The Challenge

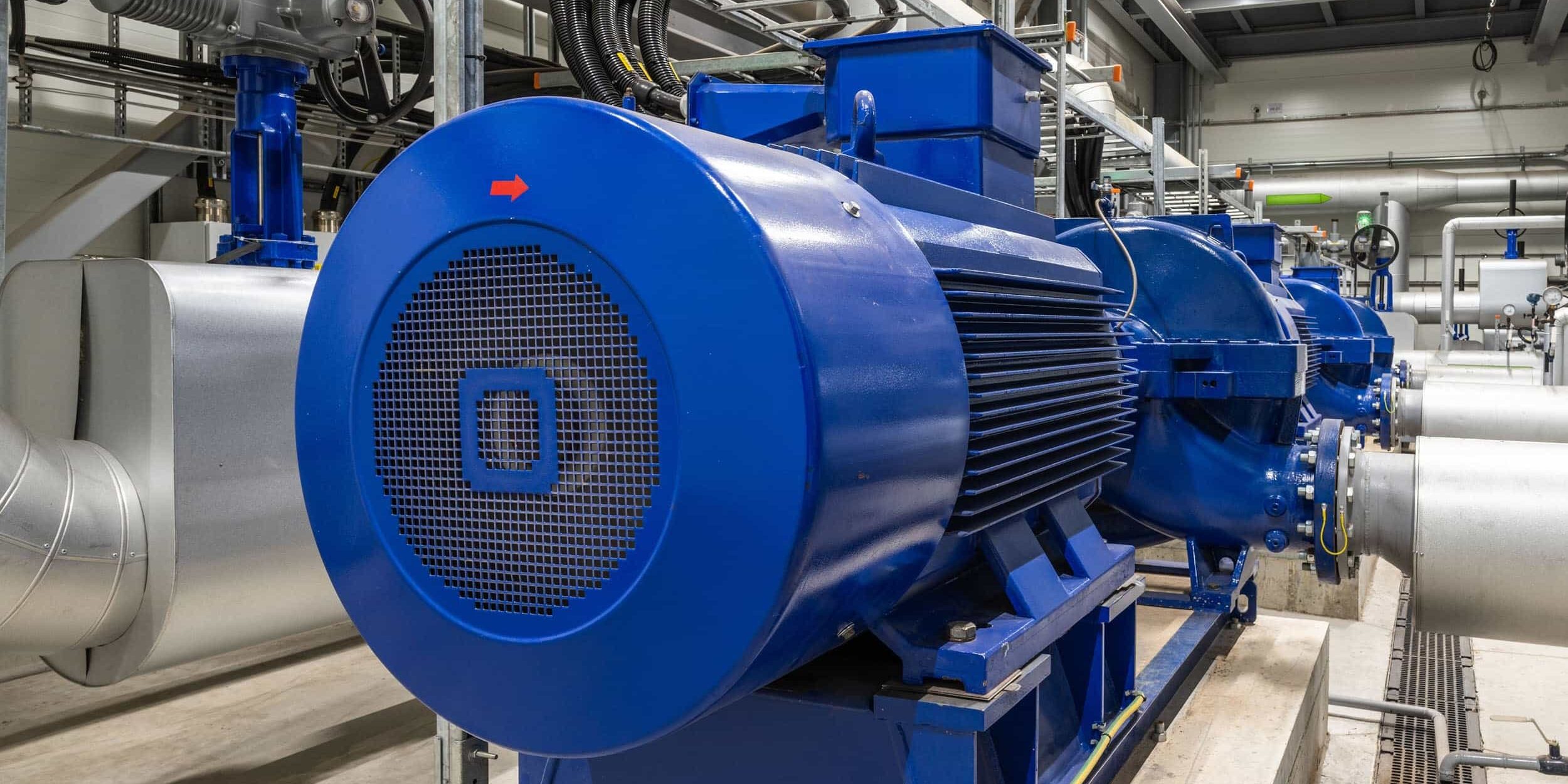

Pumps keep industry moving — circulating water, transferring chemicals, and feeding critical processes across plants. When pump performance slips, consequences spread quickly: reduced flow, increased energy consumption, equipment damage, or total production stoppage. Failures often cascade into safety hazards, environmental risks, and expensive emergency repairs.

Pumps Are Vital in Applications Like:

- Water and Wastewater: circulation, cooling, treatment

- Oil & Gas and Chemicals: process transfer, injection, loading systems

- Power Generation: boiler feedwater, cooling, lubrication systems

- Pulp & Paper and Mining: slurry handling, material processing

Effective monitoring isn’t just about protecting the pump — it’s about safeguarding the entire process it drives.