Chemical Processing Condition Monitoring

Smarter Maintenance for Safer, More Reliable Chemical Production

Chemical Processing Reliability Concerns

Cutsforth’s condition-based monitoring systems help chemical plant operators protect and maintain critical assets including motors, pumps, and mixers. Our solutions provide an early-warning failure detection and diagnosis system, reduce unplanned equipment outages, and optimize chemical plant operations. With our help, you can address the chemical industry’s biggest reliability challenges:

- Aging Plant Equipment: Declining efficiency and rising maintenance demands

- Budgetary Pressures: Fewer resources to sustain performance

- Scarcity of Expertise: Loss of critical maintenance knowledge

- Growing Safety Issues: High-speed/high-voltage machinery endangers employees

Proven Performance and Experience

130% average ROI from monitoring system installations

600+ years of collective industry experience for expert consulting and implementation services

1200+ customers served in more than 20 countries

Why Cutsforth?

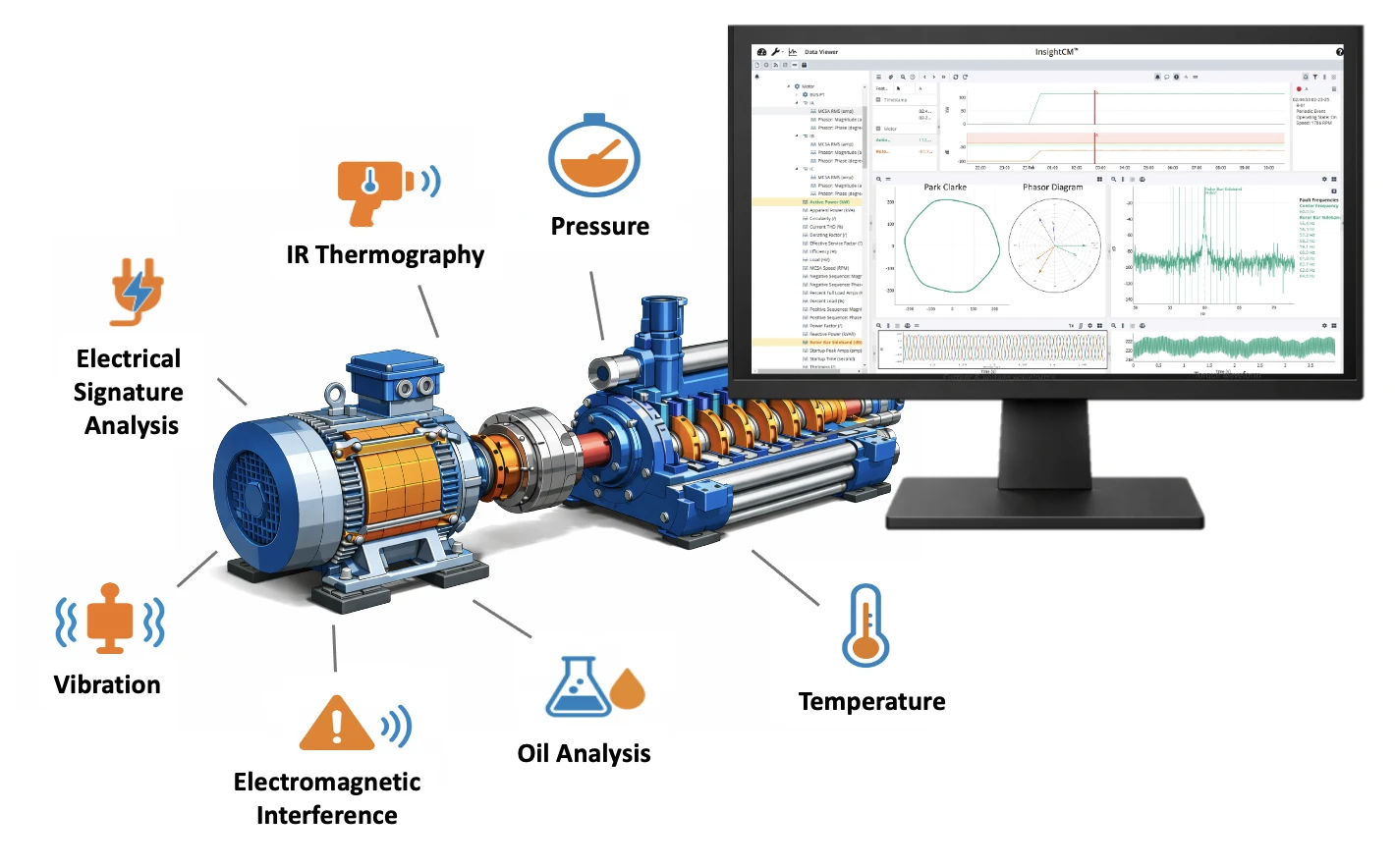

With our unique combination of multiphysics monitoring, industry expertise, and advanced software platform, you can transform your maintenance and reliability program.

- Multiphysics Monitoring: Vibration, electrical, thermal, EMI, and more

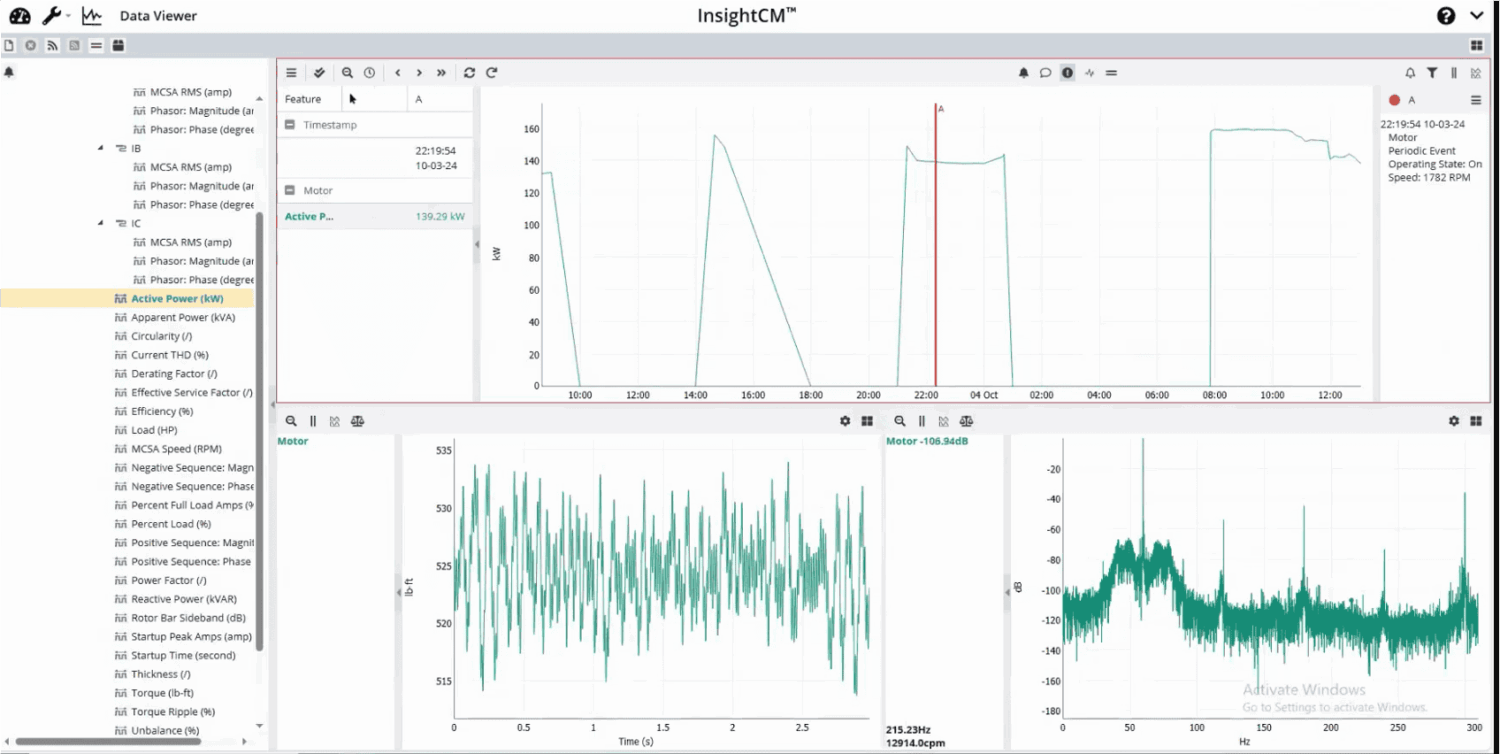

- Unified Software Platform: A single workspace for faster, more confident diagnosis

- Reliability Leadership: Experts who helped define reliability industry standards

- Trusted Partner: 35-year track record installing industrial systems worldwide

Build Your Strategy

- Leverage industry best practices and reliability standards

- Assess your asset coverage, sensor gaps, and processes and systems

- Chart a path that fits your timeline, budget, and appetite for risk

Monitor Facility Assets

- Meet NFPA 70B industry standards for equipment monitoring without adding manpower.

- Support ISO 20816 standards with continuous vibration, electrical, and thermal monitoring of pumps, compressors, and rotating assets.

- Improve OSHA 1910 and ATEX/IECEx safety compliance by reducing manual inspections in hazardous or energized process areas.

- Align with ISO 55000 and NFPA 70B/70E through multiphysics monitoring and documented, risk-based maintenance practices.

Detect and Diagnose Potential Faults

- Replace route-based or manual measurements for greater efficiency

- Detect and diagnose faults earlier to reduce the risk of downtime

- Increase confidence in maintenance and reliability decisions

Ready to start monitoring with InsightCM?