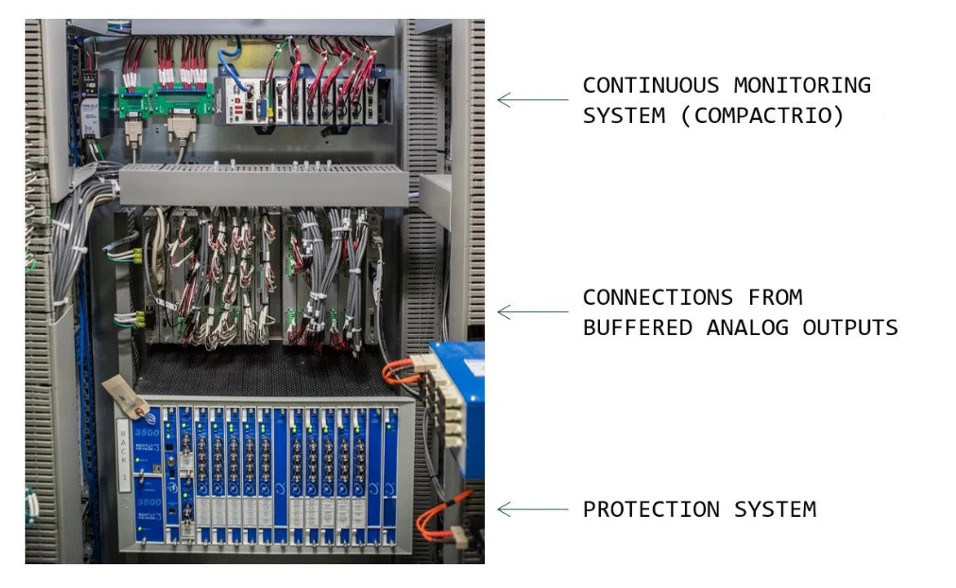

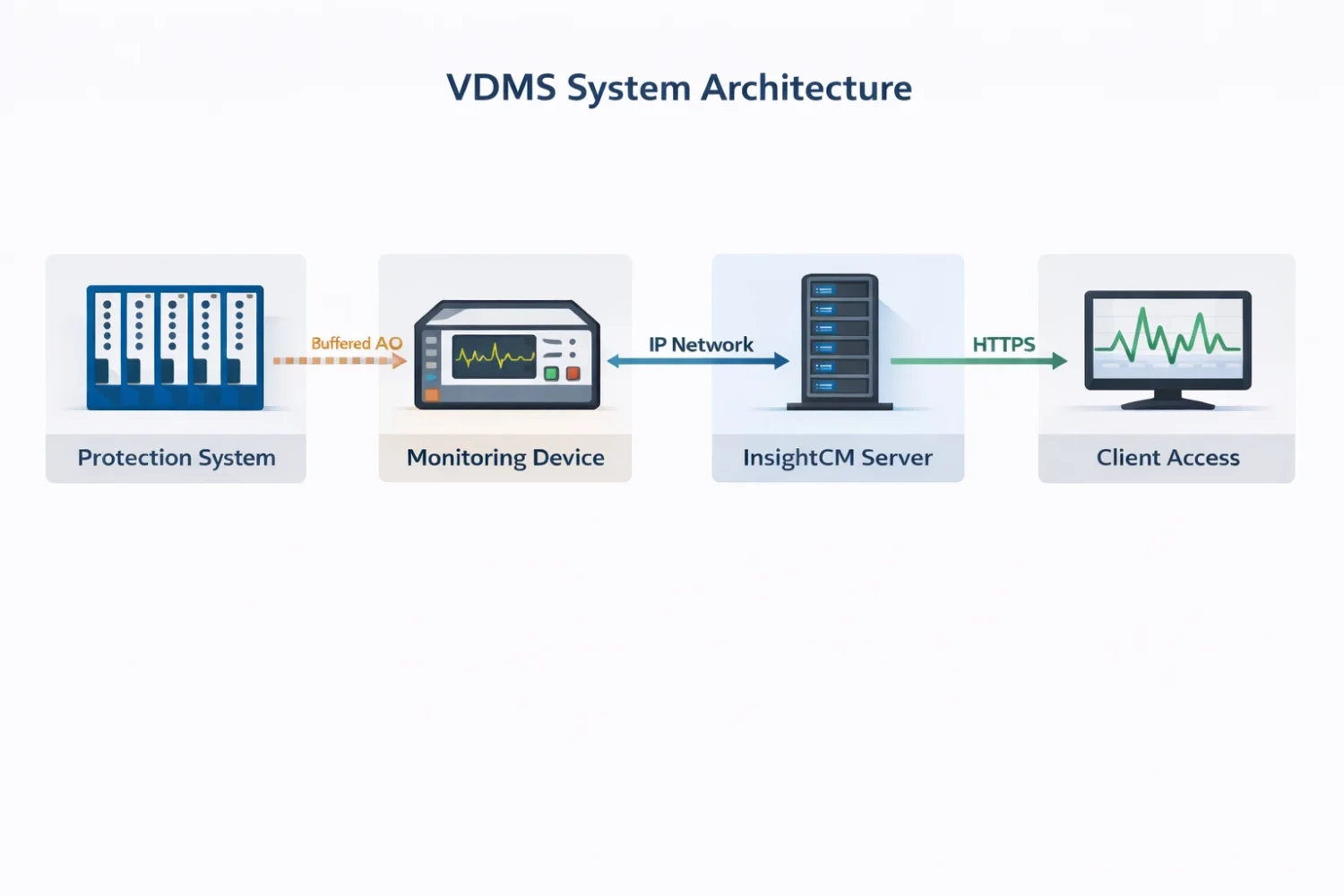

Critical assets such as generators, turbines, and other mission-critical rotating equipment carry the highest operational and financial risk in an industrial facility. When these machines fail, the consequences are severe—extended downtime, safety exposure, regulatory impact, and significant cost. Critical assets are typically protected by dedicated protection systems designed to trip equipment under unsafe conditions. These systems are intentionally isolated from business IT networks to minimize cyber risk and maintain operational integrity.

The Cutsforth VDMS (Vibration Data Management System) is purpose-built to continuously monitor these critical assets, delivering high-fidelity vibration data without compromising protection systems or cybersecurity.

- Early fault detection for bearings, rotors, and structural issues

- Reduced risk of catastrophic failures

- Leverage protection systems for valuable vibration and condition data

- Control networks remain isolated and uncompromised