The Challenge

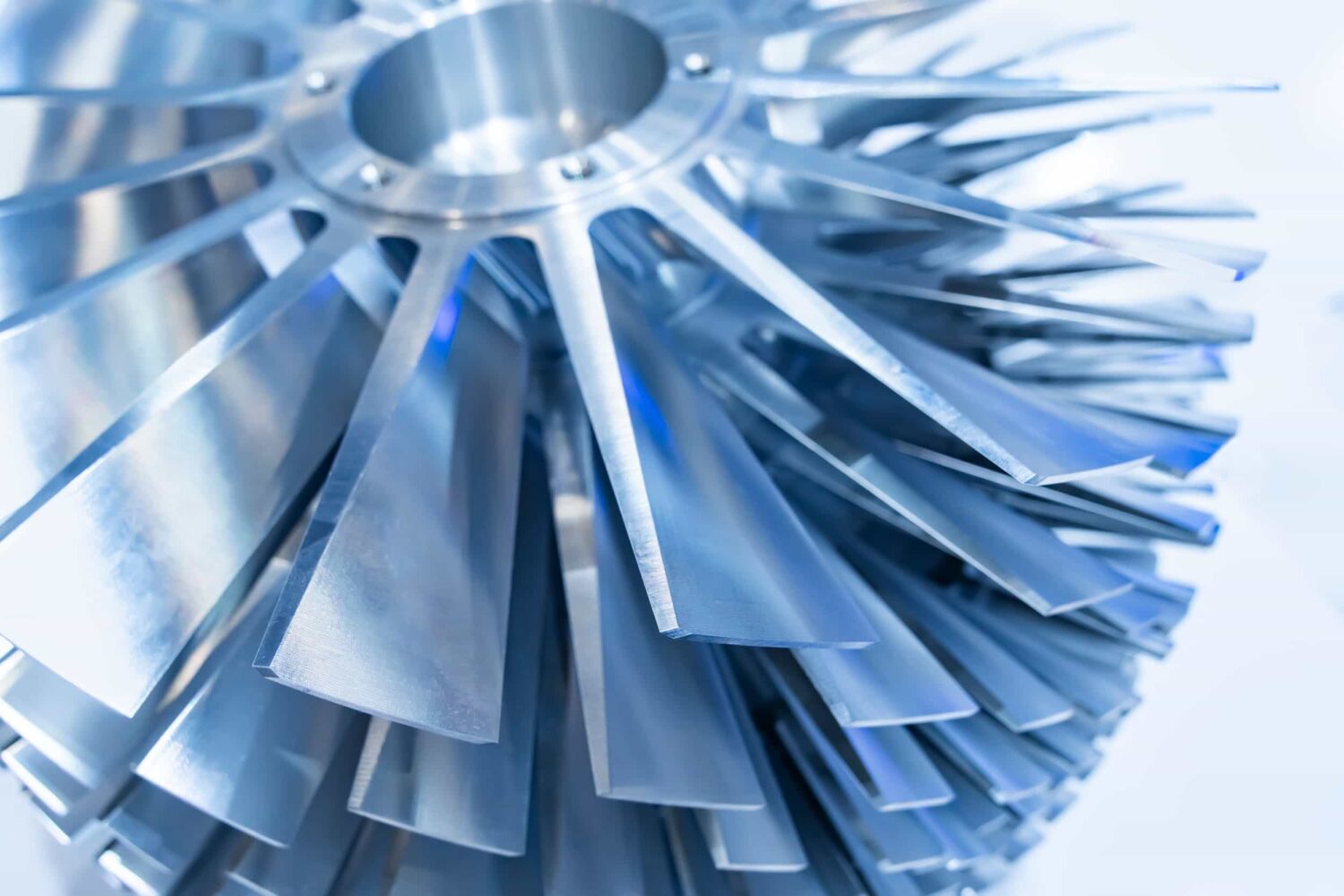

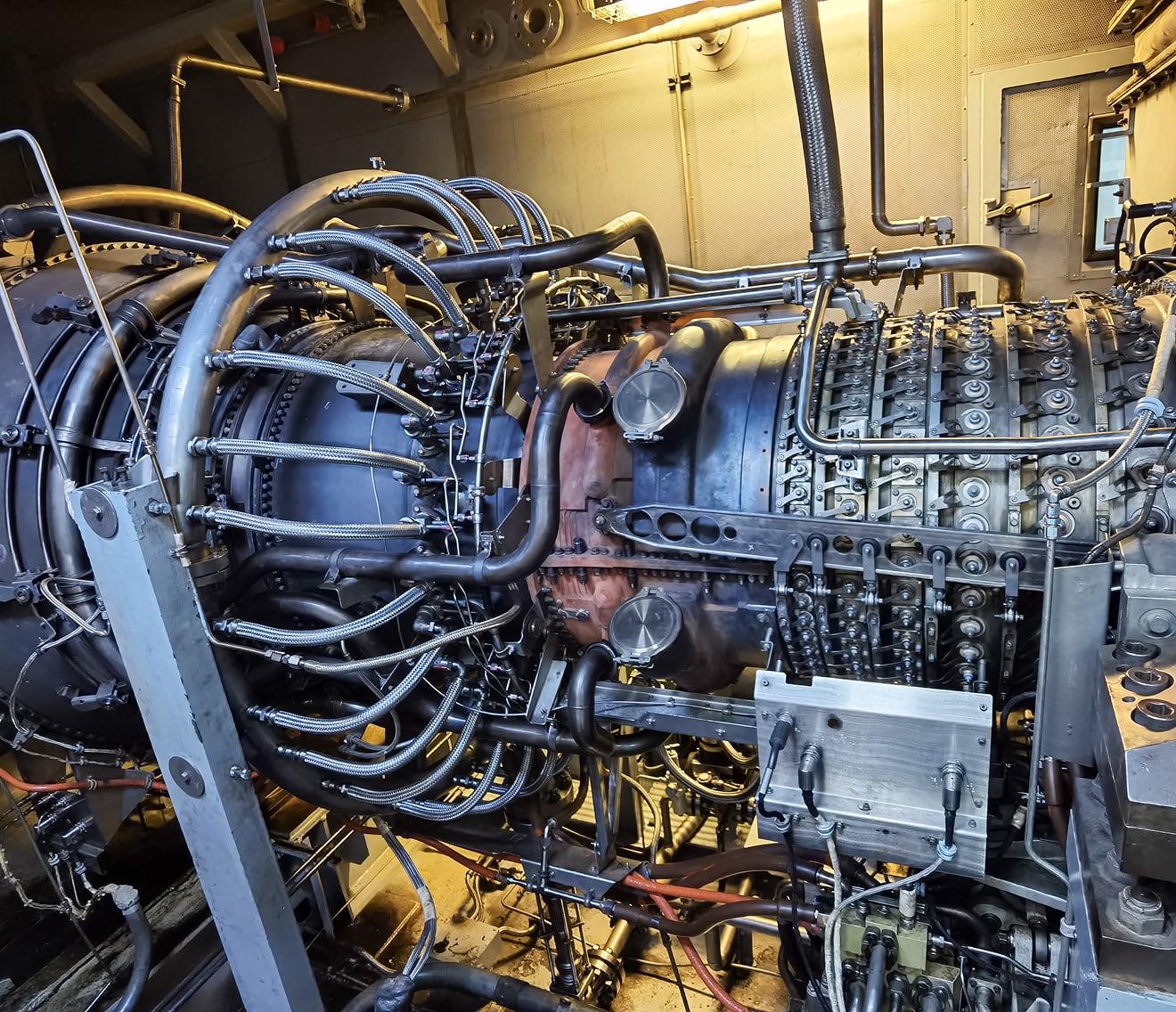

Turbomachinery—turbines, compressors, and expanders—are mission-critical assets in power and process industries. Operating at extreme speeds, pressures, and temperatures, even minor faults can escalate into costly failures, outages, or efficiency losses—making continuous monitoring essential.

Turbomachinery Is Essential in:

- Power Generation: steam, gas, and hydro turbines

- Oil & Gas: compressors, expanders, and turbo-pumps

- Petrochemicals & Refining: process compressors, blowers

- Industrial Processing: turbo-compressors for air and gases

When turbomachinery performance degrades, the stakes are higher: efficiency drops, reliability suffers, and entire plants can be forced offline.