Pulp and Paper Condition Monitoring

Reduce Maintenance Costs, Lower Risks, and Improve Productivity with Multiphysics Predictive Maintenance

Pulp and Paper Challenges

Cutsforth’s condition-based monitoring capabilities help pulp and paper plants develop predictive-maintenance strategies for assets including pumps, compressors, turbines, motors, and generators. Our solutions reduce instances of unplanned equipment outages and provide greater efficiency in paper plant operations. With our help, you can respond to the paper industry’s biggest reliability challenges:

- Aging Plant Equipment: Declining efficiency and rising maintenance demands

- Budgetary Pressures: Fewer resources to sustain performance

- Scarcity of Expertise: Loss of critical maintenance knowledge

- High-Risk Equipment Damage: Greater risk of unexpected failures

Proven Performance and Experience

130% average ROI from monitoring system installations

600+ years of collective industry experience for expert consulting and implementation services

1200+ customers served in more than 20 countries

Why Cutsforth?

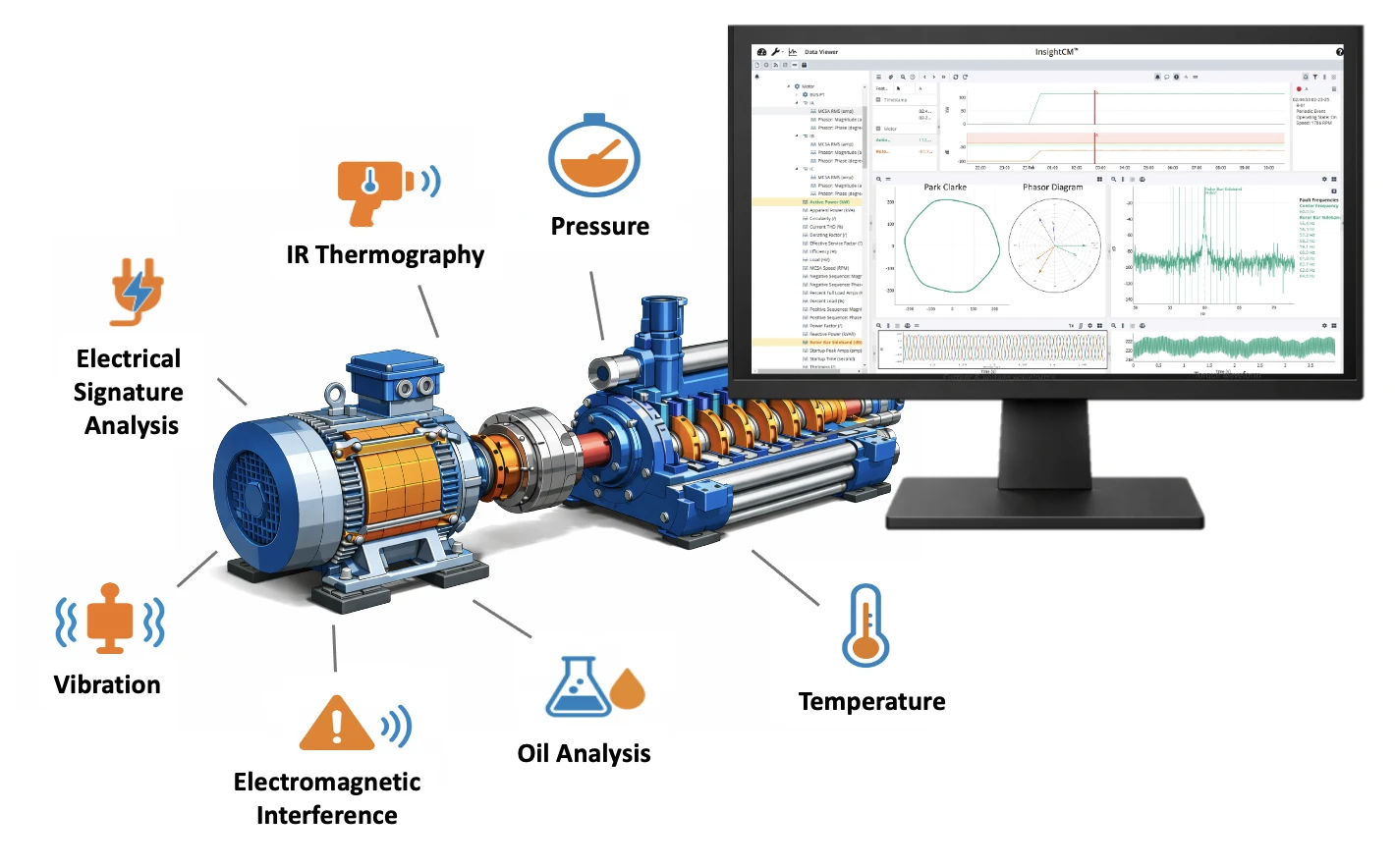

With our unique combination of multiphysics monitoring, industry expertise, and advanced software platform, you can transform your maintenance and reliability program.

- Multiphysics Monitoring: Vibration, electrical, thermal, EMI, and more

- Unified Software Platform: A single workspace for faster, more confident diagnosis

- Reliability Leadership: Experts who helped define reliability industry standards

- Trusted Partner: 35-year track record installing industrial systems worldwide

Build Your Strategy

- Leverage industry best practices and reliability standards

- Assess your asset coverage, sensor gaps, and processes and systems

- Chart a path that fits your timeline, budget, and appetite for risk

Monitor Facility Assets

- Replace route-based or manual measurements for greater efficiency

- Gain improved visibility and insights with multiphysics monitoring

- Mix wired and wireless sensors for an optimal solution

Detect and Diagnose Potential Faults

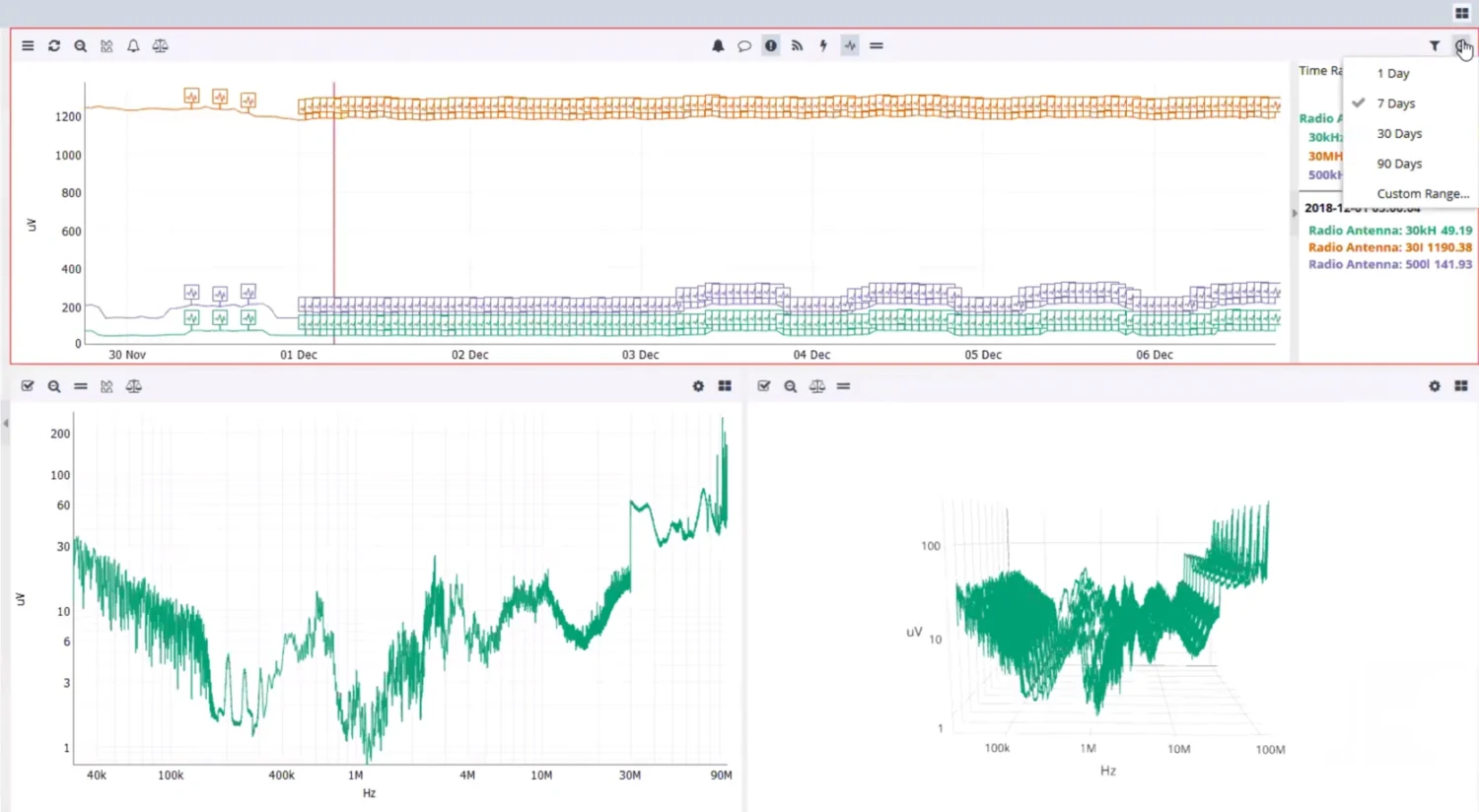

- Configure intelligent triggers, streaming, and alarms for detection

- Detect and diagnose faults earlier to reduce the risk of downtime

- Increase confidence in maintenance and reliability decisions

The monitoring solutions frequently employed in the pulp and paper industry include:

Electrical Signature Analysis (ESA)

Pulp and Paper Condition Monitoring Resources

Ready to start monitoring with InsightCM?