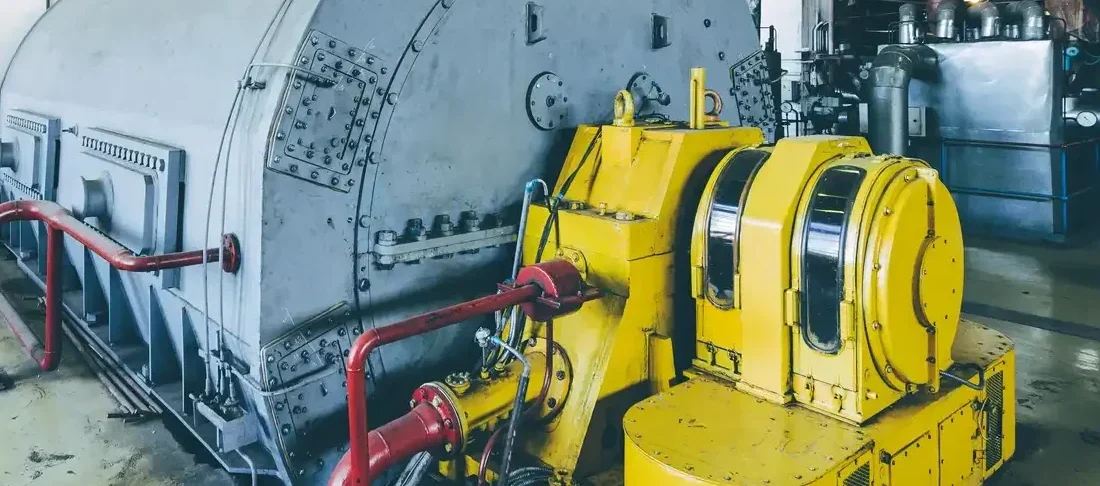

Overview

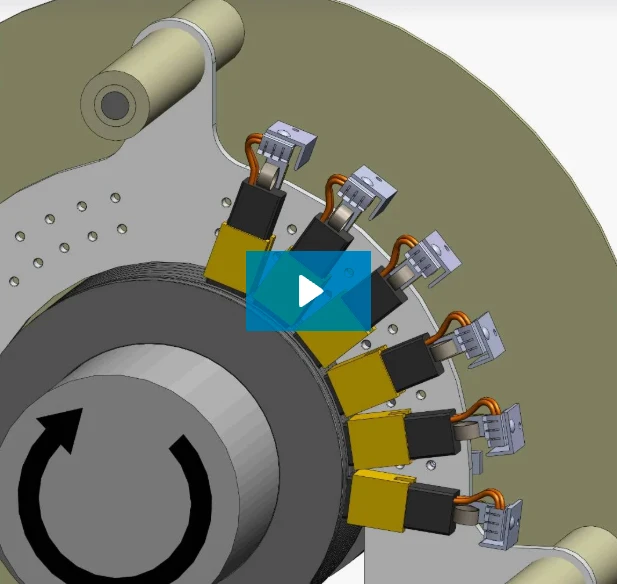

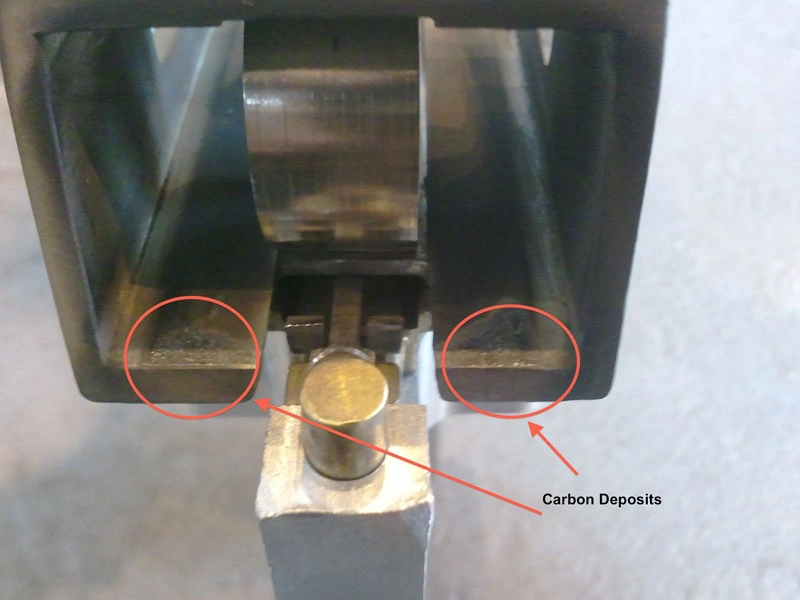

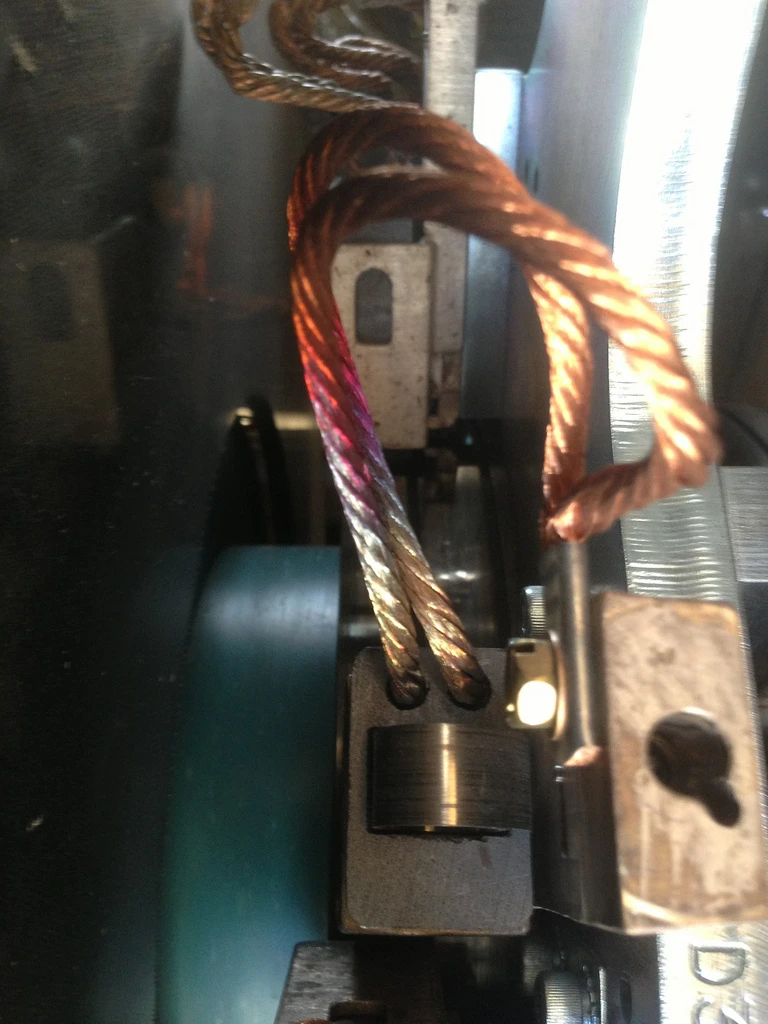

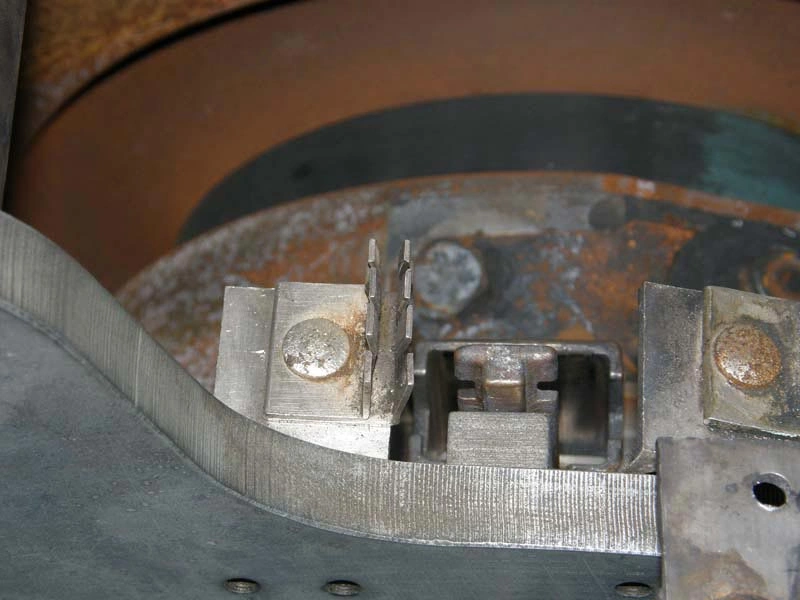

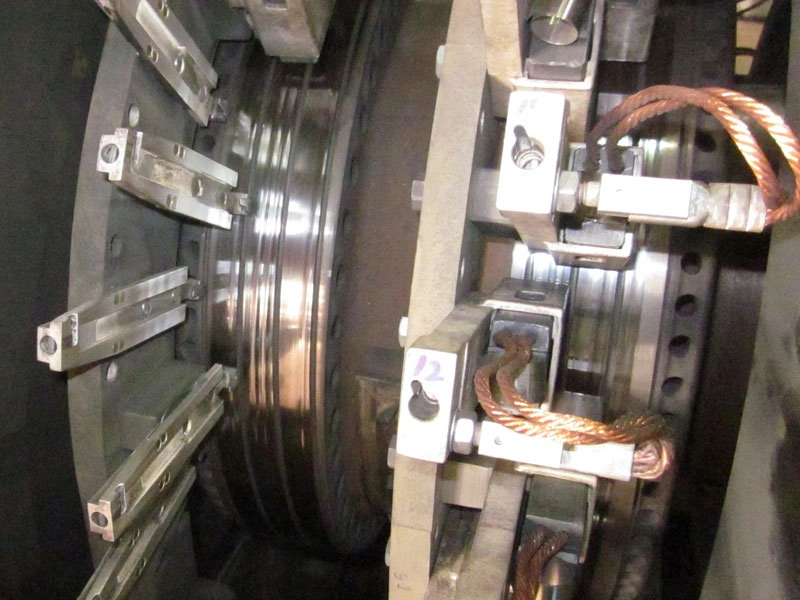

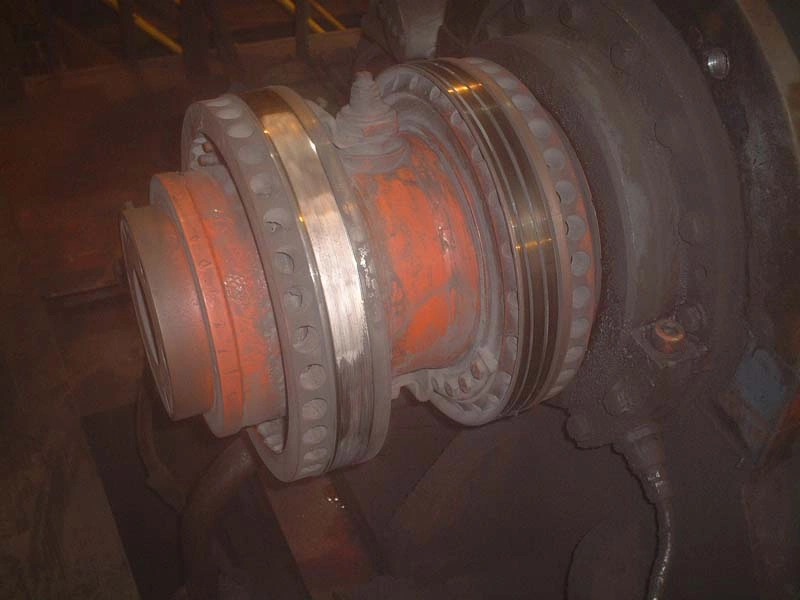

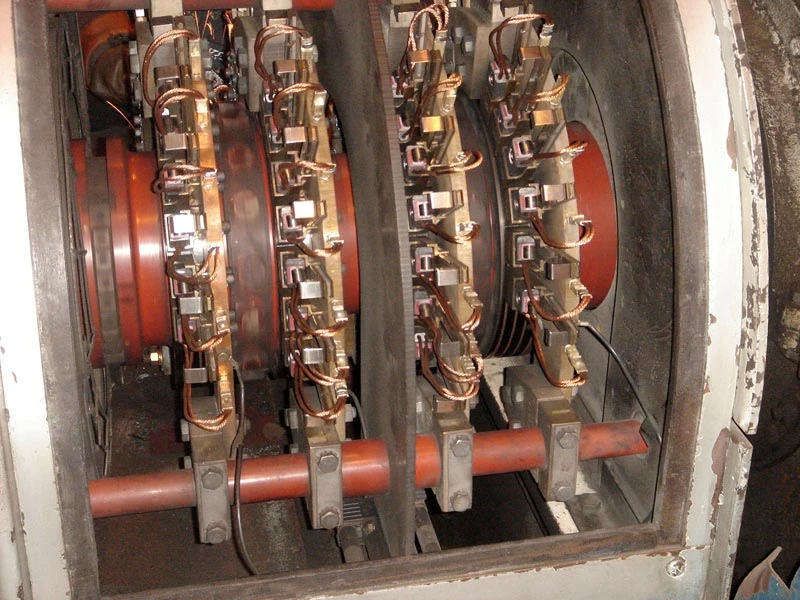

When it comes to resurfacing your collector rings and commutators, downtime is wasted time. So why take your unit off-line when Cutsforth Online Truing is more cost effective, less time consuming — and, in most cases, improves the brush-to-ring connection. Our online truing takes place at operational temperature and operational speed, so rings are ground in reference to the operational center, less material is removed, life expectancy is extended, and brush chatter and vibrations are reduced.