The Cutsforth Platform

Beyond Vibration: Multiphysics Monitoring. Industry Expertise. One Platform.

Cutsforth is different: we combine multiphysics monitoring, expert-built diagnostic models, and a unified software platform with unmatched reliability expertise. Backed by decades of plant-floor experience and consulting services, our platform delivers a smarter, more effective path to reducing risk and improving asset performance.

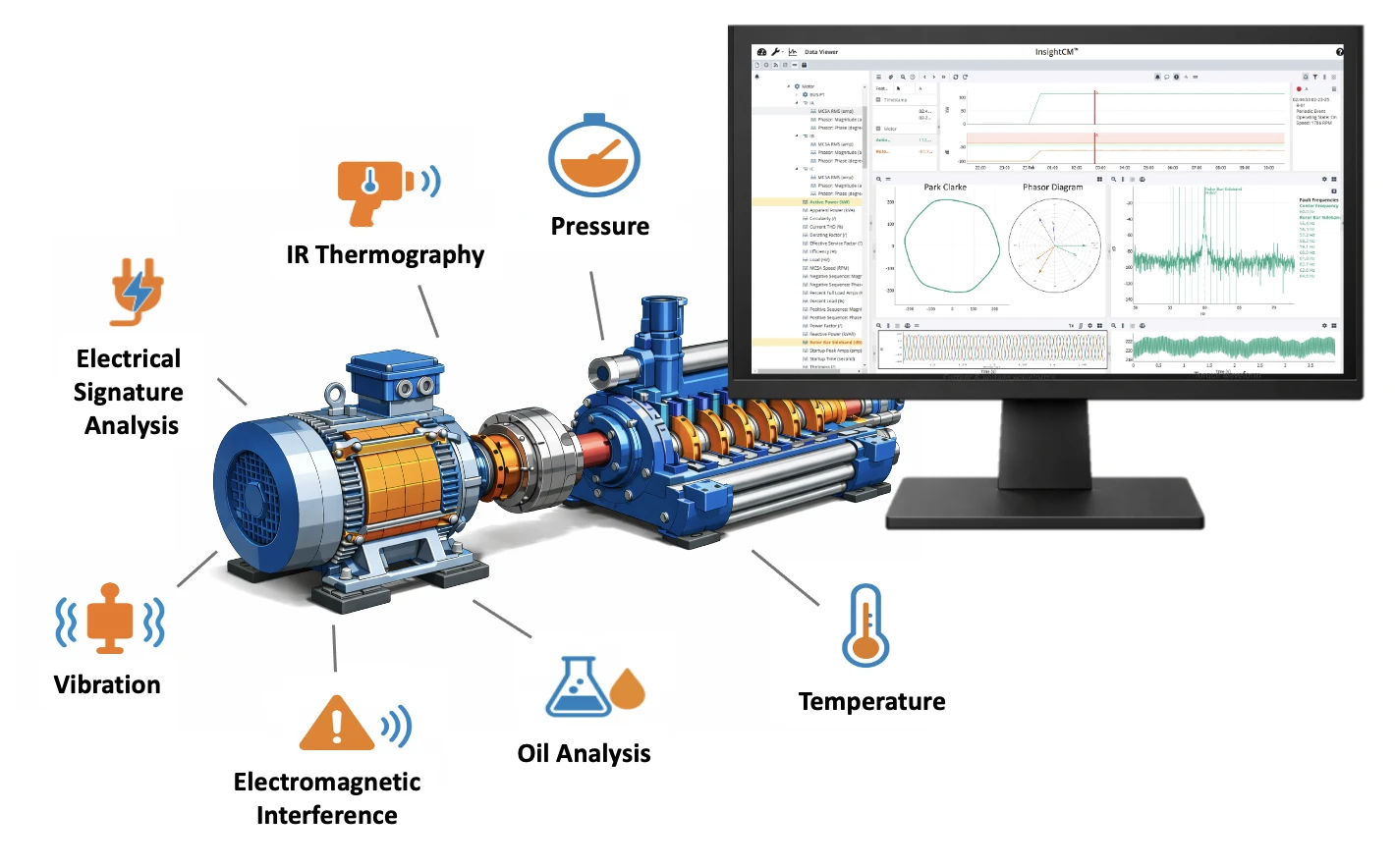

Multiphysics Monitoring

Our multiphysics monitoring approach fuses vibration, electrical signature analysis (ESA), electromagnetic interference (EMI), infrared (IR) thermography, generator monitoring, and process data to eliminate blind spots, reduce false alarms, and surface issues sooner.

- Applicable across rotating and electrical equipment

- Cross-signal correlation pinpoints root causes faster

- Multiple measurement technologies, wired or wireless.

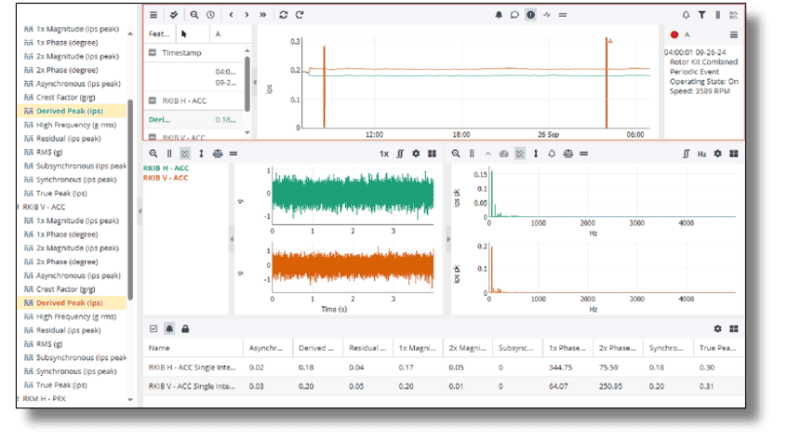

Unified Software Platform

Our InsightCM™ Condition Monitoring Platform ingests multiple sensor technology inputs, tracks alarms and trends, has full access to waveforms, and enterprise software connectivity — giving maintenance, reliability, and operations teams one workspace to see, decide, and act.

- Combine your measurements under one pane of glass

- View trends, alarms, and waveforms from your desktop

- Integration with third-party sensors, historians, and enterprise systems

Reliability Industry Leadership

Our services team literally wrote the book on reliability best practices with more than 600 years collective industry experience. We bring proven methods, practical training, and change management to make programs stick.

- Assessments and roadmaps grounded in field experience

- Standards-aligned practices adapted to your operation

- Lifecycle services from design and rollout to optimization

- Adoption programs that turn tools into outcomes

Trusted Partner

With decades of global deployments, we help operators build resilient monitoring programs that endure evolving production demands. Our innovative power generator hardware, monitoring systems, and services have made us a trusted name in the energy industry.

- Long-term relationships across asset-intensive industries

- More than 1,200 installations in more than 20 countries globally

- Modern technology backed by decades of industry expertise

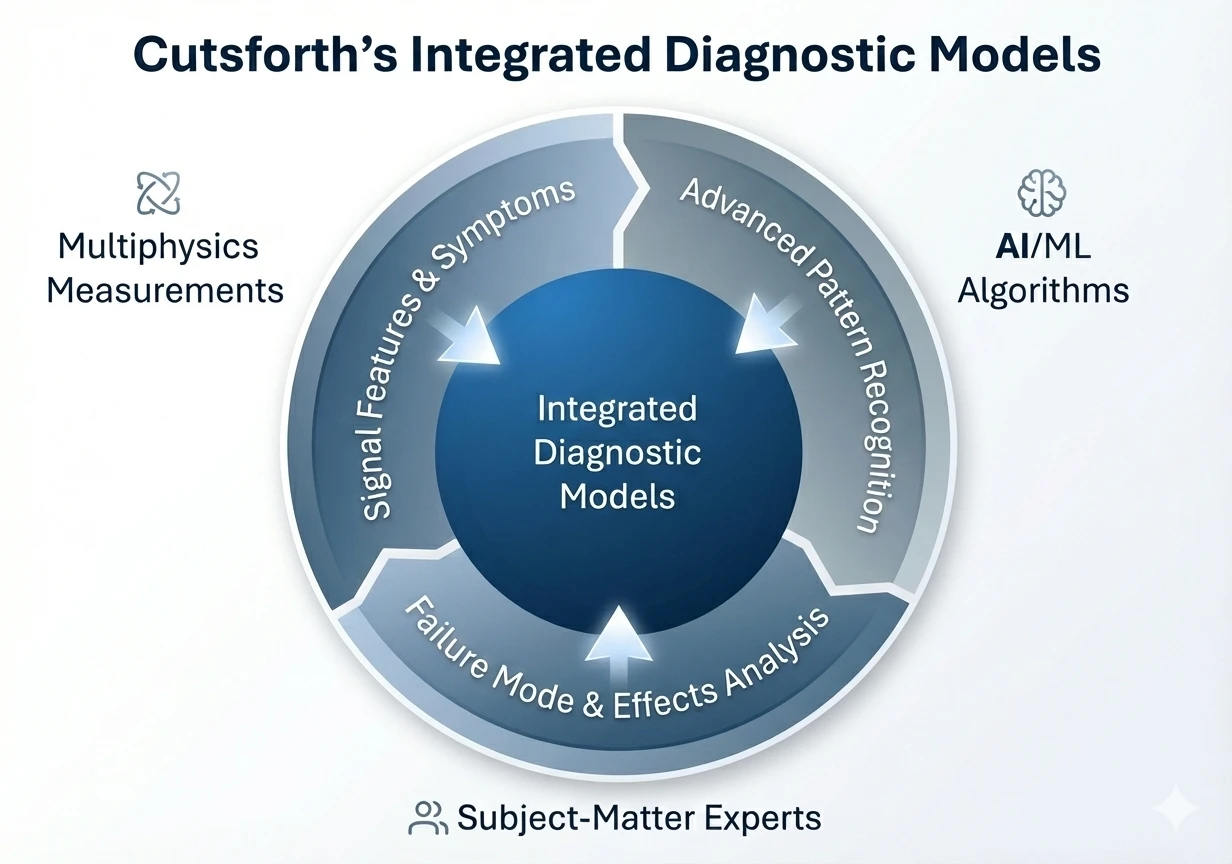

Integrated Diagnostic Models

Our library of expert, Integrated Diagnostic Models (IDMs) digitally document failure modes, their criticality, likelihood, and recommended sensors needed for more than 60+ asset models of common machinery used in process industries including generators, pumps, motors, turbines, and more Built from multiphysics measurements, plant-floor expertise, and AI tuning, IDMs deliver earlier, more accurate failure mode detection and diagnosis.

- Multiphysics: Models fuse vibration, electrical, thermal/IR, and process data for comprehensive failure mode coverage.

- Expert-built: Heuristics from subject-matter expert practitioners are embedded for real-world accuracy.

- Explainable: Every alert traces back to symptoms, signals, and model logic your team can trust.

See Integrated Diagnostic Models in Action

Multiphysics Monitoring FAQs

What is multiphysics monitoring?

Multiphysics monitoring combines multiple types of sensors — vibration, temperature, current, acoustic, and electromagnetic interference (EMI) — to detect early signs of machine degradation. By analyzing diverse data sources together, engineers gain a more complete and accurate view of asset health than vibration-only systems can provide.

Why is multiphysics monitoring better than single-measurement monitoring?

Each measurement type detects different failure symptoms. For example, temperature reveals thermal stress, vibration identifies mechanical imbalance, and current indicates electrical issues. Integrating these signals helps Cutsforth’s multiphysics monitoring platform find faults earlier and reduce false positives.

What measurement technologies are included in Cutsforth’s multiphysics monitoring approach?

Cutsforth’s condition monitoring systems can include vibration, electrical, EMI, acoustic, temperature, oil analysis, or really any measurement technology that is required for your plant. Our experts work with you to understand your critical assets, budget, and risk tolerance to design a monitoring strategy that uses the best combination of measurements for fault detection and diagnostics.

How does vibration monitoring help detect equipment faults?

Vibration sensors detect imbalance, misalignment, looseness, and bearing or gear faults by analyzing frequency patterns and amplitude trends over time.

How does electrical signature analysis help identify problems in rotating machinery?

Current and voltage signatures reveal issues such as rotor bar faults, winding insulation breakdown, and torque fluctuations — often before mechanical symptoms appear. In addition, electrical monitoring can detect power quality issues.

How does EMI (electromagnetic interference) monitoring improve condition monitoring?

EMI monitoring detects arcing, partial discharge, or other electrical events that create high-frequency disturbances. It can identify insulation breakdown or slip ring issues in rotating equipment long before visual inspection would.

Why does Cutsforth measure temperature directly as part of its multiphysics monitoring?

Direct temperature sensors confirm the thermal effects of faults and detect lubrication issues, cooling inefficiencies, or overload conditions. They also provide essential context for vibration and electrical measurements.

Does Cutsforth provide multiphysics monitoring hardware?

Cutsforth provides an integrated suite of wired and wireless sensors that capture vibration, temperature, current, and EMI data directly into the InsightCM platform. Our curated hardware offerings provide a wide variety of measurement options, and we can integrate third-party sensors into our platform as well for specific circumstances.

Integrated Diagnostic Models FAQs

What are Cutsforth’s Integrated Diagnostic Models?

Cutsforth’s integrated diagnostic models are digital representations of how specific equipment types fail. They combine expert knowledge, physics-based logic, and data-driven analytics to identify fault signatures automatically.

How are Cutsforth’s integrated diagnostic models different from generic AI algorithms?

Cutsforth’s integrated diagnostic models are built on decades of reliability expertise. Each model includes proven failure modes, associated condition indicators, and adaptive AI that learns from real-world plant data to improve detection accuracy. For each model, we go through an extensive process to capture and incorporate input from subject matter experts with decades of experience in condition monitoring. Their input is crucial to defining sensor coverage and priority models.

What types of equipment are covered by Cutsforth’s integrated diagnostic models?

Cutsforth provides diagnostic models for motors, generators, pumps, compressors, turbines, and transformers — each tailored to the unique failure mechanisms of those assets. Currently, there are more than 60 different industrial assets that have fault models.

What are the benefits of using Cutsforth’s integrated diagnostic models?

Cutsforth’s models deliver consistent, explainable, and automated insights. They reduce analyst workload, improve detection confidence, and accelerate troubleshooting compared to manual trend analysis. The technical knowledge captured in each model forms the foundation for our Reliability Services team. We use this knowledge to assess a customer’s current situation, perform gap analysis, and create a plan for them. In addition, the models are implemented in the Cutsforth unified software platform, powering the fault detection and diagnostic algorithms to deliver comprehensive, high-confidence analysis.

Ready to start monitoring with InsightCM?