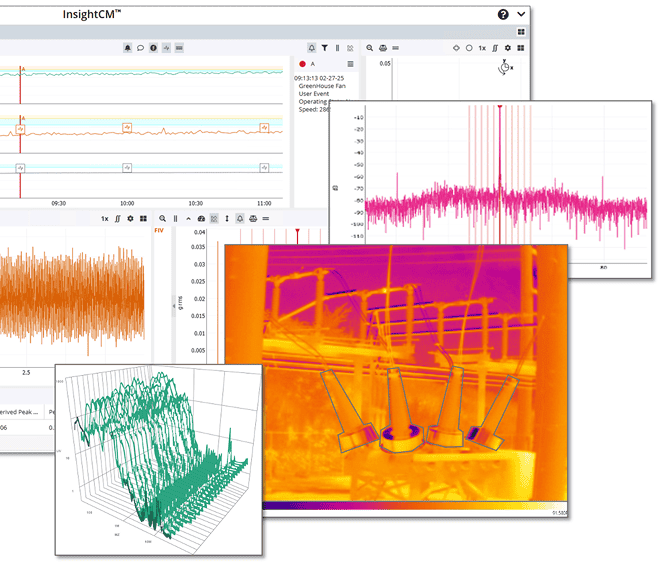

InsightCM: Your Window into Machine Health

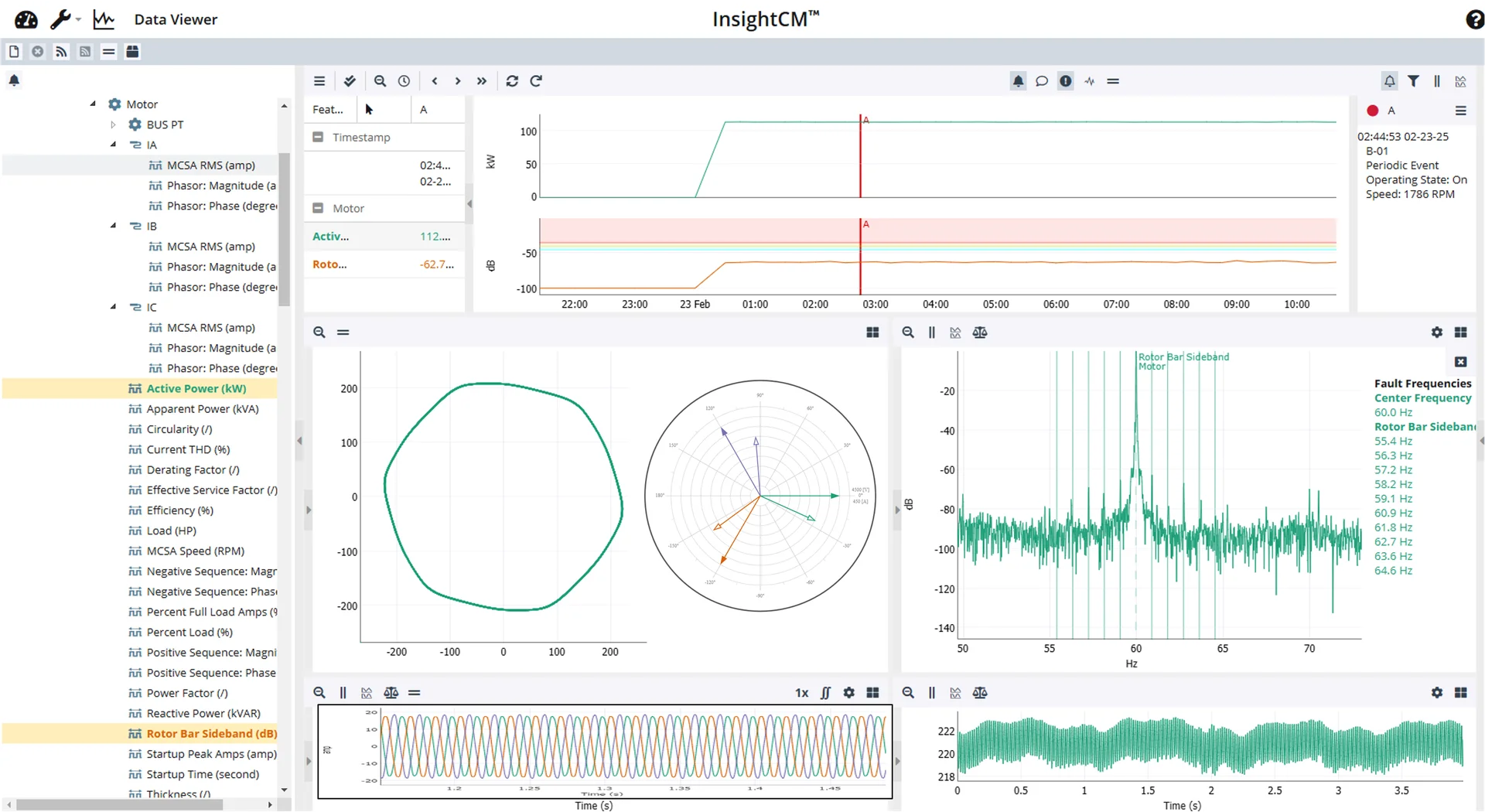

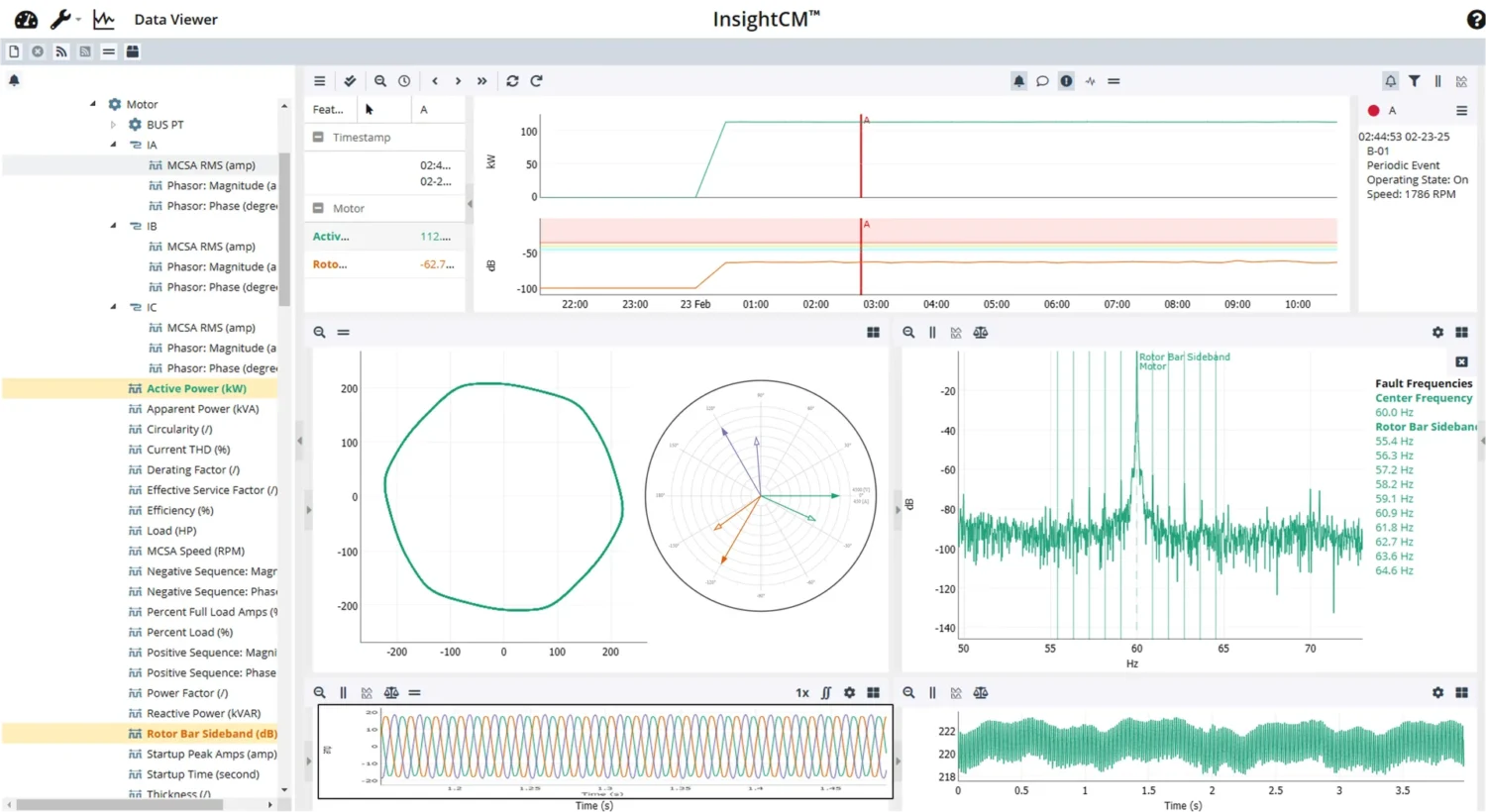

InsightCM combines multiphysics measurement data for a unified view of asset health. It captures and visualizes trend data, signal features, alarms, high-fidelity waveforms and process data under one pane of glass. Maintenance and reliability teams detect issues earlier, plan repairs more efficiently, and avoid unplanned downtime using InsightCM. With flexible connectivity, advanced analysis tools, and scalable architecture, InsightCM turns complex asset data into actionable, reliability insight.