Prioritize Reliability

With age and demand on plants increasing and budgets and personnel in decline, organizing and implementing these programs can relieve pressure on finances, operations, and equipment

- Improving reliability of all assets throughout the fleet

- Increasing the capabilities of the maintenance, operations, and engineering workforce

- Optimizing capital expenditures across the fleet by increasing risk-informed decision making

- Improving thermal performance/net output

- Eliminating low value manual work activities and increase process efficiencies through digital transformation

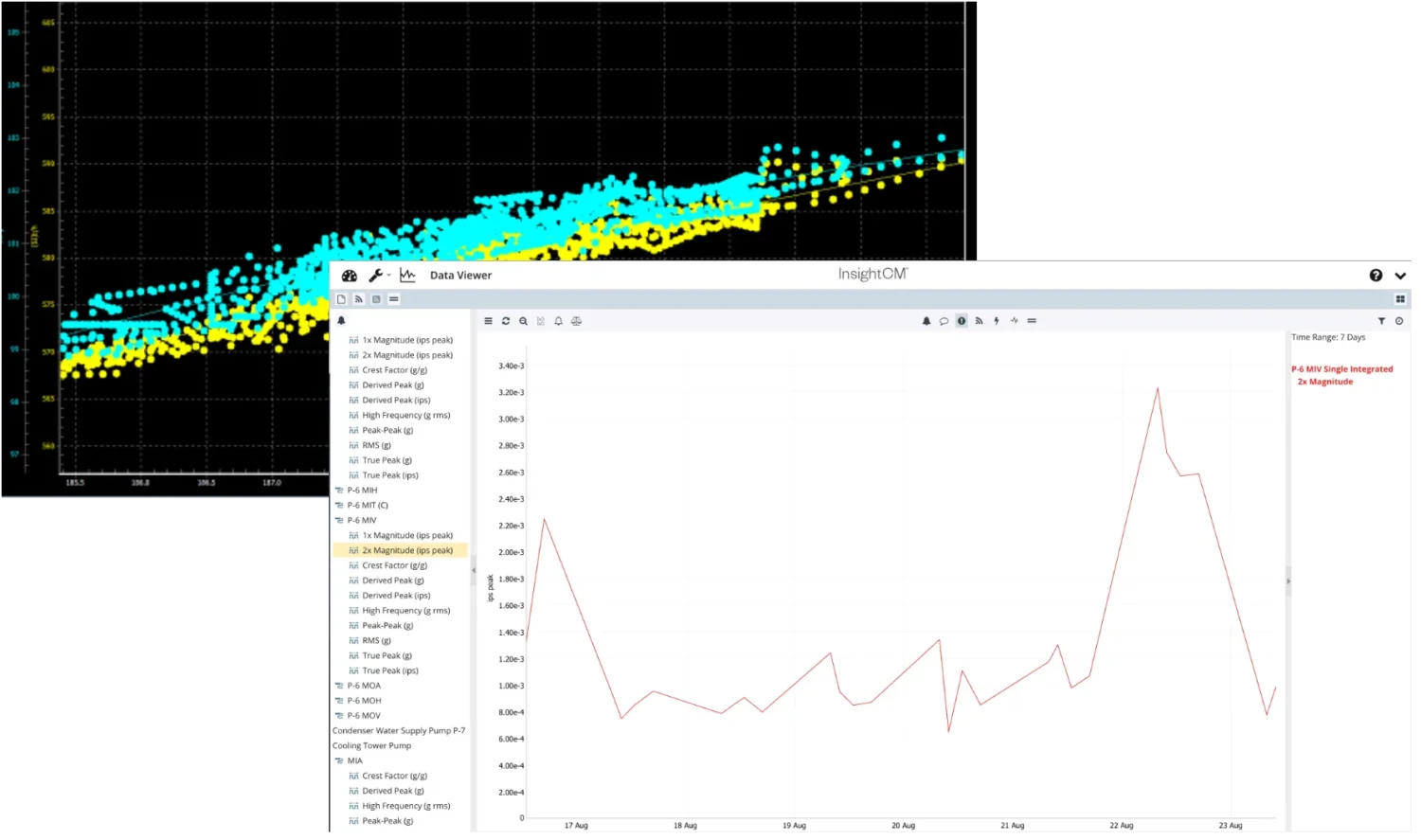

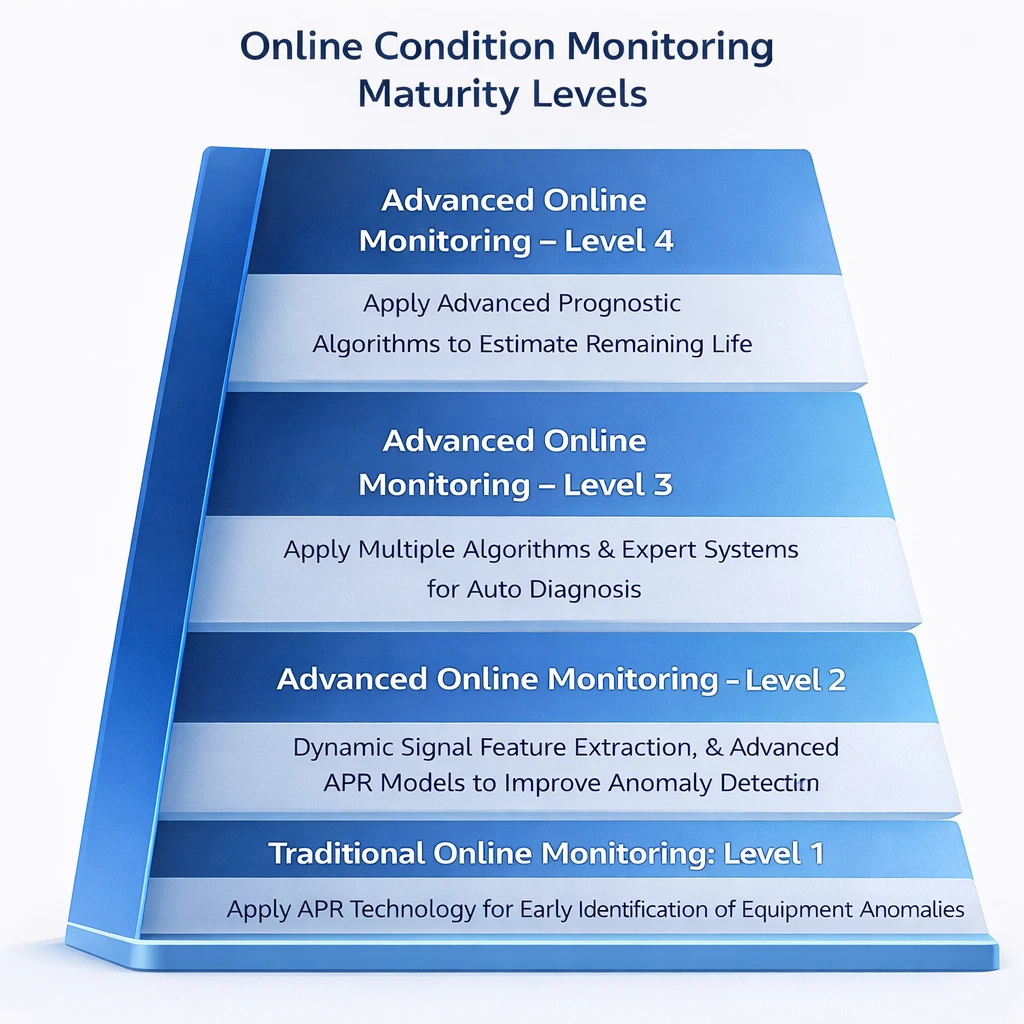

- Increasing advanced analytics capability to improve early detection and correction of equipment anomalies